High-pressure and high-flow alternating-current servo direct-driven eccentric shaft type flow valve

An AC servo and AC servo motor technology, applied in the field of hydraulic valves, can solve problems such as oil pollution sensitivity, and achieve the effects of simple use, simple and reliable feedback coefficient adjustment, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

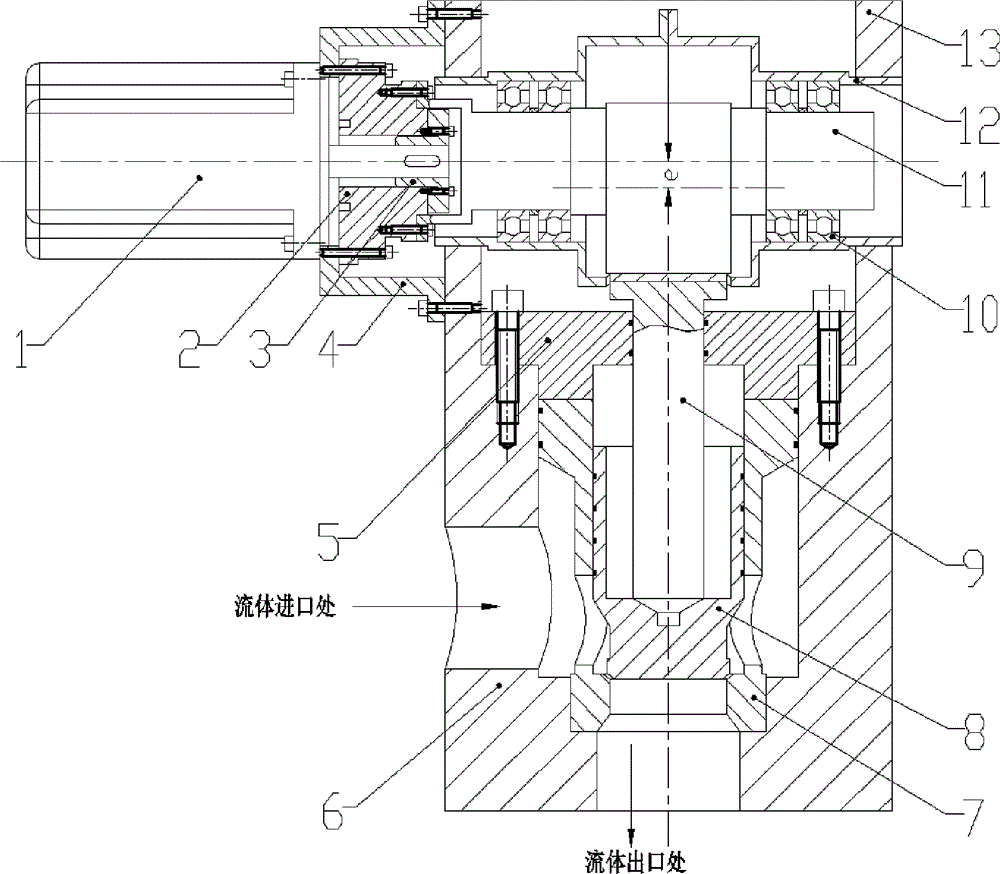

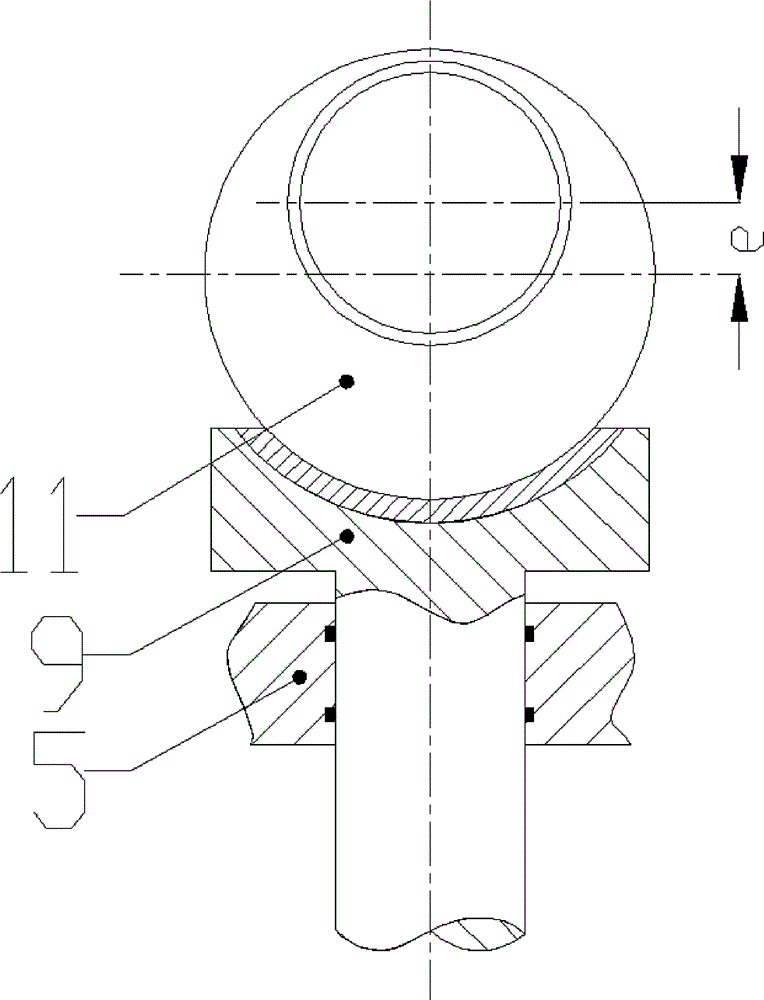

[0018] refer to figure 1 , a high-pressure and large-flow AC servo direct-drive eccentric shaft flow valve, including an AC servo motor 1, a harmonic reducer 2, a coupling 3, a bell housing 4, an end cover 5, a valve seat 6, a valve sleeve 7, Spool 8, connecting rod 9, bearing 10, eccentric crankshaft 11, bearing cover 12, cover plate 13, the output shaft of AC servo motor 1 is connected to the input end of harmonic reducer 2 through coupling 3, and the harmonic reducer The output end of 2 is connected with the eccentric crankshaft 11 by screws, and the eccentric part of the eccentric crankshaft 11 cooperates with the bearing shell of the connecting rod 9. The two shoulders of the eccentric crankshaft 11 are respectively provided with two pairs of four bearings 10, and the bearings 10 use a pair of two bearings in total. The cover 12 is fixed, the shoulder of the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com