Electrowetting display device and display method

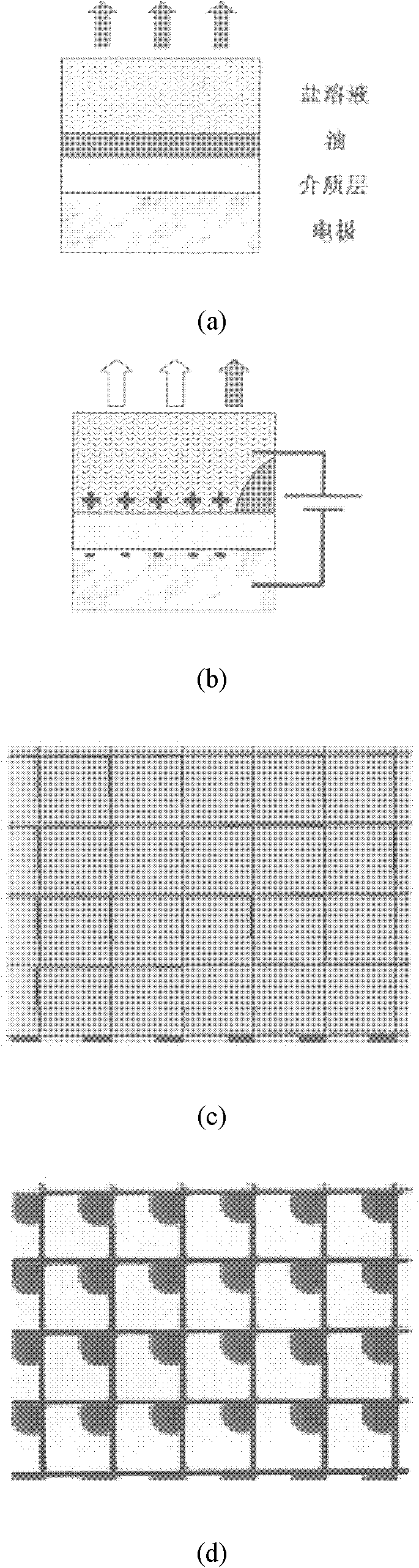

An electrowetting display and electrode technology, which is applied in static indicators, instruments, nonlinear optics, etc., can solve the problem of unable to achieve color display effect, and achieve the effect of realizing full color display and saving response time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Such as figure 2 As shown, the display device of this embodiment includes an ink accommodating cavity, and the ink accommodating cavity is filled with inks of different colors, and the inks of different colors are incompatible with each other and are not soluble in the solution. The ink accommodating cavity is composed of an outer shell and an inner shell embedded in the outer shell. Both the outer shell and the inner shell are closed structures, and the ink is located in the cavity formed between the outer shell and the inner shell. The shapes of the outer shell and the inner shell are both cuboids. At this time, the ink holding cavity is divided into six cavities: upper, lower, left, right, front, and rear, and the six cavities are filled with different colors. ink.

[0031] The upper, lower, left, right, front and rear six cavities of the ink holding cavity are used to fill inks of different colors (the upper cavity is the display layer of the display device), so t...

Embodiment 2

[0036] Regarding the display device, it is conceivable that the upper cavity is the display surface, and the ink in the four cavities, front, rear, left, and right adjacent to the upper cavity can enter the display surface immediately when displayed, but the ink in the lower cavity needs to transition to a cavity in the middle. access to the display surface, which may adversely affect response time. Therefore, this embodiment is improved.

[0037] Such as Figure 5 As shown, a pipe communicating with the upper and lower cavities is set between the upper and lower cavities, so that the ink in the lower cavity can directly enter the upper cavity for display in one step without passing through the transition between the left and right cavities, thereby saving Response time.

Embodiment 3

[0039] In order to save response time, the lower cavity of this embodiment does not store ink, so that one pixel can display five colors at different times.

[0040] The types of colors that can be displayed by a pixel are determined by the amount of ink in the display device. Therefore, two or four colors can also be displayed. The display principle is similar to the six-color display in Embodiments 1 and 2.

[0041] Due to the incompatibility between the inks, each pixel of the present invention can also display the mixed colors of the inks, that is, two or more inks enter the display layer at the same time, for example, half of the red ink and the other half of the yellow ink can be realized. display, or 1 / 3 red ink, 2 / 3 yellow ink display. Monochrome display means that one pixel can realize one color at the same time, and two-color display is a mixed color of two colors at one pixel at the same time, and three or four colors can also be mixed. However, when applied to a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com