Strapping leveler

The technology of a leveling machine and a frame is applied in the field of steel strapping and packaging, which can solve the problems of low operation efficiency and large labor volume, and achieve the effects of simple operation, high degree of automation, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

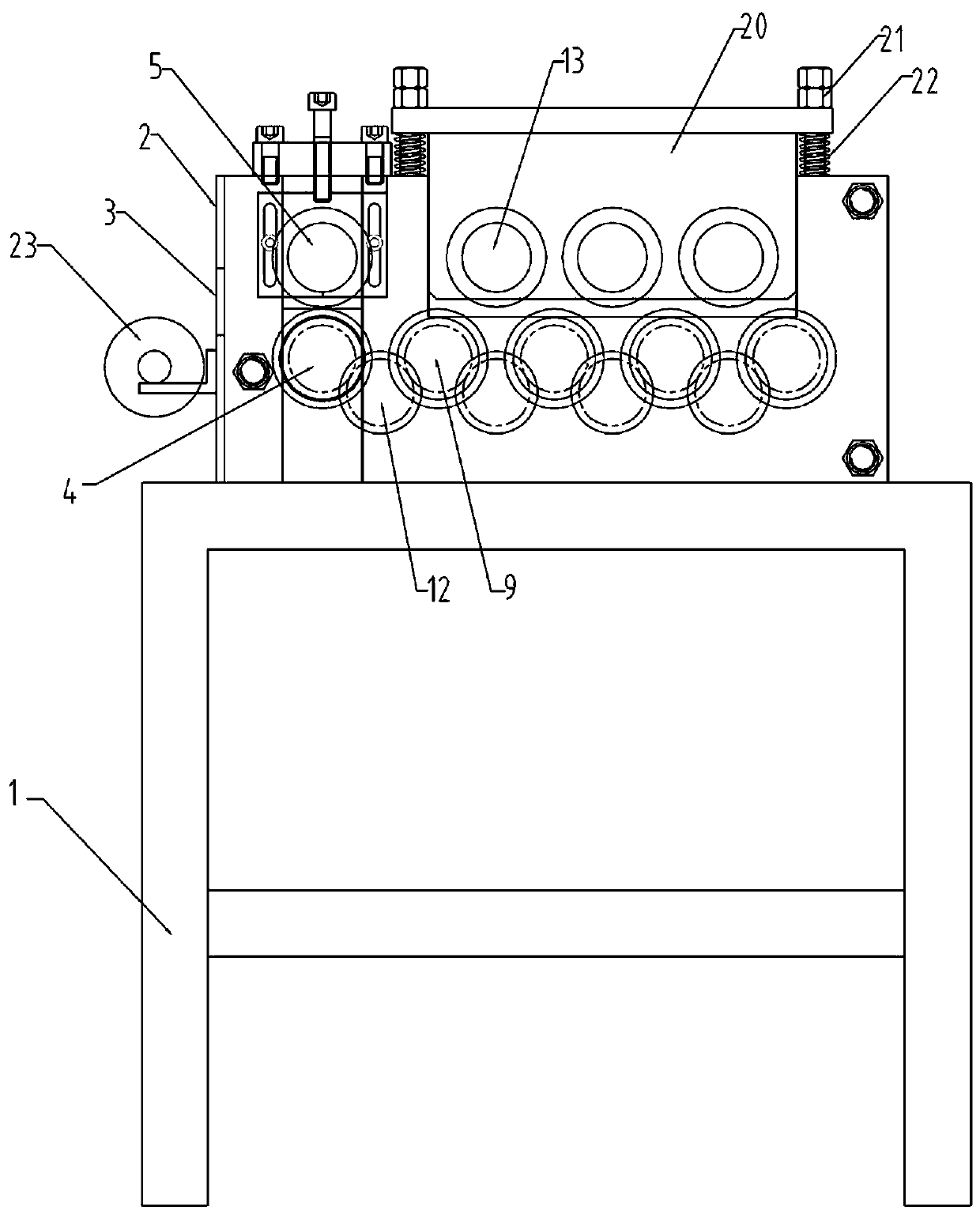

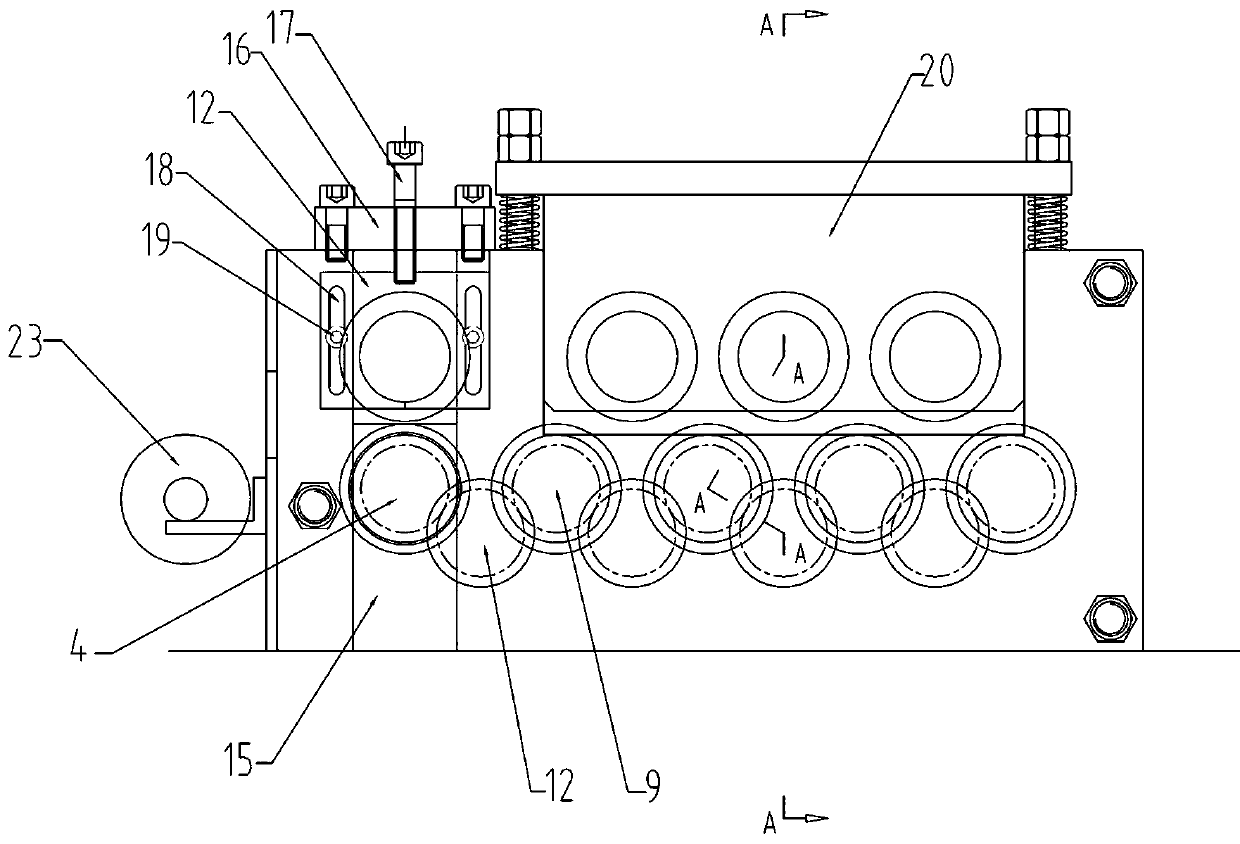

[0030] Embodiment 1: a kind of strap straightening machine, see Figure 1-Figure 5 , including a frame 1, a protective plate 2 is provided at the front end of the frame 1, and a strap feeding port 3 is provided on the protective plate 2.

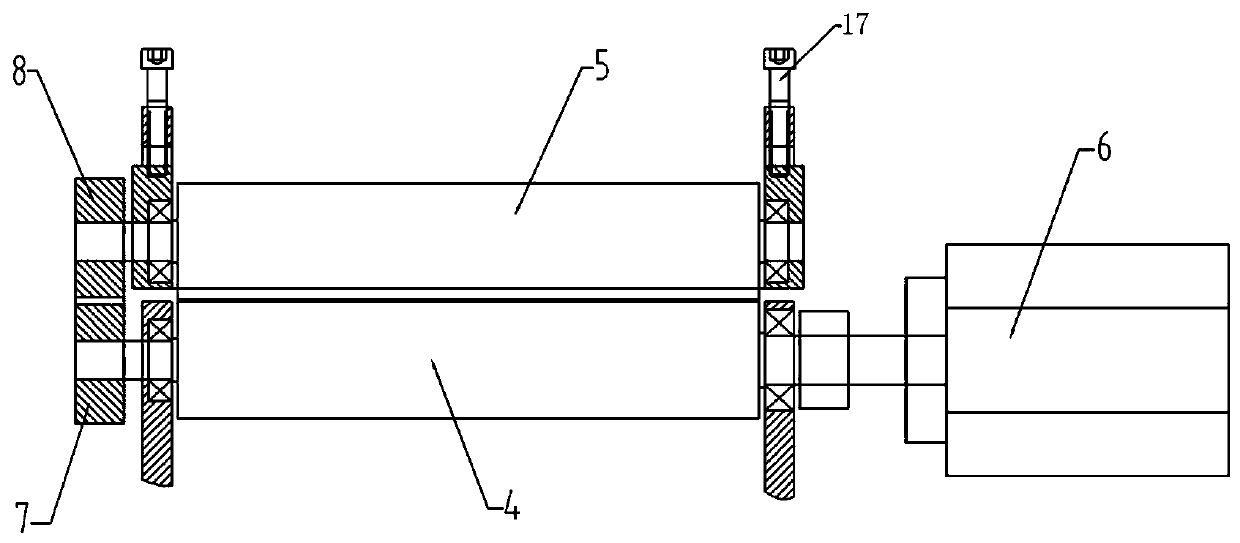

[0031] The inner side of the strap feeding port 3 is provided with a lower nip roller 4 and an upper nip roller 5 corresponding to the upper and lower positions. The lower nip roller 4 is fixedly connected with the frame 1 through a bearing. The corresponding output shafts of the lower pinch rollers 4 are connected, the other end of the lower nip roller 4 is provided with a coaxial lower gear 7, and the corresponding end of the upper nip roller 5 is provided with a coaxial upper gear 8, and the lower gear 7 is meshed with the upper gear 8, see image 3 shown.

[0032] On the frame 1 and at the same horizontal position as the lower nip roller 4, a transmission roller 9 is arranged, and at the end where the lower nip roller 4 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com