Integrated type rear-mounted guide wheel rope discharge and rope storage friction winch

An integrated, rope-arranging technology, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of large footprint and separation, and achieve the effects of light weight, reduced lateral force, and increased distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

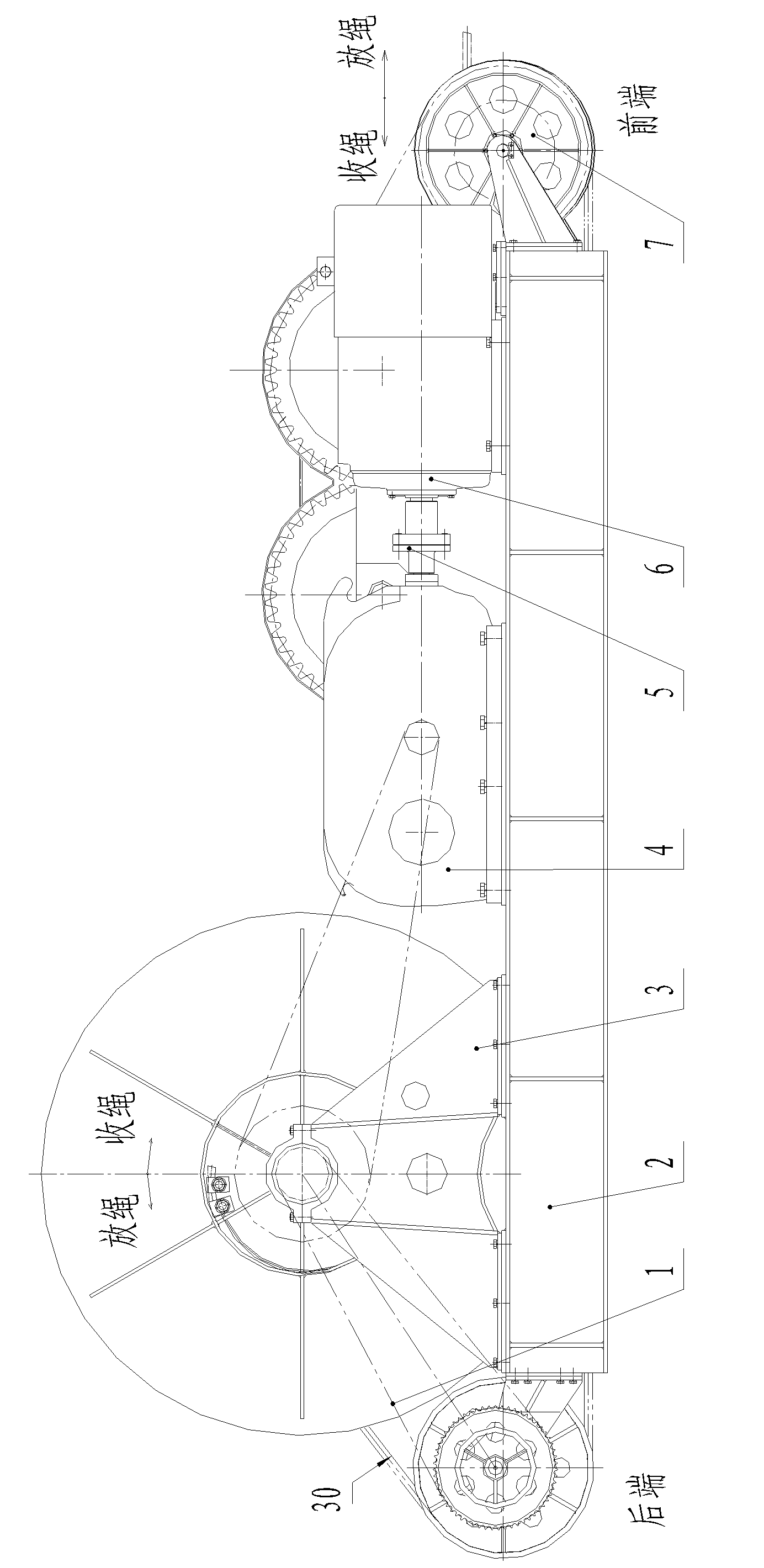

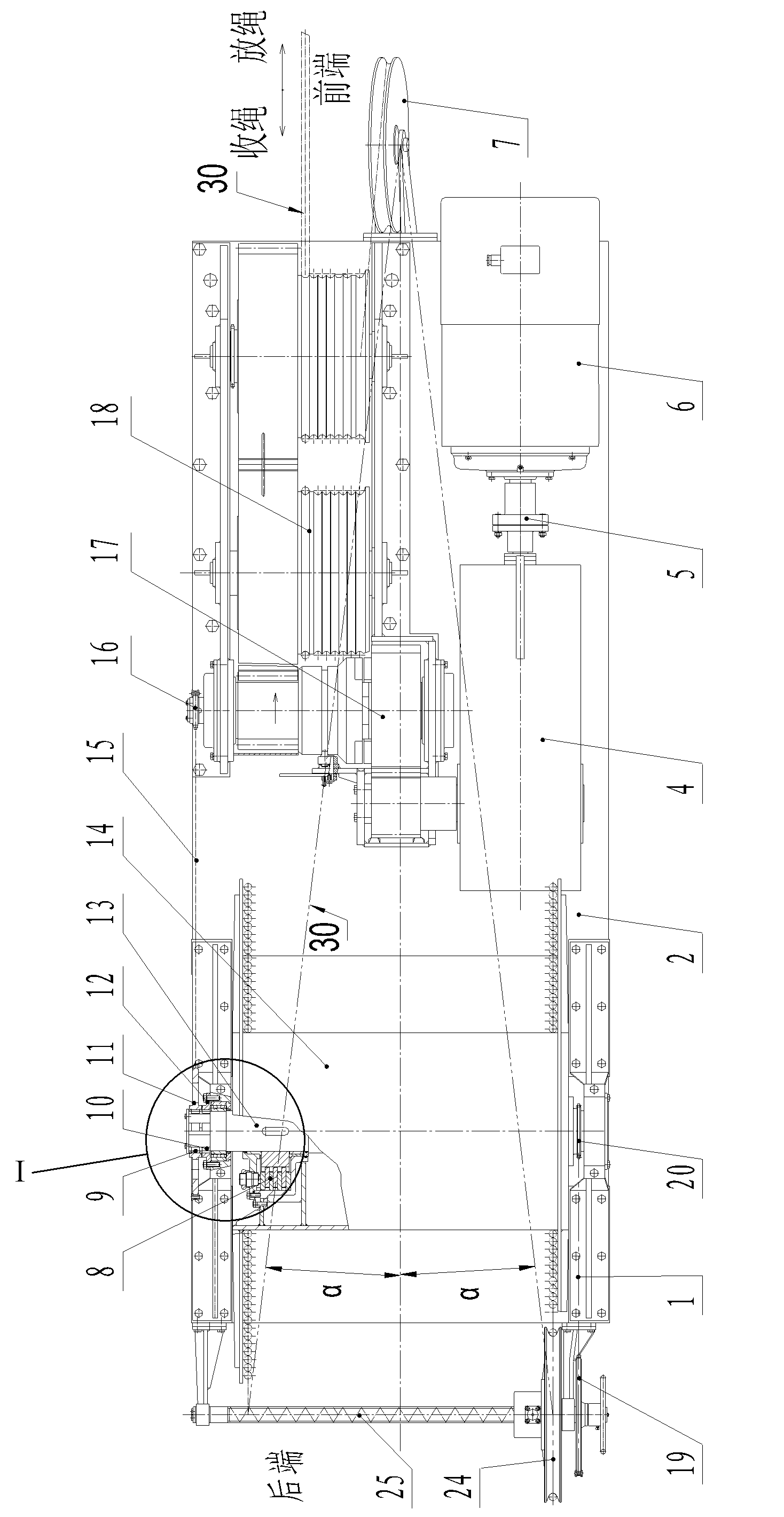

[0031] Such as figure 2 As shown, the integrated rear guide wheel rope storage rope friction winch of the present invention includes a winch rope 30 and a motor 6 fixed on a base 2, a reducer 4, a main drum transmission mechanism 17, a main drum 18, and a rope storage drum device and pulley rope arrangement, such as figure 1 As shown, the motor 6 is connected to the speed reducer 4 through a shaft coupling 5, and transmits power to the rope storage drum device through the main drum transmission mechanism 17 and a rope storage drum driving sprocket transmission mechanism.

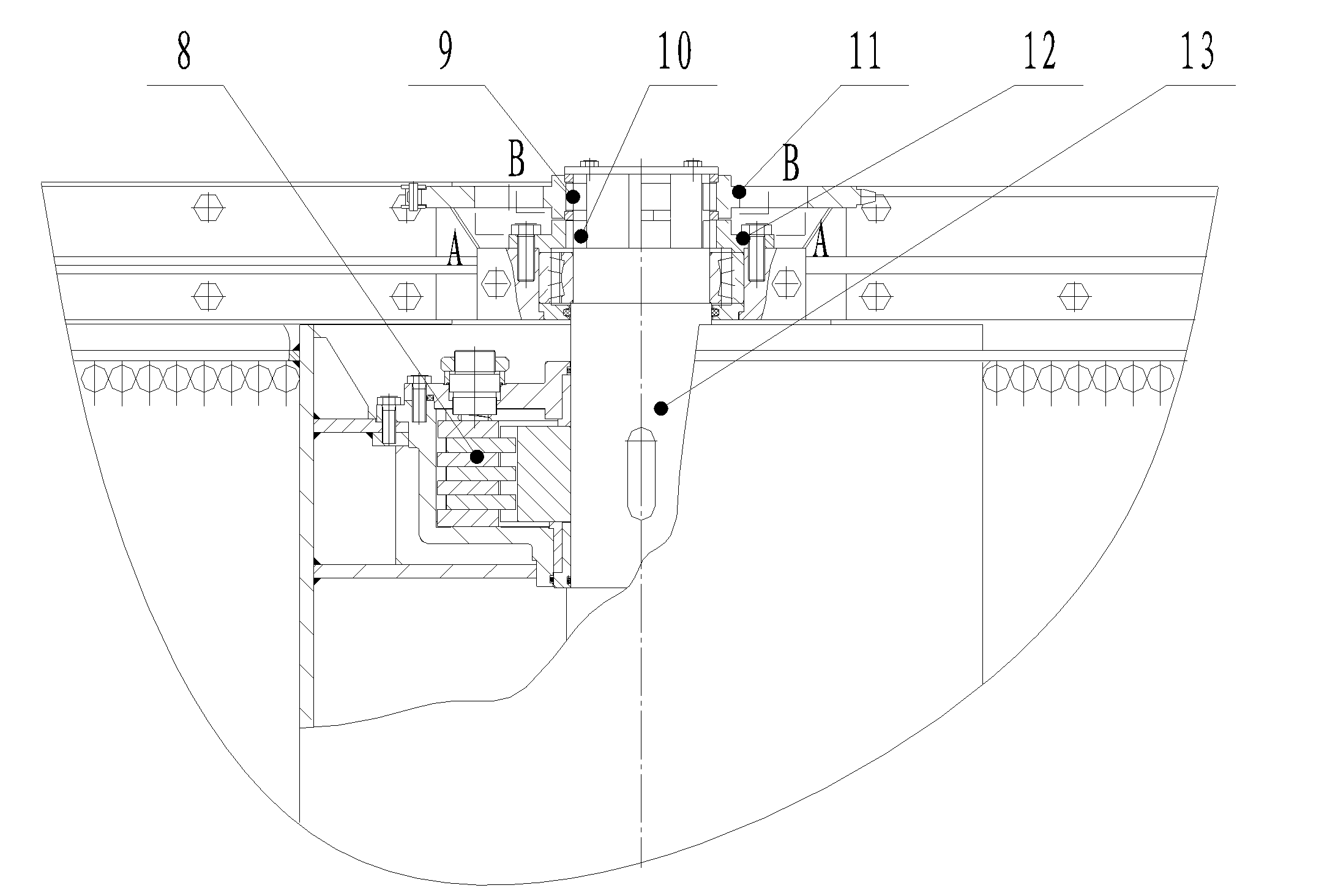

[0032] Such as figure 2 As shown, the rope storage drum device includes a rope storage drum main shaft 13 connected with the above-mentioned rope storage drum sprocket transmission mechanism, and the rope storage drum main shaft 13 drives a rope storage drum 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com