Light-mixing-type polycrystalline packaging structure

A packaging structure and light mixing technology, applied in the direction of light source, lighting device, light source fixing, etc., can solve the problem of insufficient color rendering, and achieve the effect of improving color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

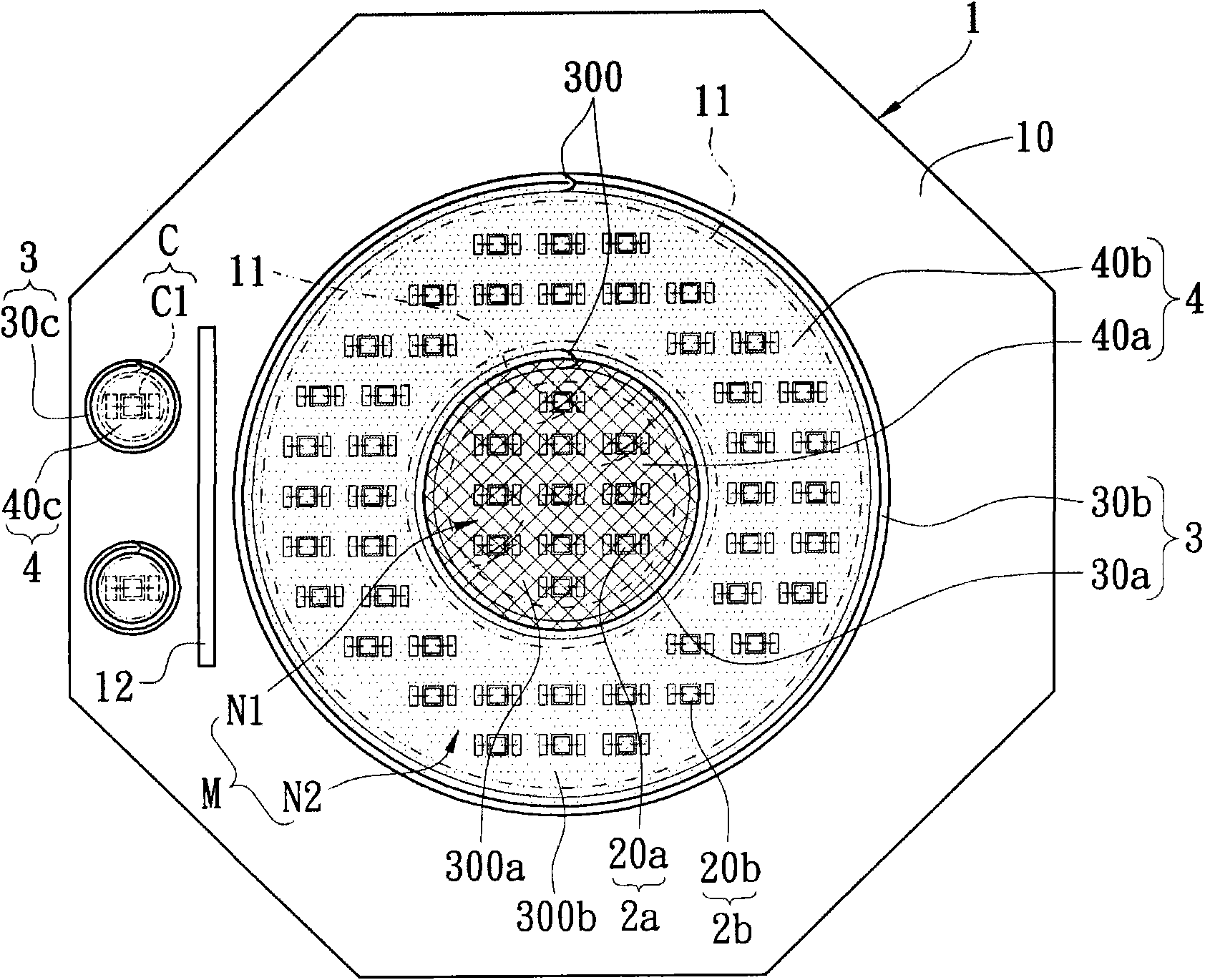

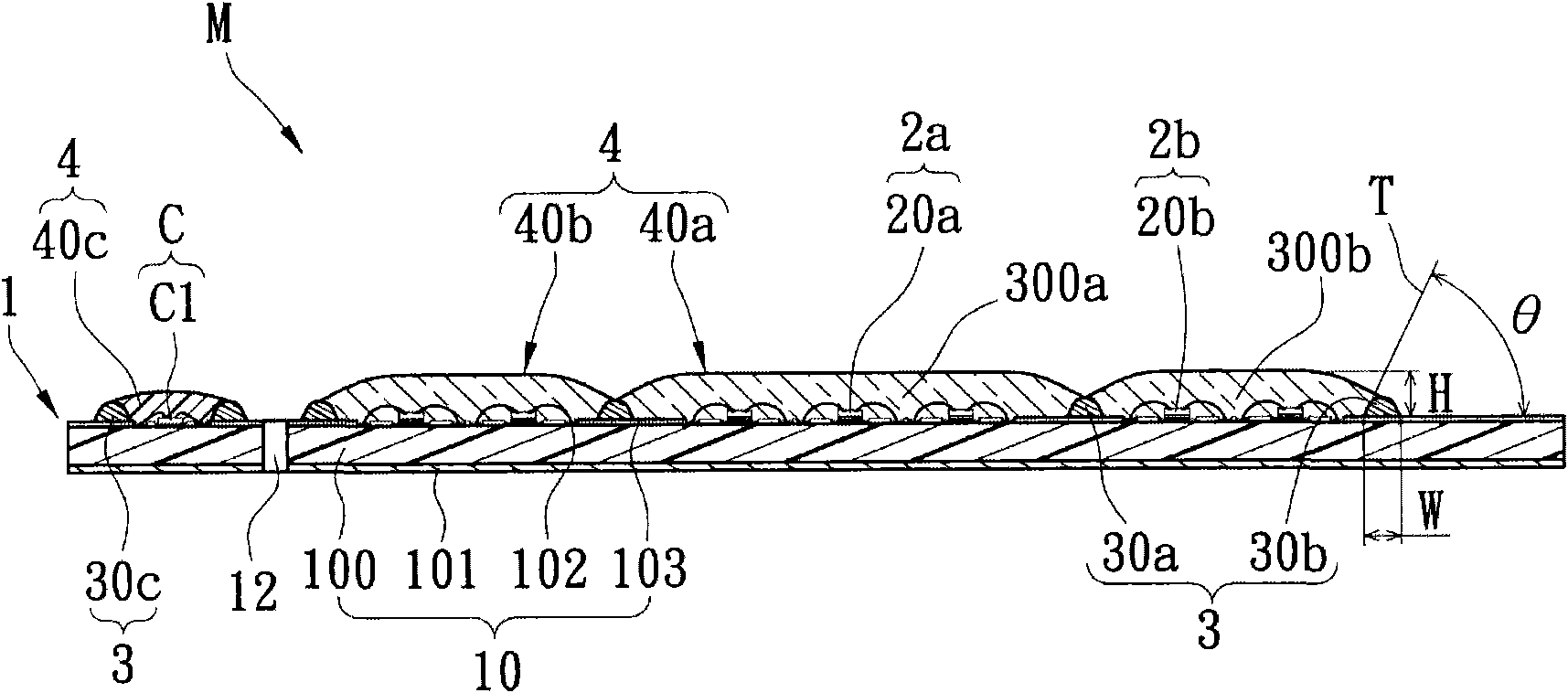

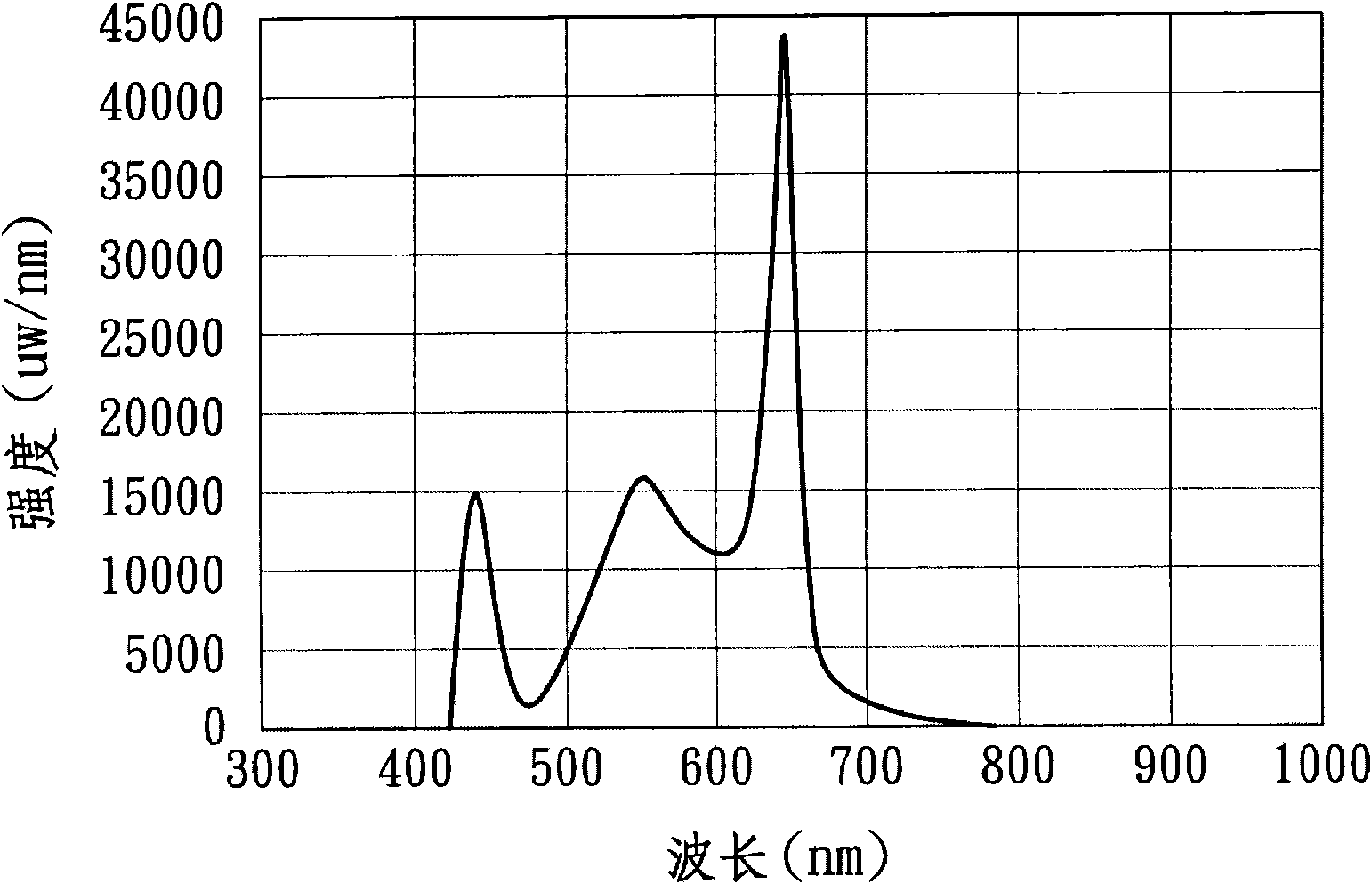

[0078] see Figure 1A and Figure 1B As shown, Embodiment 1 of the present invention provides a light-mixing polycrystalline packaging structure M, which includes: a substrate unit 1 , a light emitting unit, a frame unit 3 and a packaging unit 4 .

[0079] The substrate unit 1 has at least one substrate body 10 and at least two crystal mounting regions 11 disposed on the upper surface of the substrate body 10 . In addition, the substrate body 10 has a circuit substrate 100, a heat dissipation layer 101 disposed on the bottom of the circuit substrate 100, a plurality of conductive pads 102 disposed on the upper surface of the circuit substrate 100, and a plurality of conductive pads 102 disposed on the upper surface of the circuit substrate 100 for exposing The insulating layer 103 of the plurality of conductive pads 102 . Therefore, the heat dissipation layer 101 can be used to increase the heat dissipation performance of the circuit substrate 100 , and the plurality of insul...

Embodiment 2

[0092] see figure 2 As shown, Embodiment 2 of the present invention provides a light-mixing polycrystalline packaging structure M. Depend on figure 2 Comparison with Fig. 1 shows that the biggest difference between Embodiment 2 and Embodiment 1 of the present invention is that in Embodiment 2, the positions of the first light-emitting module 2a and the second light-emitting module 2b are reversed, so that the first light-emitting module 2a placed in the outer circle, and the second light-emitting module 2b is placed in the inner circle. In other words, the first surrounding frame glue 30a surrounds the second light emitting module 2b, the second surrounding frame glue 30b surrounds the first light emitting module 2a and the first surrounding frame glue 30a, and the first light emitting module 2a is arranged on the first surrounding frame Between the frame glue 30a and the second surrounding frame glue 30b. The fluorescent colloid 40b is confined in the first colloid limit...

Embodiment 3

[0095] see image 3 As shown, Embodiment 3 of the present invention provides a light-mixing polycrystalline packaging structure M, which includes: a substrate unit 1 , a light emitting unit, a frame unit 3 and a packaging unit 4 . The biggest difference between Embodiment 3 of the present invention and Embodiment 1 is that in Embodiment 3, according to different design requirements, the first surrounding frame colloid 30a and the second surrounding frame colloid 30b can be transparent colloid or fluorescent colloid one of them. For example, the present invention can selectively add fluorescent powder in the first surrounding frame colloid 30a and the second surrounding frame colloid 30b according to different requirements, so that the light source can be guided to the transparent colloid 40a and the fluorescent powder. Light is emitted between the colloids 40b (shown by upward or slanting arrows in the figure), thereby reducing the dark band between the transparent colloid 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com