A steering knuckle connector assembly suitable for linear translation front suspension

A steering knuckle and translational technology, which is applied in the direction of steering mechanism, steering rod, vehicle components, etc., can solve the problems that the hub unit of the suspension mechanism cannot be connected smoothly, the steering knuckle does not have the steering function, and the front suspension system is not applicable. , to achieve the effect of flexible suspension layout, strong designability and improved handling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings and embodiments:

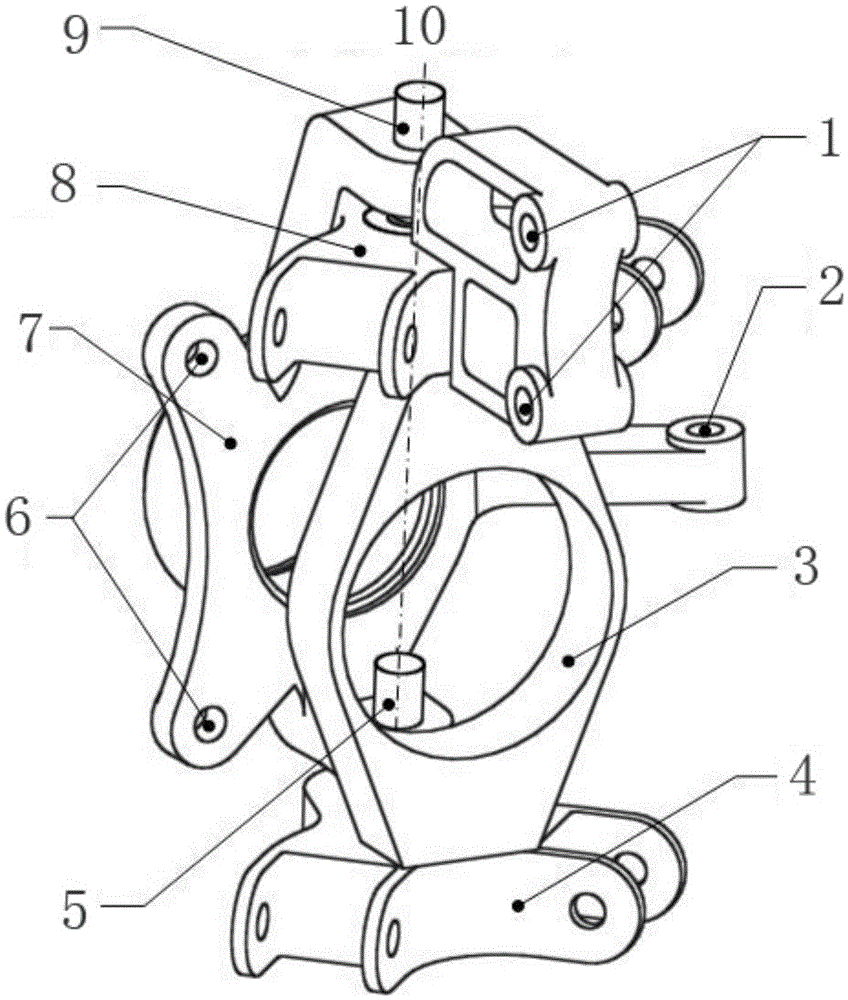

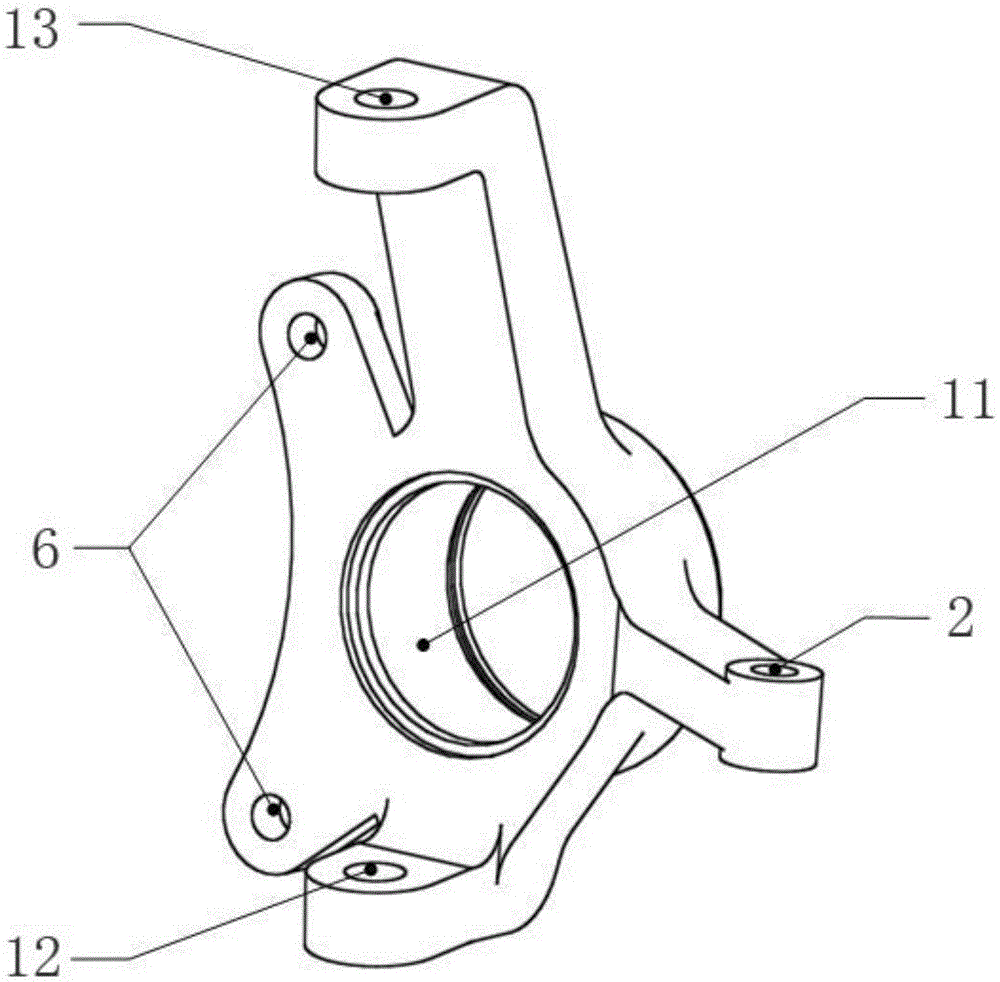

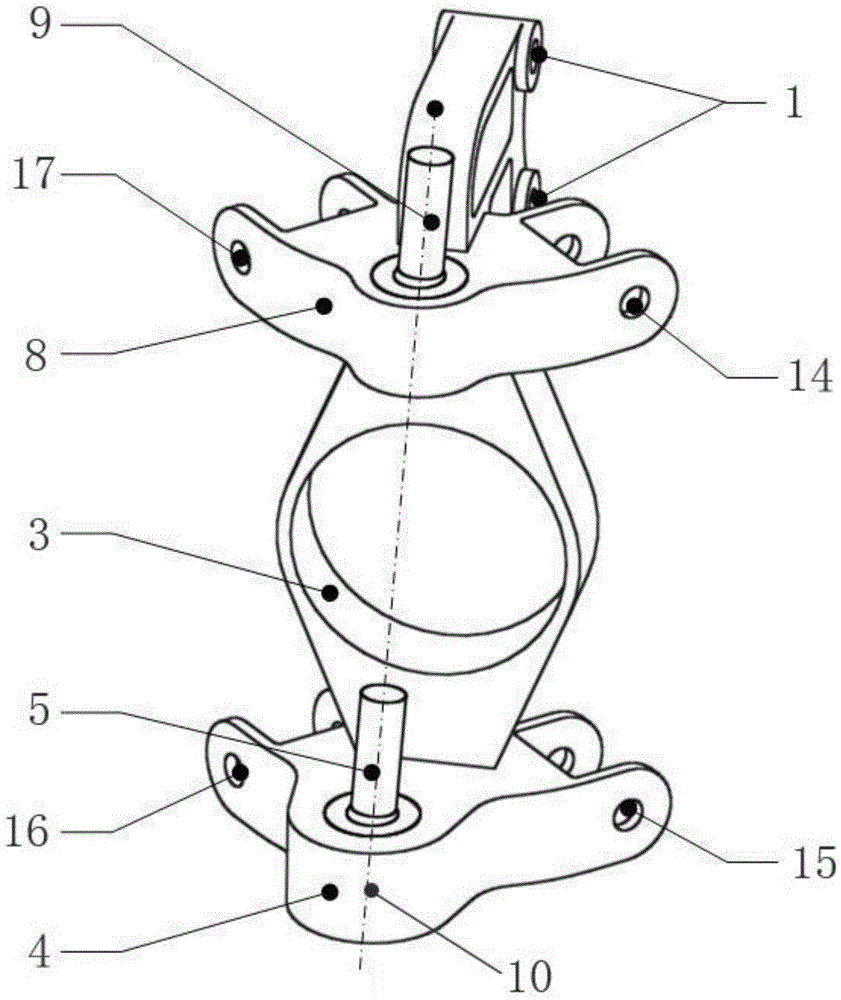

[0014] Such as Figure 1-3 As shown, this kind of steering knuckle connector assembly suitable for linear translational front suspension mainly includes a steering knuckle body 7, an upper ball stud 9 and a lower ball stud 5, and an upper base 8 connected by a suspension branch chain. The lower base 4 and the reinforcement 3, the upper base 8 and the lower base 4 are fixedly connected by the reinforcement 3, and the reinforcement 3 is provided with a through hole for arranging the drive shaft 103 to pass through, avoiding structural and movement interference . The steering knuckle 7 is provided with a brake mounting hole 6 for assembly with the brake 105, a steering rod mounting hole for assembly with the steering tie rod 104, a hub bearing unit assembly hole 11 for assembly with the hub unit, and assembly with the lower ball pin 5. The lower end ball head mounting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com