A four-link hub motor trailing arm suspension

An in-wheel motor and trailing arm technology, applied in the field of vehicle engineering, can solve the problems of insufficient longitudinal flexibility of the suspension, heavy weight of the independent suspension, large lateral stiffness, etc., so as to improve the steering and braking performance and improve the safety of the vehicle. , the effect of large suspension lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

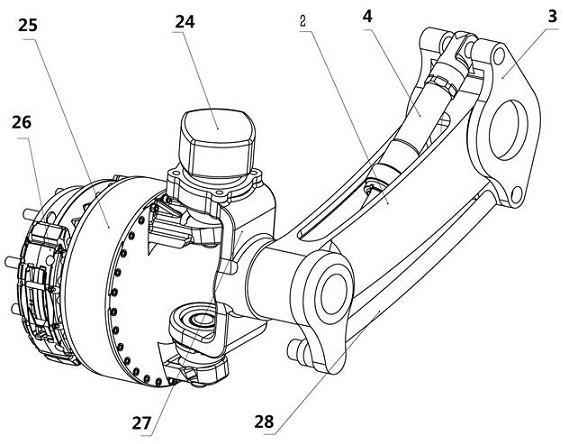

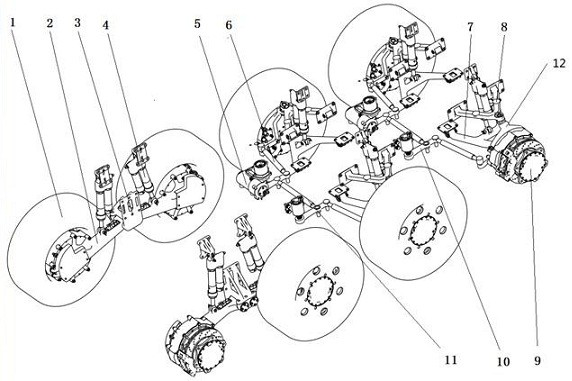

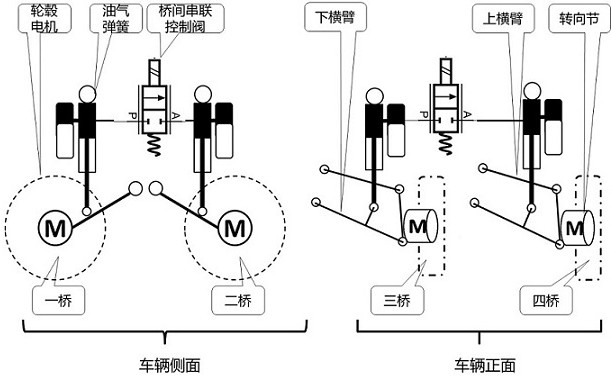

[0038] Such as figure 1 and 2 As shown, a four-link hub motor trailing arm suspension includes a trailing arm mounting bracket 3, a trailing arm 2, an oil-pneumatic spring 4, a steering motor 24, a hub motor 25, a brake 26, a steering knuckle 27, and a connecting rod 28. Screw holes are reserved on the longitudinal arm mounting bracket 3 for installation on the vehicle body; the longitudinal arm 2 is of thin-walled structure with a wall thickness of 5mm, and its pin shaft end is coupled with the mounting bracket 3 to form a rotary pair to realize longitudinal The arm swings around the car body; the trailing arm adopts a hollow structure, which not only reduces the weight of the suspension system, but also facilitates the lowering of the shock absorber to the point installation position, reducing the occupation of the longitudinal space of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com