Error-proofing clamp for press-mounting wind wheel

An error-proofing and wind-wheel technology, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of easy installation errors and low efficiency of press-fitting wind rotors, so as to reduce work intensity, broad market application prospects, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

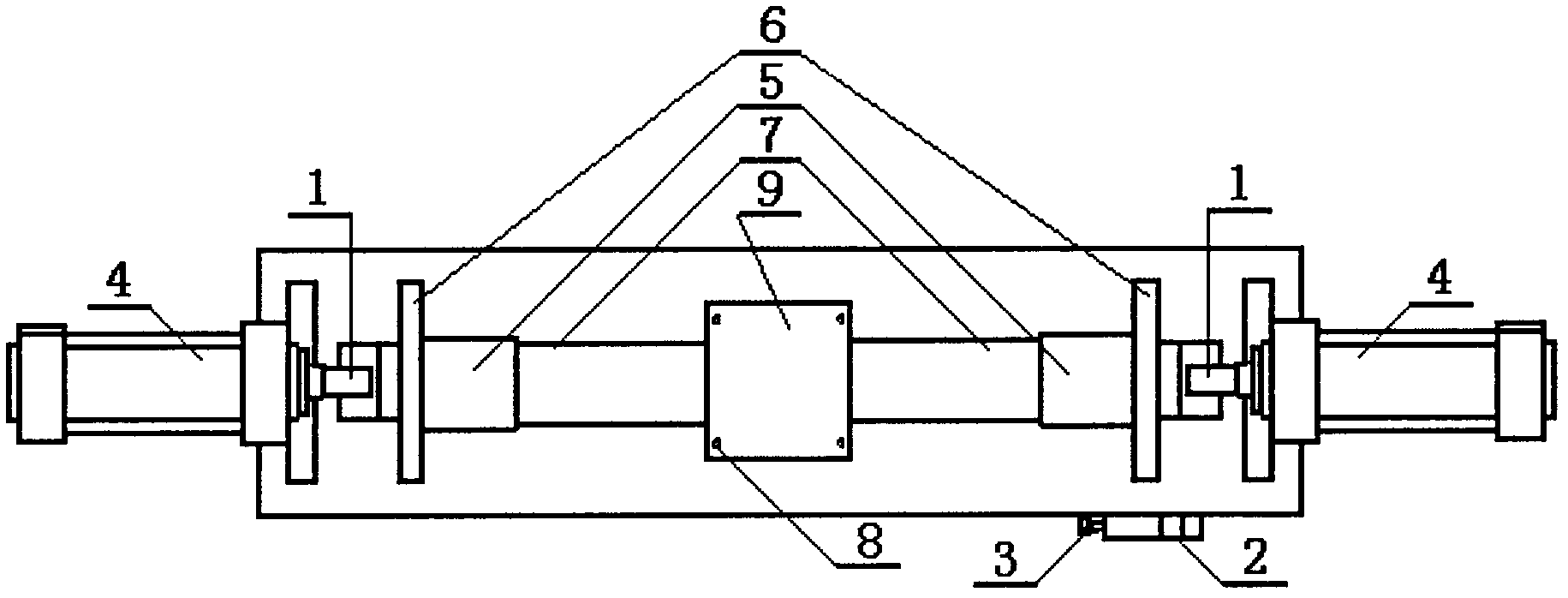

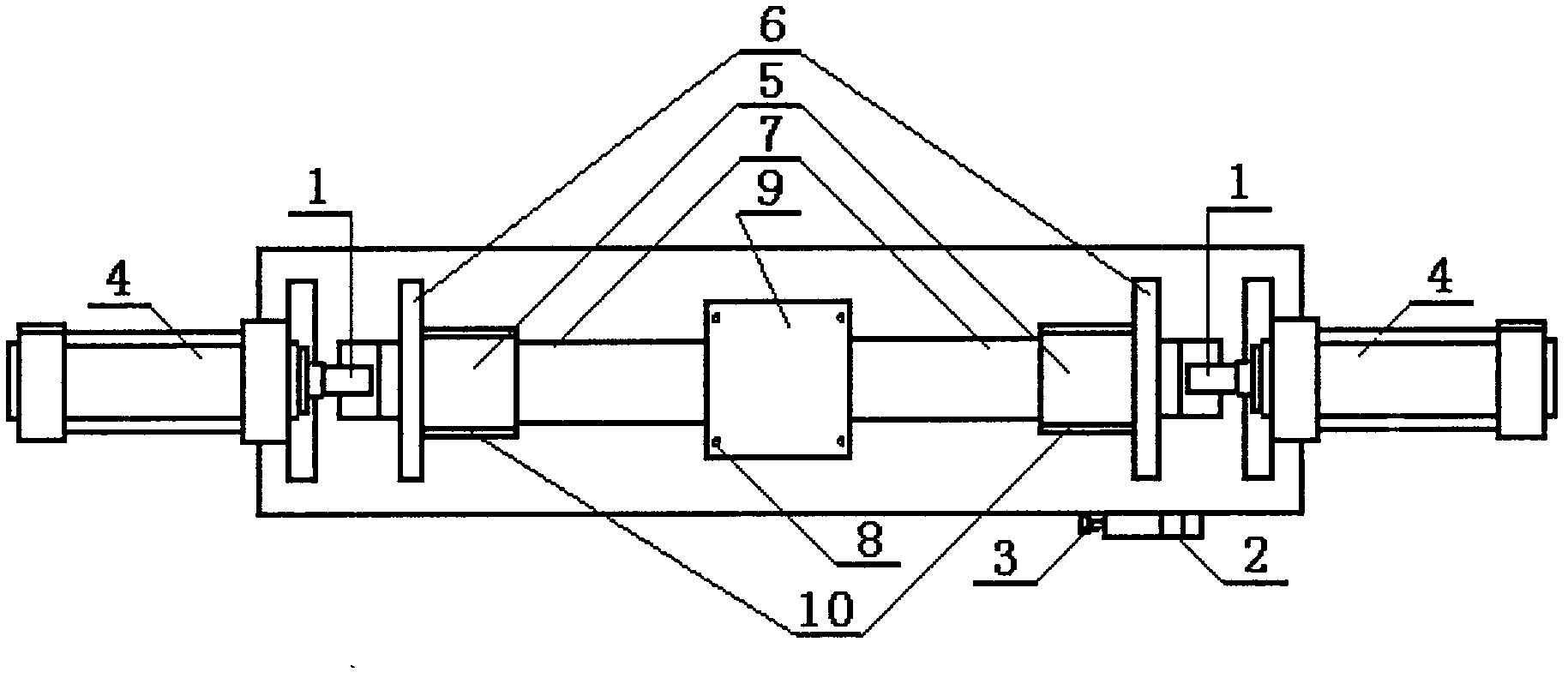

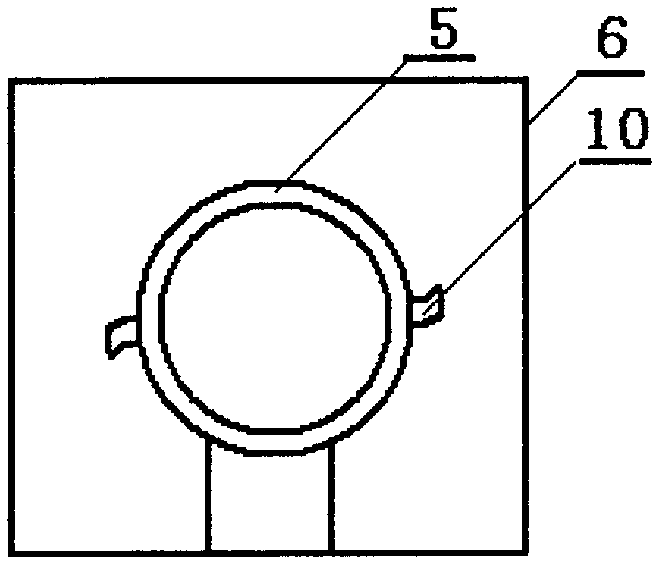

[0013] exist figure 1 , figure 2 and image 3 Among them, the wind wheel press-fit error-proof fixture of the present invention is mainly controlled by the solenoid valve 2 and the control handle 3, the left and right cylinders 4 with the push rod 1 on the top, the left and right push blocks 6 with the guide cylinder 5 on the top, and the The left and right guide rails 7 on which the push block 6 slides and the middle base plate 9 with the positioning post 8 for the upper band limit motor constitute. The feature is that the outer surface of the guide cylinder 5 of the push block 6 is axially increased and symmetrically provided with two anti-error convex wings whose shape and size are consistent with the shape and size of the gap between two adjacent blades on the wind wheel. 10.

[0014] When working, the motor is fixedly positioned on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com