Piston pump cylinder cup assembly device and assembly method

An assembly device and plunger pump technology, which is applied in the field of auto parts, can solve problems such as flanging and edge warping, and achieve the effects of high pass rate, simple and convenient operation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

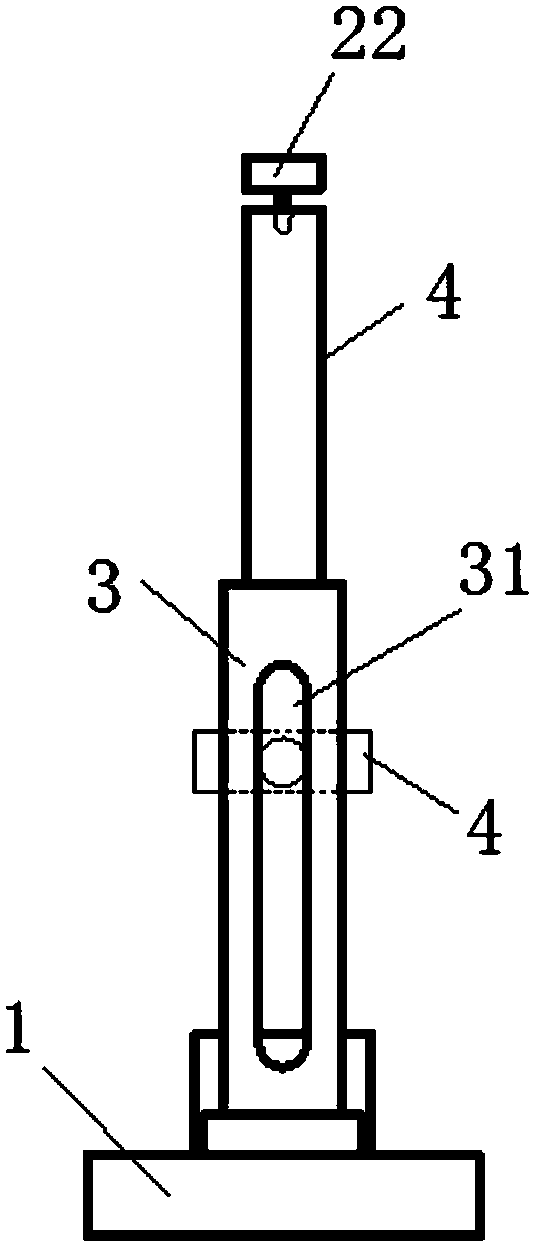

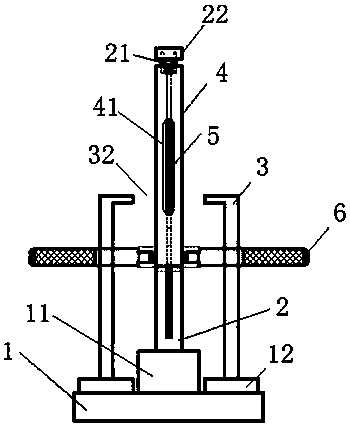

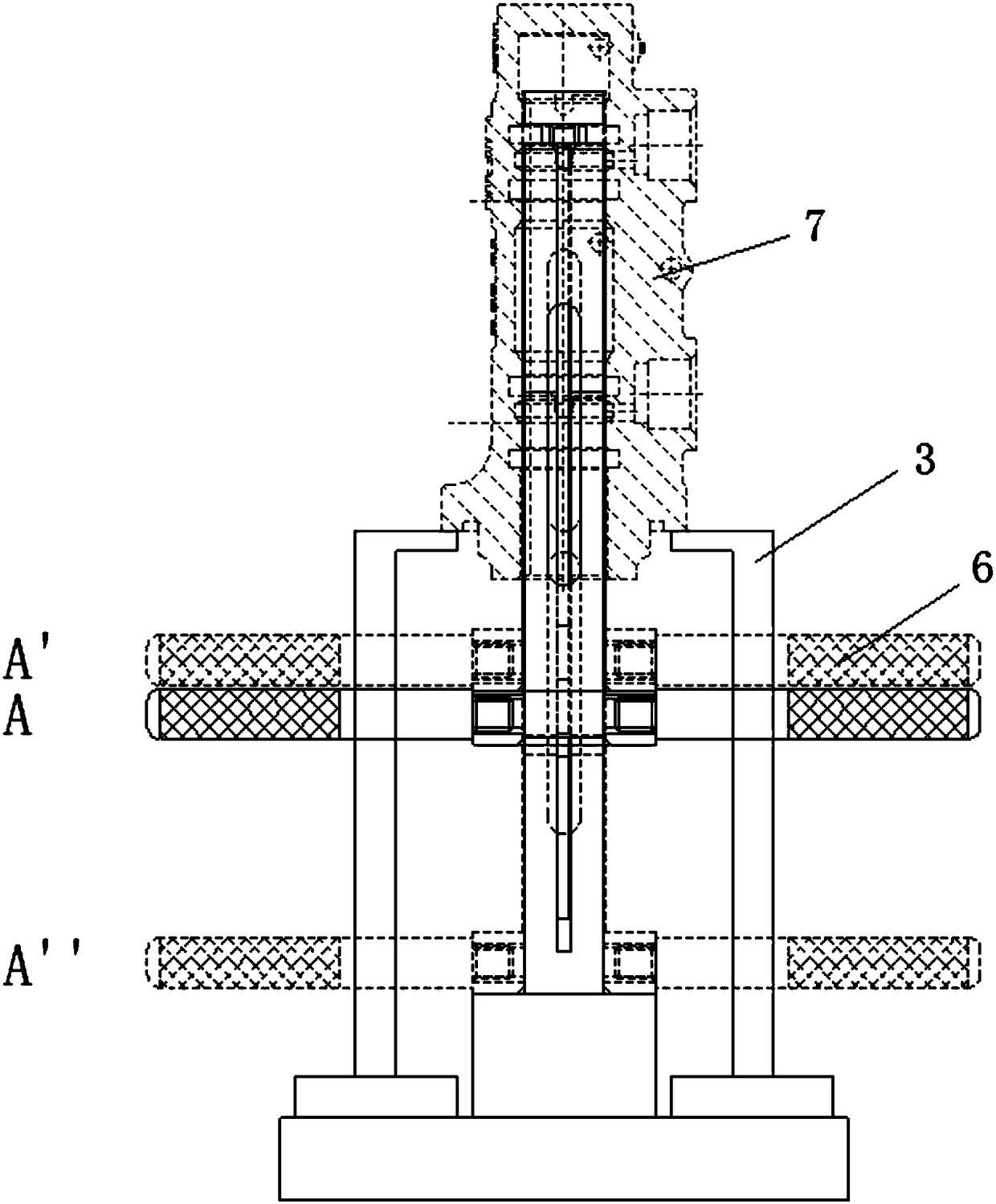

[0026] like figure 1 and figure 2 As shown, the piston pump cylinder body cup assembly device includes a fixed base plate 1, an installation mandrel 2 vertically installed on the fixed base plate 1, and a limit bracket 3 that is sheathed at the bottom of the installation mandrel. Wherein, the fixed base plate 1 is provided with a limit bracket block 11 to support the limit bracket 3, and also has an installation mandrel support block 12 supported on the bottom of the support and installation mandrel. The top of the installation mandrel 2 is provided with a cup installation groove for folding the cup into a U shape, and a protective sleeve 4 that can move up and down is nested on the radial outer side of the installation mandrel. At this time, the protection sleeve 4 is moved up and penetrated into the inner hole of the plunger pump cylinder. At this time, the protection sleeve 4 completely wraps the leather cup in the leather cup installation groove, so as to avoid the leath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com