Barrel body cooling structure of hydrogen chloride synthetic furnace

A technology of heat dissipation structure and synthesis furnace, applied in the direction of chlorine/hydrogen chloride, etc., can solve the problems of poor heat dissipation effect and low heat exchange efficiency, and achieve the effect of improving heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

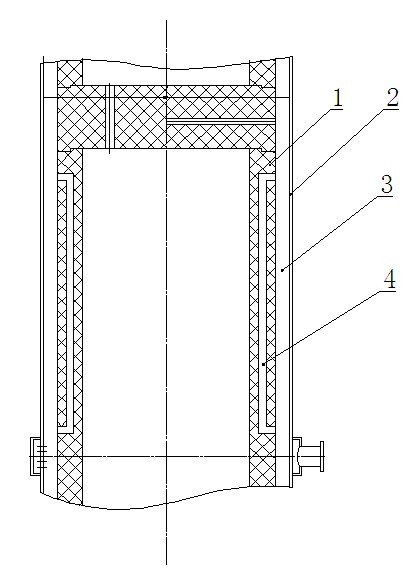

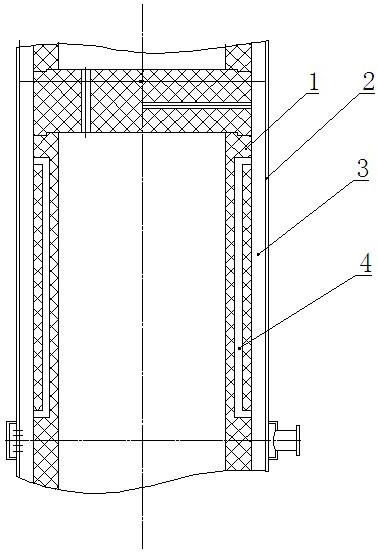

[0009] Such as figure 1 , 2 As shown, it includes a graphite cylinder 1, a steel shell 2, an interlayer 3, and a vertical flow channel 4.

[0010] The above-mentioned steel casing 2 is set in the graphite cylinder 1, the gap between the two is a cooling water interlayer 3, and a number of vertical flow channels 4 distributed in a ring are drilled on the wall of the graphite cylinder 1, and each vertical flow channel is connected to the interlayer. 3 connected.

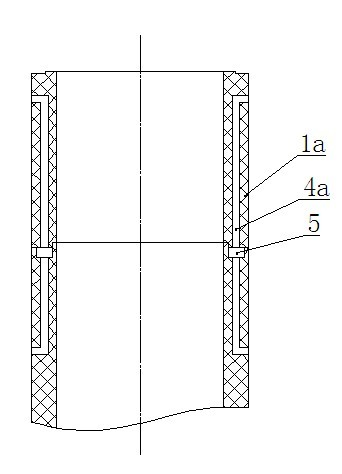

[0011] The graphite cylinder 1 is formed by overlapping and combining several graphite cylinder segments 1a, the vertical flow channels 4a of each graphite cylinder segment 1a are coaxially arranged, and a diameter is set on the upper or lower end surface of each graphite cylinder segment 1a. The annular groove 5 is larger than the diameter of the vertical flow channel 4a.

[0012] After the cooling water enters the vertical flow channel 4 of the graphite cylinder through the interlayer 3, it can be taken out quickl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com