Sealing ring, in particular for a hydraulic piston pump

A hydraulic piston pump and sealing ring technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as damage and leakage of sealing components, and achieve the effect of small leakage, avoiding functional damage and small wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

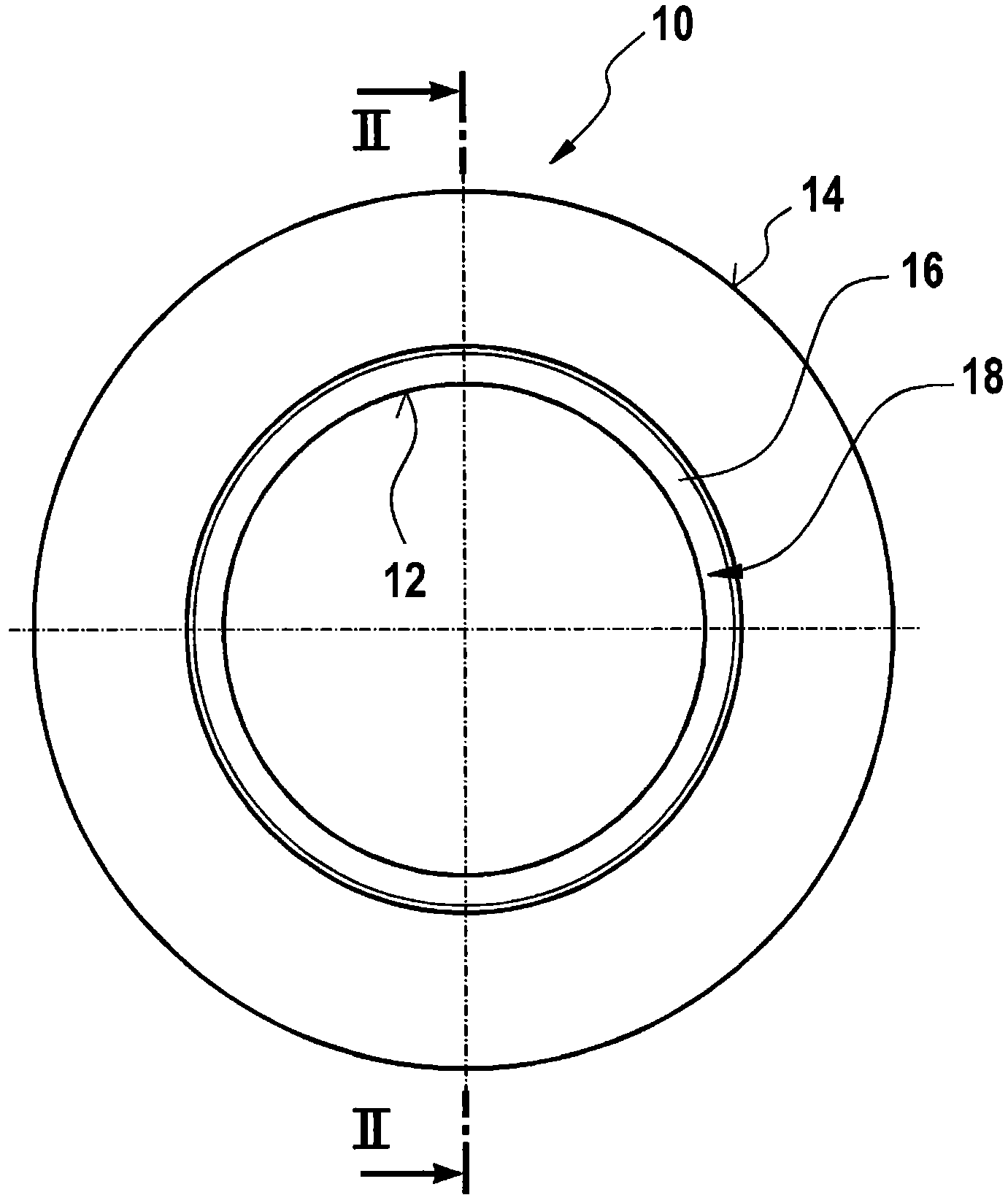

[0053] figure 1 A sealing ring 10 according to the invention is shown having an inner peripheral surface 12 and an outer peripheral surface 14 . On the inner peripheral surface 12, the sealing ring 10 has a sealing lip 16 with a defined contour 18 (see figure 2 ).

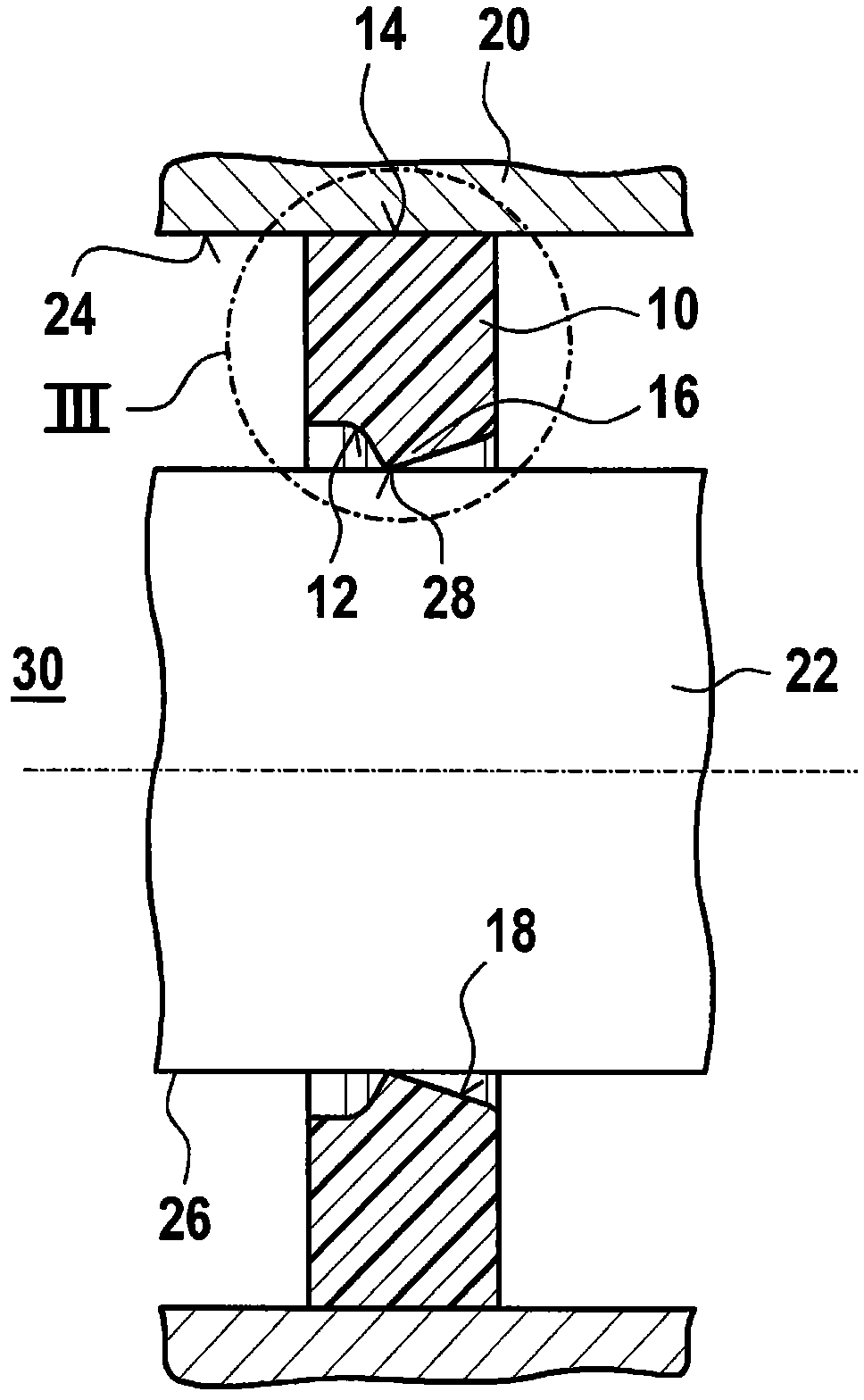

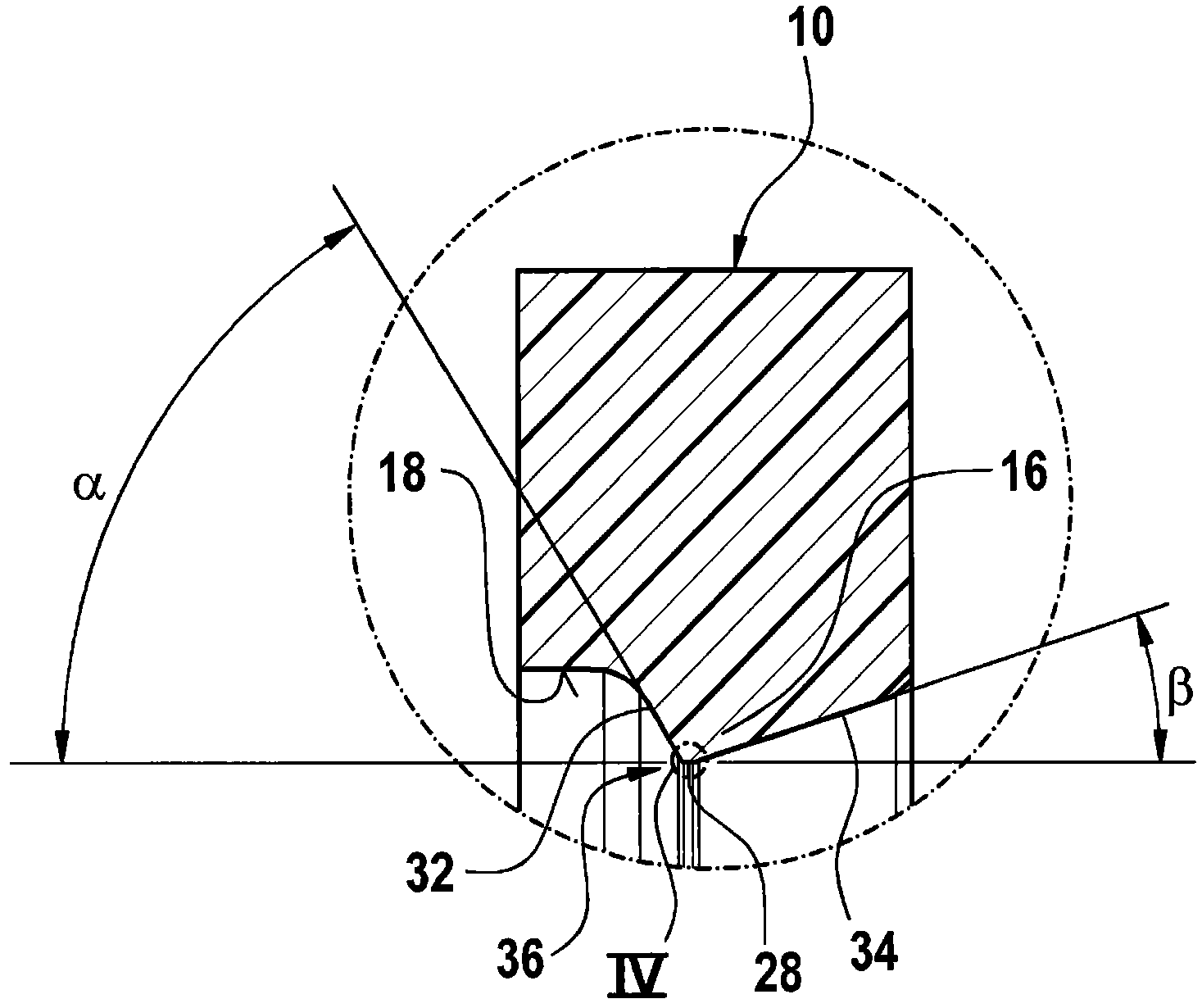

[0054] figure 2 Shown is a sealing ring 10 which is arranged between a cylindrical wall 20 of a cylindrical chamber and a piston 22 of a hydraulic piston pump. The sealing ring 10 bears with its outer peripheral surface 14 against the inner peripheral surface 24 of the cylindrical wall 20 and with the defined contour 18 of the sealing lip 16 against the outer peripheral surface 26 of the piston 22 . The piston 22 is configured to move in and out inside the cylindrical chamber and forms a sealing surface 28 on the contact surface between the sealing lip 16 and its outer peripheral surface 26 , which is opposite to the sealing lip 16 of the sealing ring 10 Movable. The sealing ring 10 here seals off the fluid-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com