Components of high-performance getter alloy and processing method of high-performance getter alloy

A processing method and high-performance technology, which are applied in the processing of high-performance getter alloys and the composition of high-performance getter alloys, can solve the problems of small inhalation capacity, low inhalation rate, and high activation temperature, and improve the inhalation process. Performance, suction capacity increase, effect of lowering activation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

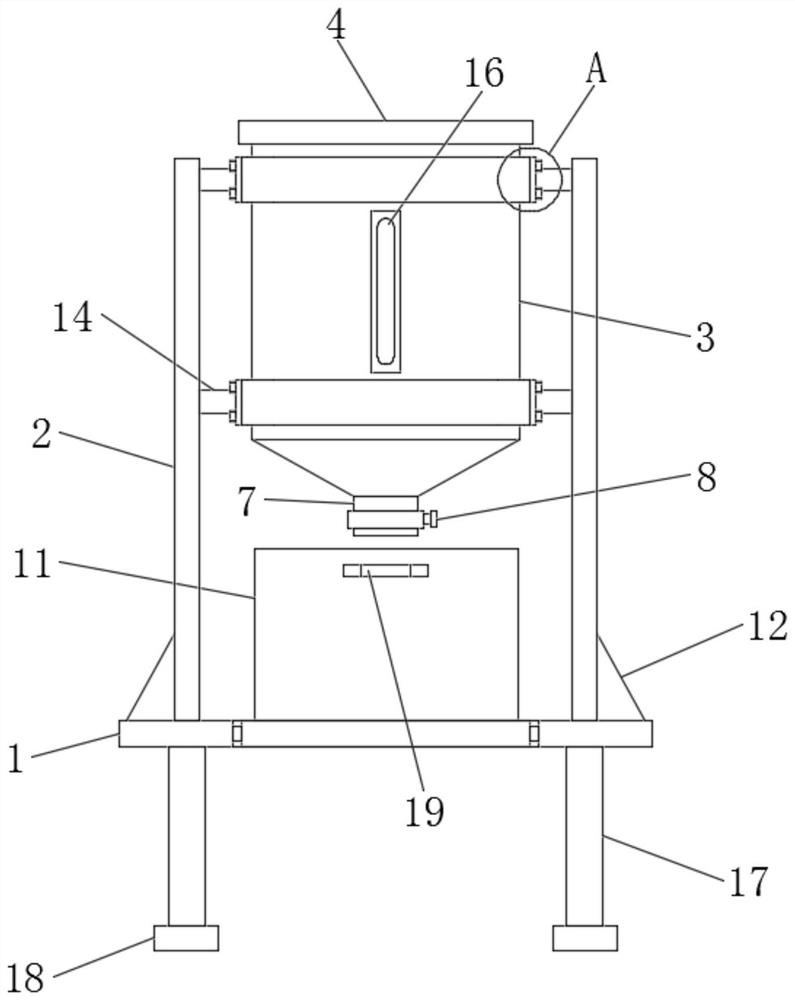

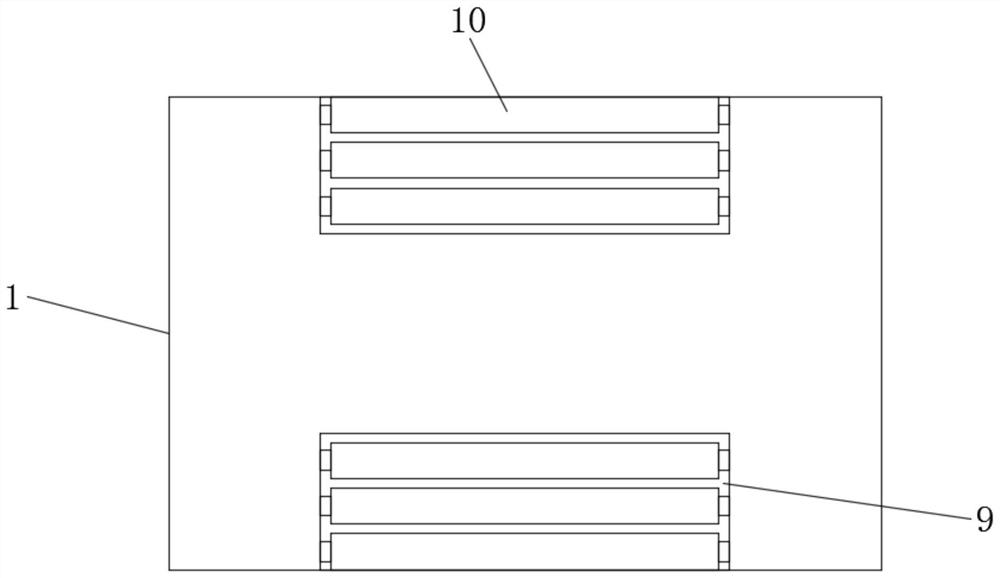

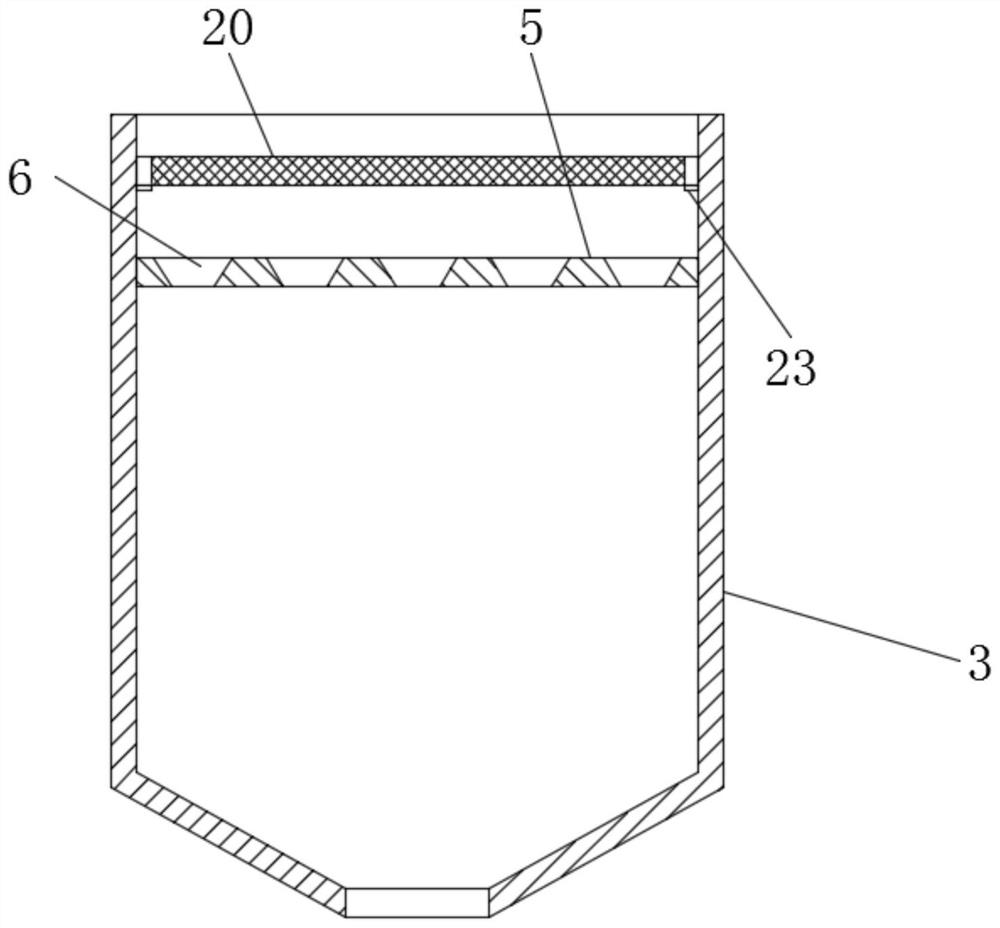

Image

Examples

Embodiment 1

[0044] The composition of a high-performance getter alloy, according to the mass components, the composition of the high-performance getter alloy is as follows:

[0045] The zircon content accounts for 60 parts, the material A content accounts for 15 parts, and the material B content accounts for 3 parts, among which, the zirconium purity in the zircon is greater than 95%;

[0046]Graphite content accounts for 25% in material A according to weight ratio, vanadium content accounts for 10%, niobium content accounts for 5%, and the balance is iron;

[0047] According to the weight ratio, the nickel content in the material B accounts for 15%, the chromium content accounts for 10%, the aluminum content accounts for 8%, the cobalt content accounts for 10%, and the balance is iron.

[0048] The invention also discloses a processing method of a high-performance getter alloy, which includes the following steps:

[0049] S1, select zircon, material A and material B raw materials accord...

Embodiment 2

[0064] The difference from Example 1 lies in the composition of a high-performance getter alloy. The composition of the high-performance getter alloy is as follows in terms of mass components:

[0065] The zircon content accounts for 60 parts, the material A content accounts for 15 parts, and the material B content accounts for 3 parts, among which, the zirconium purity in the zircon is greater than 95%;

[0066] Graphite content accounts for 25% in material A according to weight ratio, vanadium content accounts for 10%, niobium content accounts for 5%, and the balance is iron;

[0067] According to the weight ratio, the nickel content in the material B accounts for 15%, the chromium content accounts for 10%, the aluminum content accounts for 8%, the cobalt content accounts for 10%, and the balance is iron.

[0068] The invention also discloses a processing method of a high-performance getter alloy, which includes the following steps:

[0069] S1, select zircon, material A an...

Embodiment 3

[0076] The difference from Example 1 lies in the composition of a high-performance getter alloy. The composition of the high-performance getter alloy is as follows in terms of mass components:

[0077] Zircon content accounts for 80 parts, material A content accounts for 18 parts, material B content accounts for 6 parts, and the zirconium purity in zircon is greater than 95;

[0078] According to the weight ratio, graphite content accounts for 30% in material A, vanadium content accounts for 5%, niobium content accounts for 1%, and the balance is iron;

[0079] According to the weight ratio, the nickel content in the material B accounts for 20%, the chromium content accounts for 6%, the aluminum content accounts for 3%, the cobalt content accounts for 15%, and the balance is iron.

[0080] The invention also discloses a processing method of a high-performance getter alloy, which includes the following steps:

[0081] S1, select zircon, material A and material B raw materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com