Device capable of automatically diagnosing and correcting divergence angle and beam quality of laser beam

A technology of laser beam and beam quality, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of automatic measurement and control technology, difficult to achieve ideal beam quality of high-power lasers, and large focal spot size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

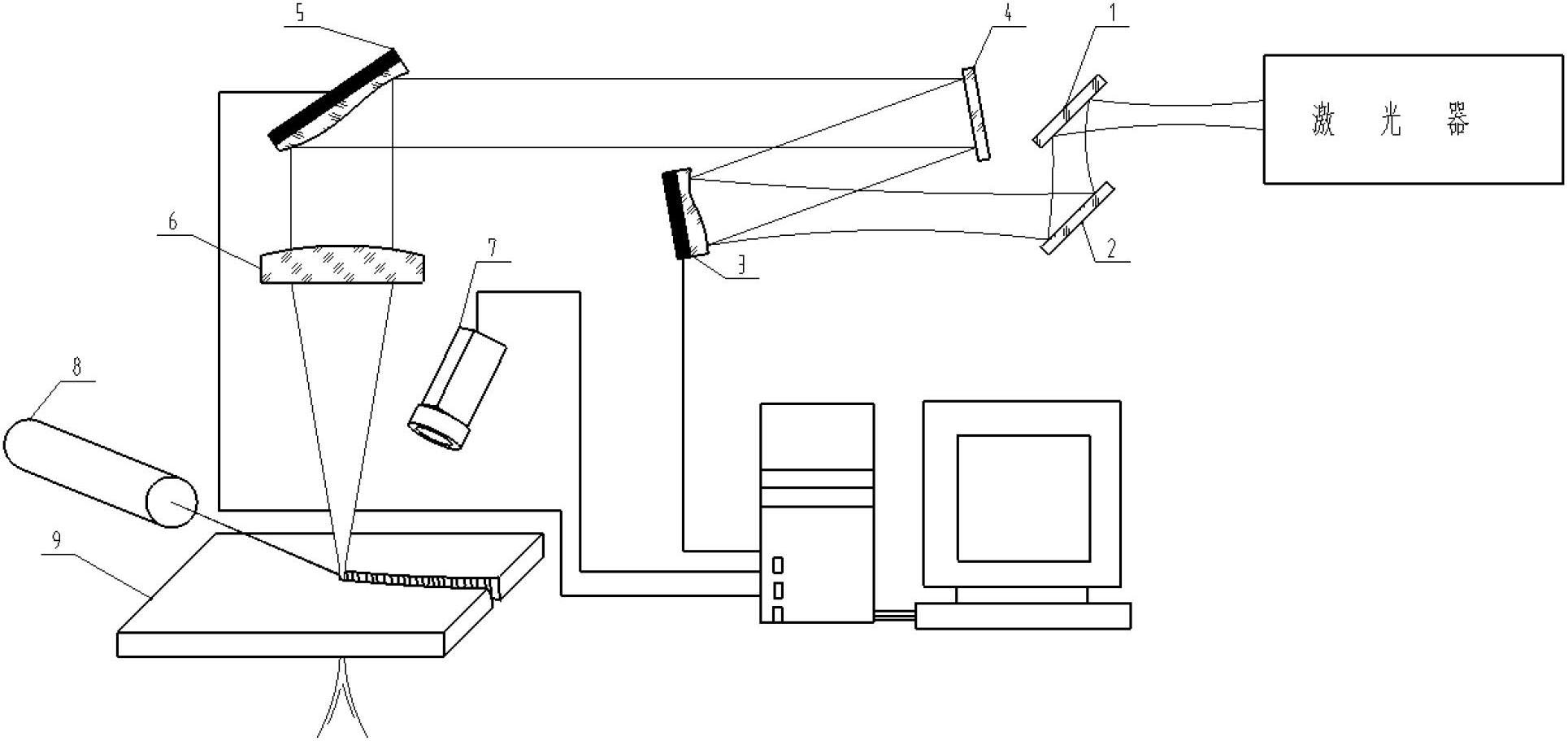

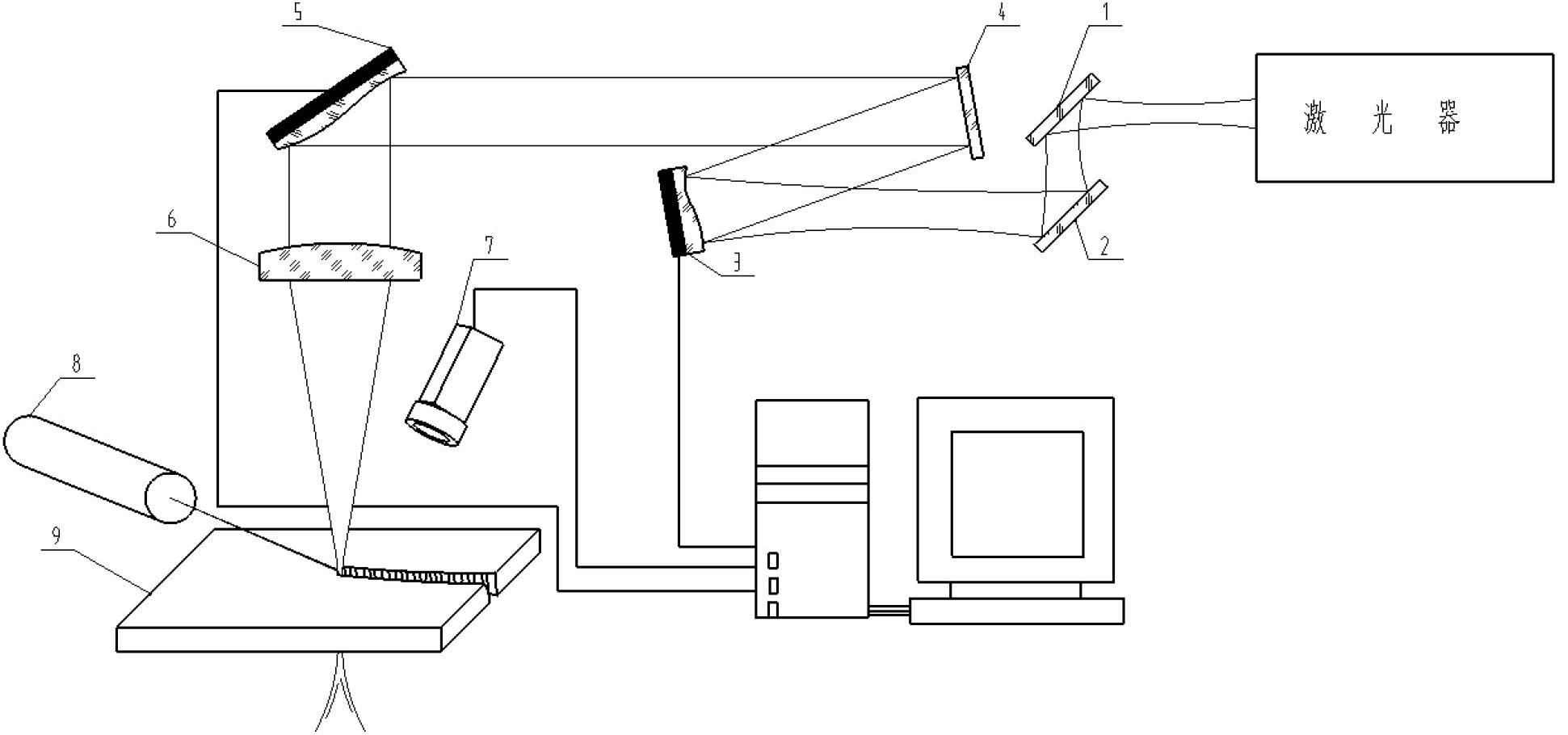

[0012] Such as figure 1 As shown, adjust the optical parts so that the beam output by the laser is reflected by the first auxiliary reflector 1, the second auxiliary reflector 2, the first deformable mirror 3, the third auxiliary reflector 4, and the second deformable mirror 5. The workpiece 9 is cut through the focusing lens 6, and the laser cutting information is recorded by the CCD. The arc light generated during the processing will submerge the image signal. At this time, the auxiliary light source 8 can be used to illuminate the workpiece: the auxiliary light source 8 can be a wide-spectrum LED light source, and a narrow-band filter is placed in front of the diagnostic device 7. Stray light rays such as arc light reflected on the 9 can be filtered out when entering the diagnostic device 7 . According to the incision information picture obtained by multiple records, the computer calculates the width (or depth) of the incision. The calculation method of the incision width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com