Protective film-attaching method and protective film

A protective film and attachment technology, which is applied to flexible coverings, packaging, wrapping paper, etc., can solve the problems of difficult separation of protective film and release film, affecting production efficiency and yield, and insufficient air intake, so as to avoid Air leakage, reduced defect rate, and increased adsorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

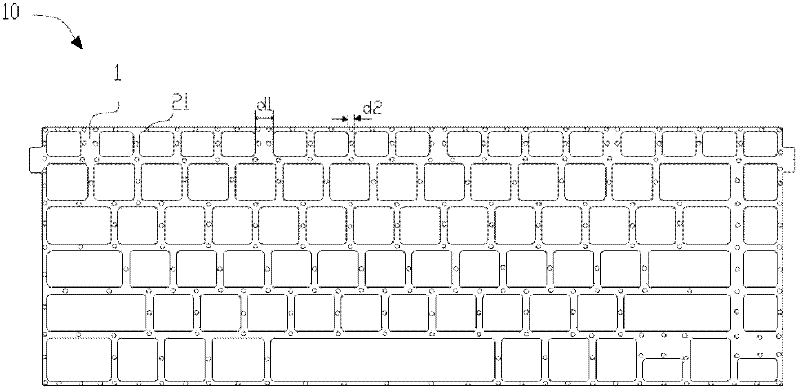

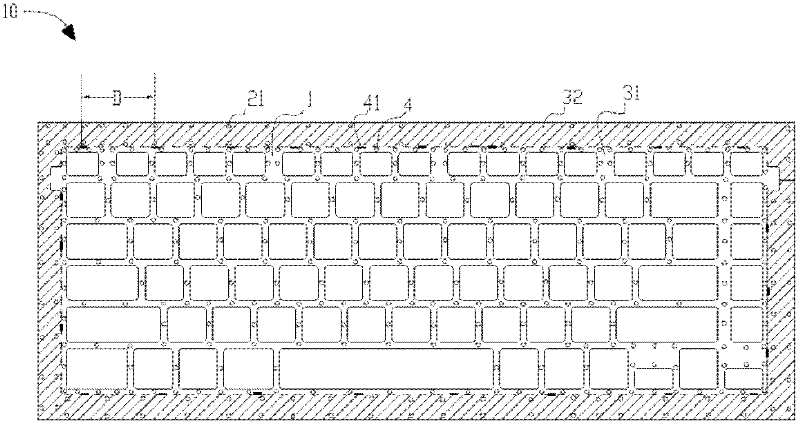

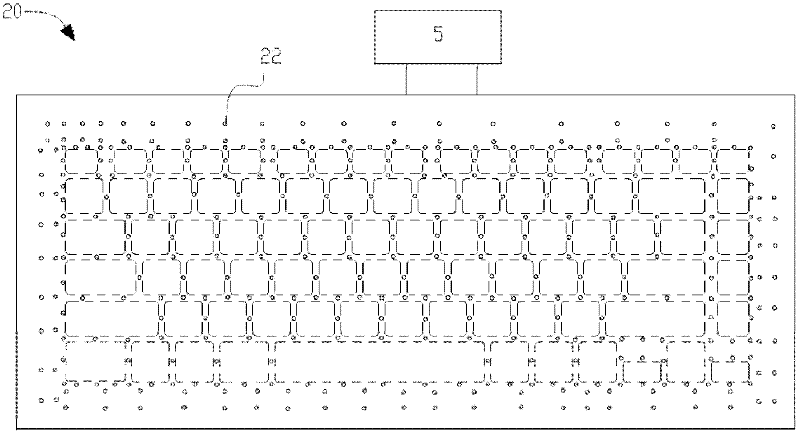

[0024] figure 2 It is a schematic structural view of the protective film 10 of the present invention, the protective film 10 is divided into a first area 31 and a second area 32, the second area 32 is arranged around the periphery of the first area 31, and the first area 31 and the second area There is a pre-break line 4 between the two regions 32 , and a release film (not shown) is attached to one side of the protective film 10 . The first region 31 and the second region 32 contain a plurality of connection points 41 at the pre-breaking line 4, the first region 31 and the second region 32 are connected through the connection points 41, wherein the width of the connection point The preferred choice is 0.05mm, the distance between adjacent connection points 41 is D, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com