Forced centrifugal fine filter and engine of forced centrifugal fine filter

A fine filter and centrifugal technology, which is applied in the installation/connection of lubricant purification devices, lubricated parts, pressure lubricants, etc., can solve problems that affect the service life of components, have no purification effect, affect the crankshaft, etc., and achieve good centrifugal Filtration ability, easy to clean, easy to disassemble and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

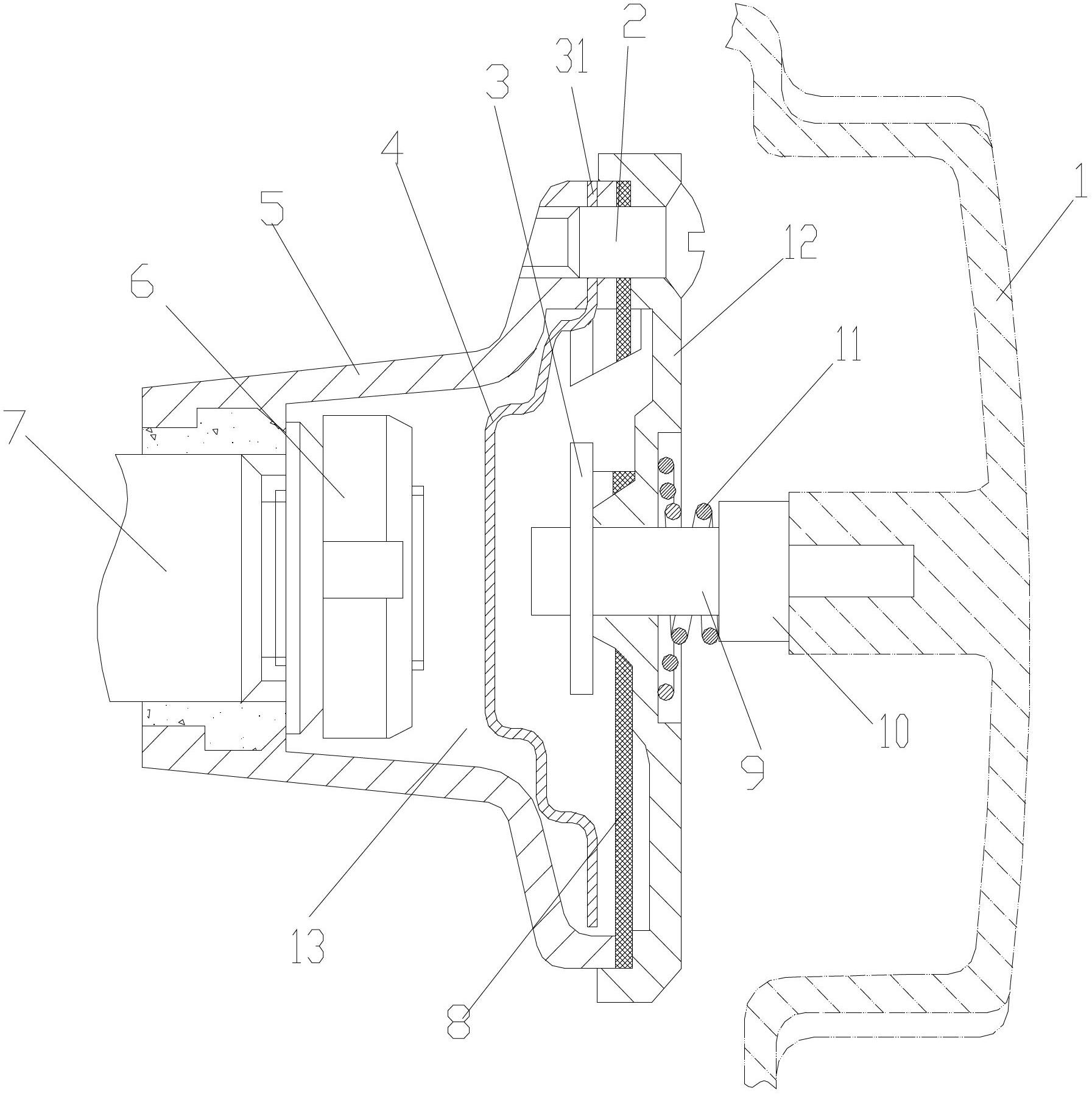

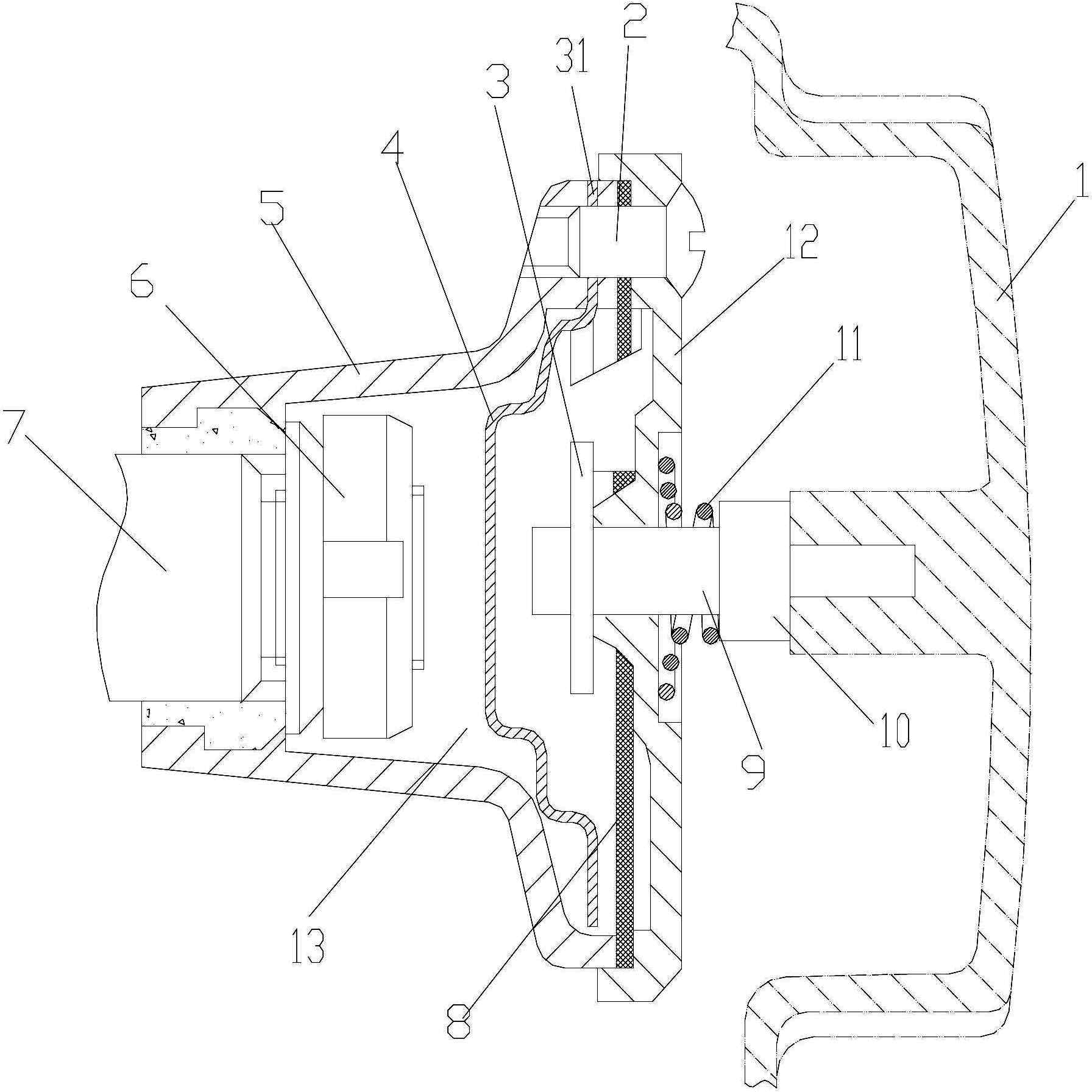

[0019] figure 1 It is a schematic diagram of the cross-sectional structure of the present invention, as shown in the figure: the forced centrifugal fine filter of the present embodiment includes a fine filter mounting seat 5 for being installed on the end of the crankshaft and fixedly matched with the fine filter in the circumferential direction and for connecting with the fine filter. The mounting base 5 together forms the sealing cover 12 of the fine filter cavity 13. As shown in the figure, the sealing cover 12 is fastened and installed on the fine filter mounting base 5 through screws 2, and a sealing gasket 8 is provided on the bonding surface to achieve a better sealing effect. Be located in fine filter cavity 13 and be fixedly connected with fine filter mounting seat 5 in circumferential direction and be provided with centrifugal separation plate 4, as shown in the figure, the rotational axis of centrifugal separation plate 4 coincides with the rotational axis of fine fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com