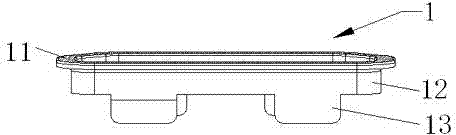

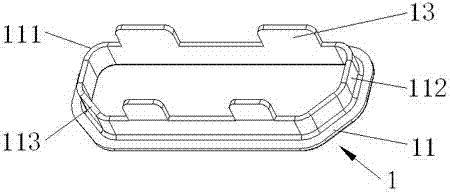

Mirror polishing method of mobile phone USB slot panel and mobile phone USB slot component

A technology of mirror grinding and slotting, which is applied to grinding machine tools, grinding devices, telephone structures, etc., can solve the problems of increased complexity, scrapped mobile phones, short circuit of mobile phone PCB boards, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0029] The method for grinding the mirror surface of the USB slot panel of the mobile phone includes the following steps:

[0030] (1) Stamping and forming mobile phone USB slot components;

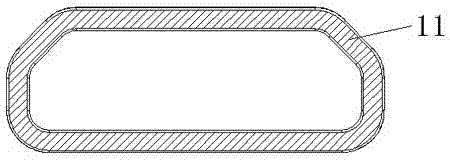

[0031] (2) Polishing the USB slot panel of the mobile phone to grind out a surface with a mirror effect;

[0032] (2.1) Place the USB slot panel of the mobile phone to be ground on a flat grinding disc or jig. The grinding disc rotates counterclockwise, and the jig drives the grinding workpiece to rotate clockwise. The 2000# alumina solution between the workpiece and the grinding disc is used for relative running friction. Through the rotation of the grinding disc and the pressure applied to the grinding workpiece, the surface of the USB slot panel of the mobile phone is cut with 2000# alumina sand grains;

[0033] (2.2) Add 8000# alumina solution when rotating, and use 800...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com