Self-air-suction flotation machine impeller and self-suction flotation machine

A flotation machine, self-aspirating technology, applied in flotation, solid separation and other directions, can solve the problems of difficulty in improving the suction capacity, increased impeller wear, increased equipment energy consumption, etc., and achieves increased suction capacity and increased circulation capacity , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

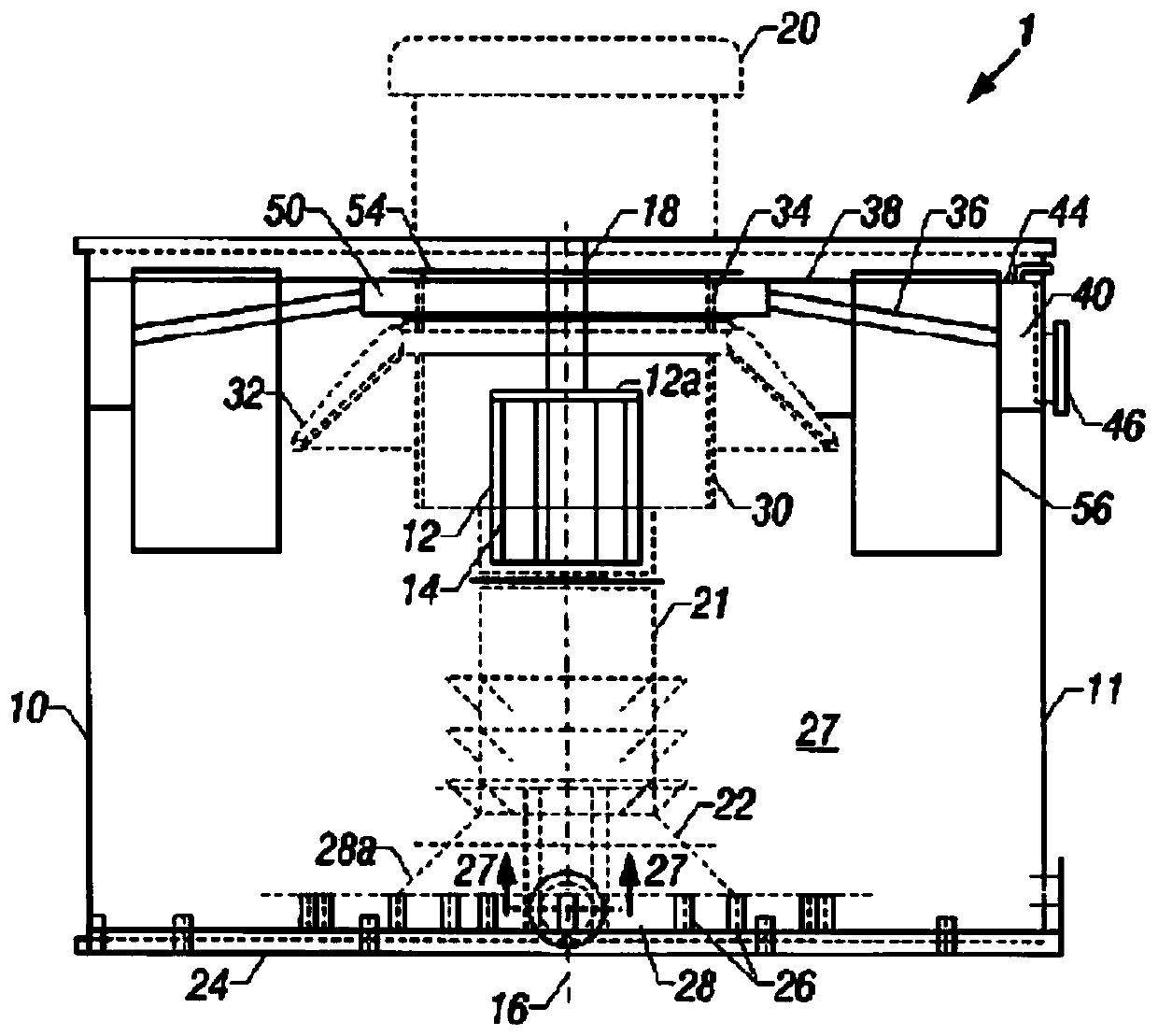

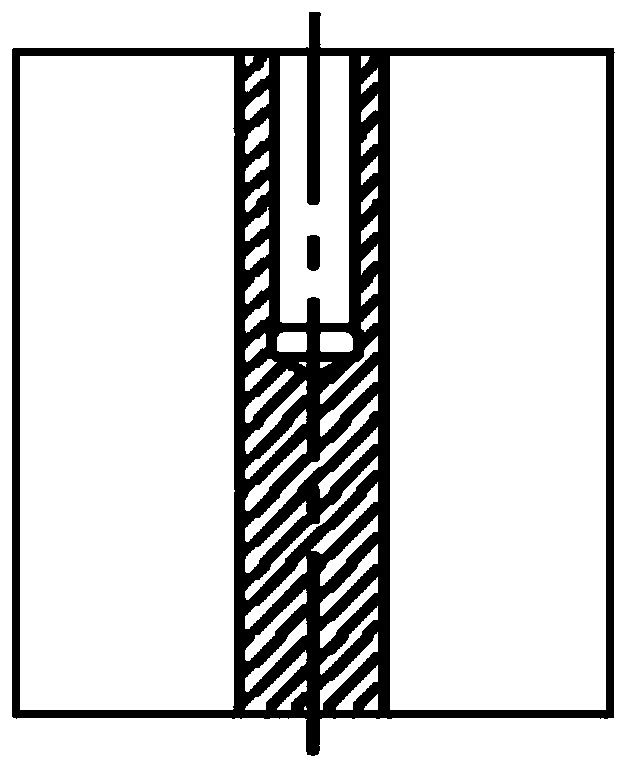

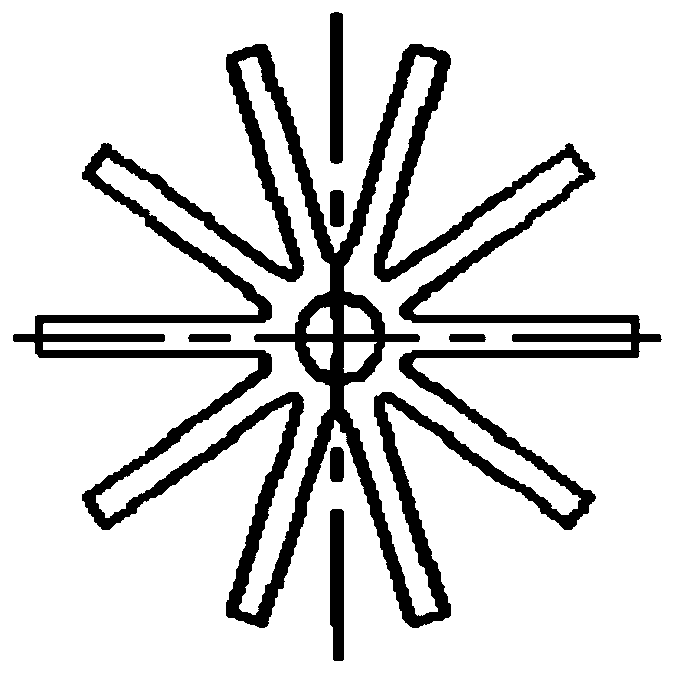

[0045] Such as Figure 4 Shown, a kind of impeller of self-suction flotation machine is used for self-suction flotation machine, and comprises central hub 9 and a plurality of blades 2, and blade 2 circumferential direction is uniformly fixed on the outer cylindrical surface along central hub 9, and central hub 9 The axial direction is arranged in parallel; the blade 2 is provided with a functional parameter influencing part to adjust the functional parameters of the blade; the functional parameters of the blade mainly include the suction volume of the flotation machine, the circulation volume of the ore pulp and the operating energy consumption. This example is mainly for the adjustment of the suction volume of the flotation machine, and the described functional parameter influencing part includes: the upper part of the axial longitudinal section of the blade 2 protrudes radially outwards with a suction volume influencing part 4, which is adjusted The suction capacity of the ...

Embodiment 2

[0051] Such as Figure 6 Shown, a kind of impeller of self-suction flotation machine is used for self-suction flotation machine, and comprises central hub 9 and a plurality of blades 2, and blade 2 circumferential direction is uniformly fixed on the outer cylindrical surface along central hub 9, and central hub 9 The axial direction is arranged in parallel; the blade 2 is provided with a functional parameter influencing part to adjust the functional parameters of the blade; the functional parameters of the blade mainly include the suction volume of the flotation machine, the circulation volume of the ore pulp and the operating energy consumption. This example is mainly aimed at the adjustment of the pulp circulation volume of the flotation machine. The functional parameter influencing part includes: the pulp circulation volume influencing part 5 protrudes radially outward from the lower part of the axial longitudinal section of the blade 2, Adjust the pulp circulation of the f...

Embodiment 3

[0057] Such as Figure 8 Shown, a kind of impeller of self-suction flotation machine is used for self-suction flotation machine, and comprises central hub 9 and a plurality of blades 2, and blade 2 circumferential direction is uniformly fixed on the outer cylindrical surface along central hub 9, and central hub 9 The axial direction is arranged in parallel; the blade 2 is provided with a functional parameter influencing part to adjust the functional parameters of the blade; the functional parameters of the blade mainly include the suction volume of the flotation machine, the circulation volume of the ore pulp and the operating energy consumption. This example is mainly aimed at the adjustment of the suction capacity of the flotation machine and the circulation volume of the ore pulp. The functional parameter influencing part includes: the upper part of the axial longitudinal section of the blade 2 protrudes radially outwards to have a suction capacity Affecting part 4, adjusts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com