Welding backing of CO2 vertical electrogas automatic one-side welding, and method for using same

A welding backing and single-side welding technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve the effects of improving weld quality, saving welding materials, and reducing welding processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]

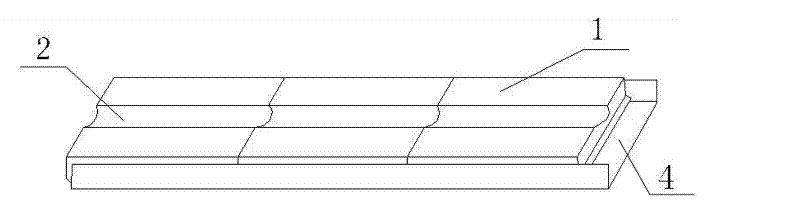

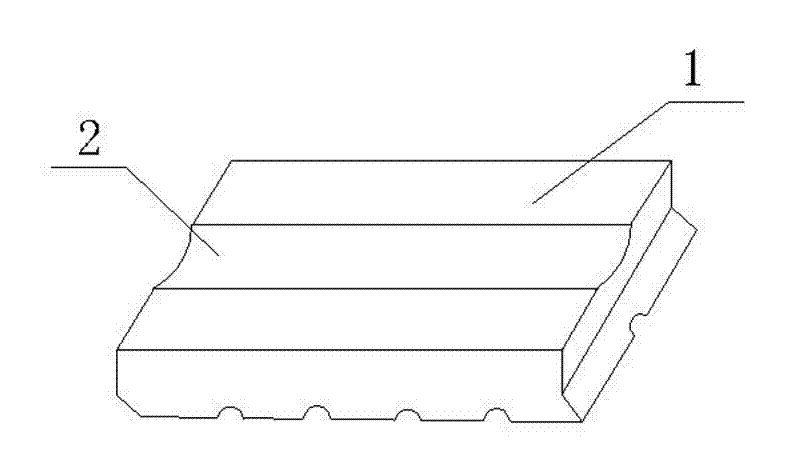

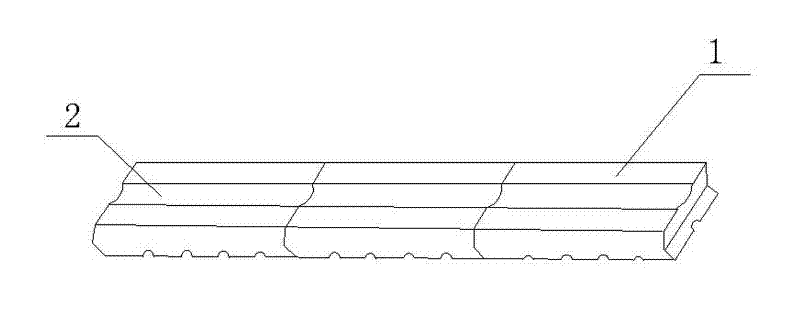

[0015] The present invention is CO 2 Ceramic welding backing for vertical gas-electric automatic single-sided welding. The pad includes at least one ceramic welding pad block, and the front side of the pad block is provided with a weld seam forming groove.

[0016] The liner includes one or several liner blocks, and the raw material composition of the liner block includes: alumina, quartz, talc, feldspar, china clay, Suzhou black soil, white mud and titanium dioxide, and the weight ratio of the above raw materials is : Bauxite: 20~40; Quartz: 10~20; Talc: 10~15; Feldspar: 5~10; China clay: 2~16; Suzhou black soil: 10~20; 3~5.

[0017] After the above raw materials are mixed, CO is produced through a special manufacturing process. 2 Welding backing block for vertical gas-electric automatic single-sided welding.

[0018] The liner block of the recipe is in CO 2 In the welding metallurgical process of vertical gas-electric single-sided automatic welding, the slag i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com