Tunnel connecting passage construction method for directly cutting segment rings through pipe jacking machine

A communication channel and construction method technology, applied in tunnels, earthwork drilling, safety devices, etc., can solve problems such as soil collapse, inability to effectively control the stability of the excavation surface, and water gushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples.

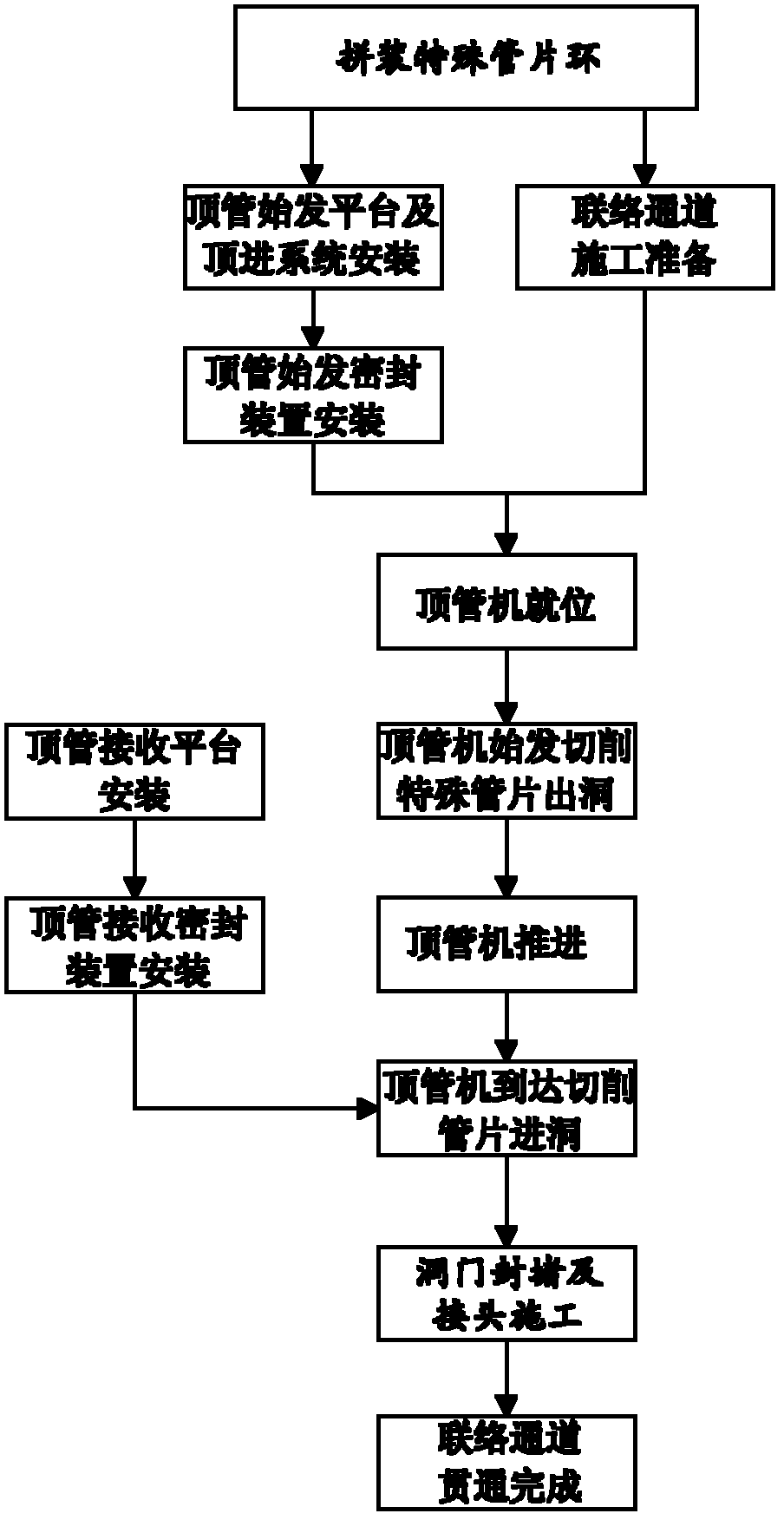

[0040] see figure 1 , a kind of pipe jacking direct cutting segment tunnel connection channel construction method of the present invention, comprises the following steps:

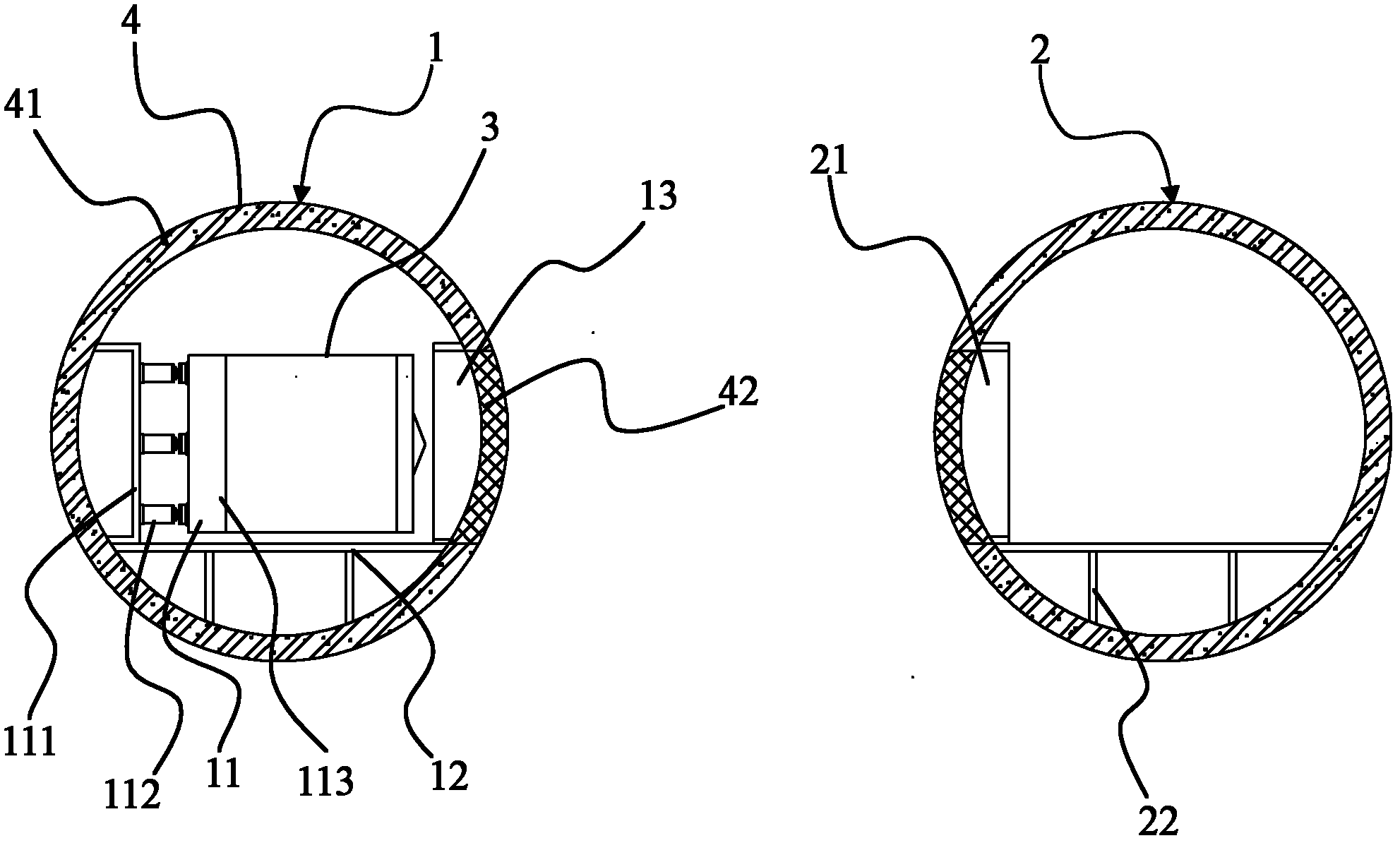

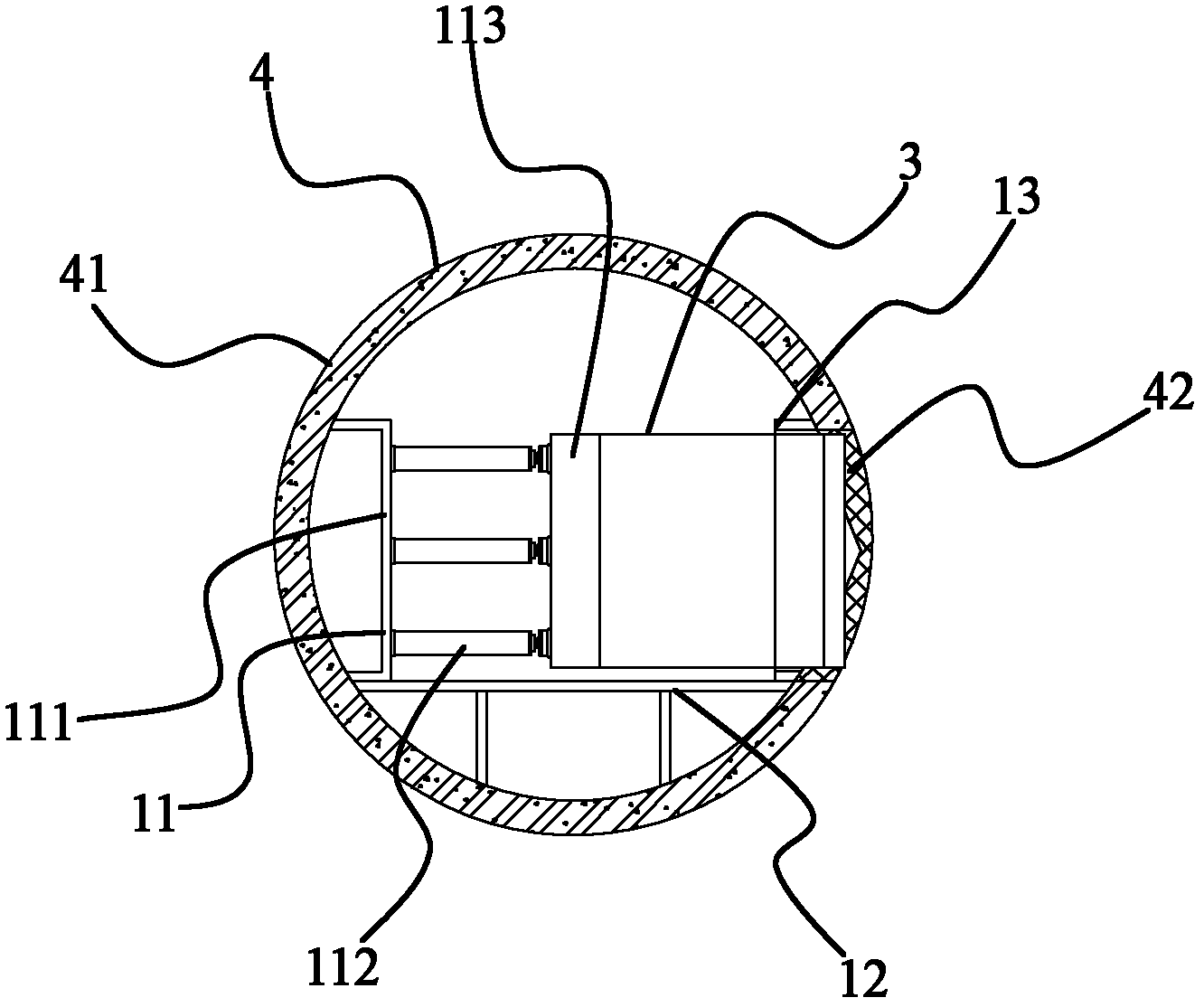

[0041] Firstly, a plurality of special segment rings 4 are assembled in preset positions of a first tunnel 1 and a second tunnel 2 respectively, and the special segment rings 4 include a cuttable portion 42;

[0042] Then, install a pipe jacking machine starting platform 12 and a jacking system 11 in the first tunnel 1, the jacking system 11 includes a jacking backrest 111, a jacking jack 112 and a pad 113; and Locate the position of an exit opening 14 on the special segment ring 4 of the first tunnel 1, locate the position of an entrance opening 23 on the special segment ring 4 of the second tunnel 2; and prepare for the construction of the communication channel 5;

[0043] Put a pipe jacking machine 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com