Airbag drum machine

A technology of reeling machine and airbag, applied in the field of reeling machine of high-strength airbag, can solve the problems of manual labor that cannot be completed or is difficult to complete, and achieves the effects of being beneficial to health, improving productivity and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

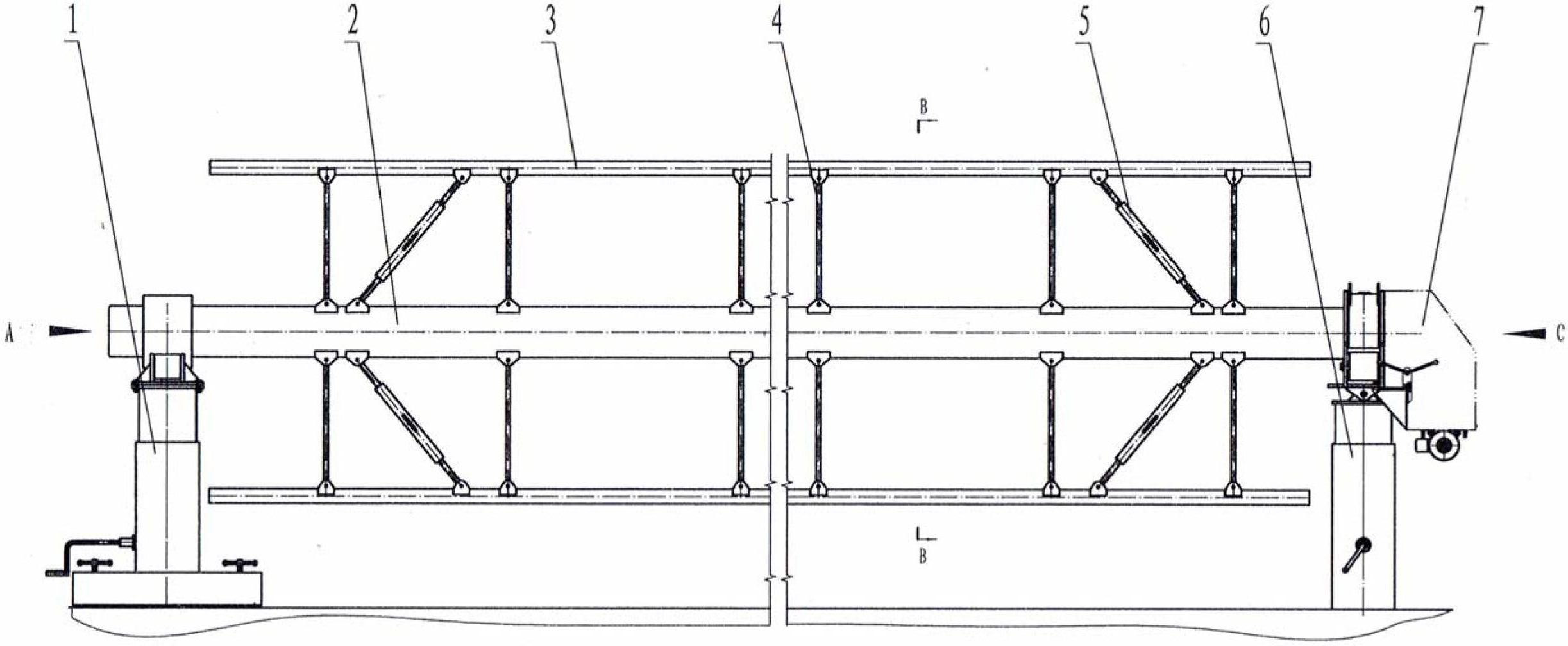

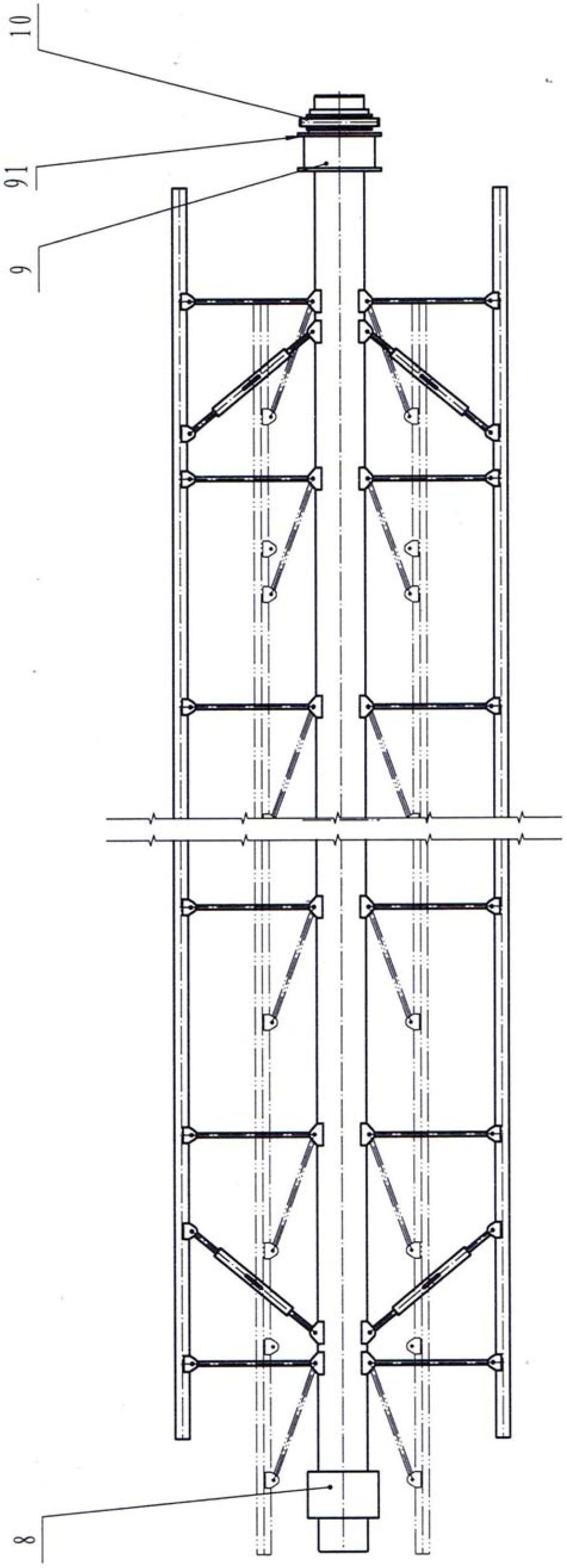

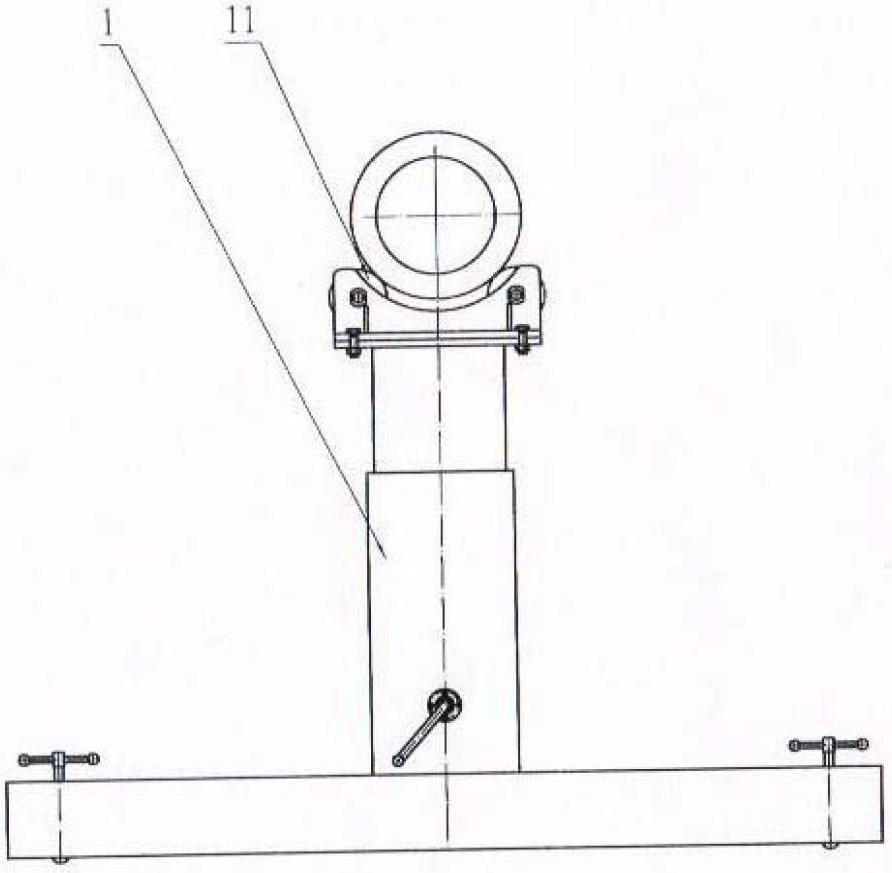

[0037] Such as figure 1 As shown, an airbag reel machine includes a main shaft 2, a power system 7 for driving the main shaft to rotate, and a secondary shaft 3 arranged parallel to the main shaft 2 on the outside of the main shaft. The secondary shaft 3 is fixedly connected to the main shaft 2 and connected to the main shaft 2 Synchronous rotation, used to carry winding accessories.

[0038] The number of auxiliary shafts 3 can be one, and in order to make the main shaft 2 receive even force when it is running, two or more auxiliary shafts 3 are arranged symmetrically on the outside of the main shaft 2 . Preferably, the number of auxiliary shafts 3 is an even number, symmetrically arranged with the main shaft 2, generally two, so that the wound airbag body is flat and symmetrical, which is convenient for stacking. When the diameter of the wrapped airbag body is too large, use four auxiliary shafts instead, which can reduce the turning space of the winding mold. figure 1 Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com