Oil centrifugal anti-leakage fine filter and its engine

A fine filter and centrifugal technology, applied in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc., can solve problems such as high precision of end surface processing, leakage of lubricating oil, accidents, etc., to achieve Avoid the problem of lubricating oil leakage, reduce the axial size, and improve the effect of centrifugal filtration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

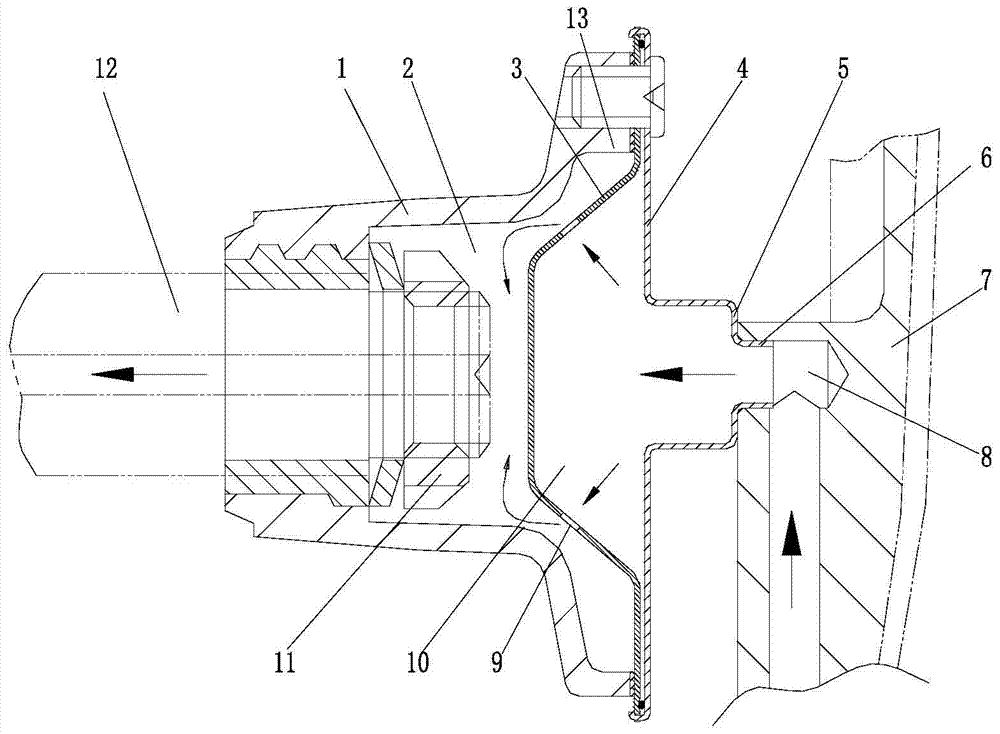

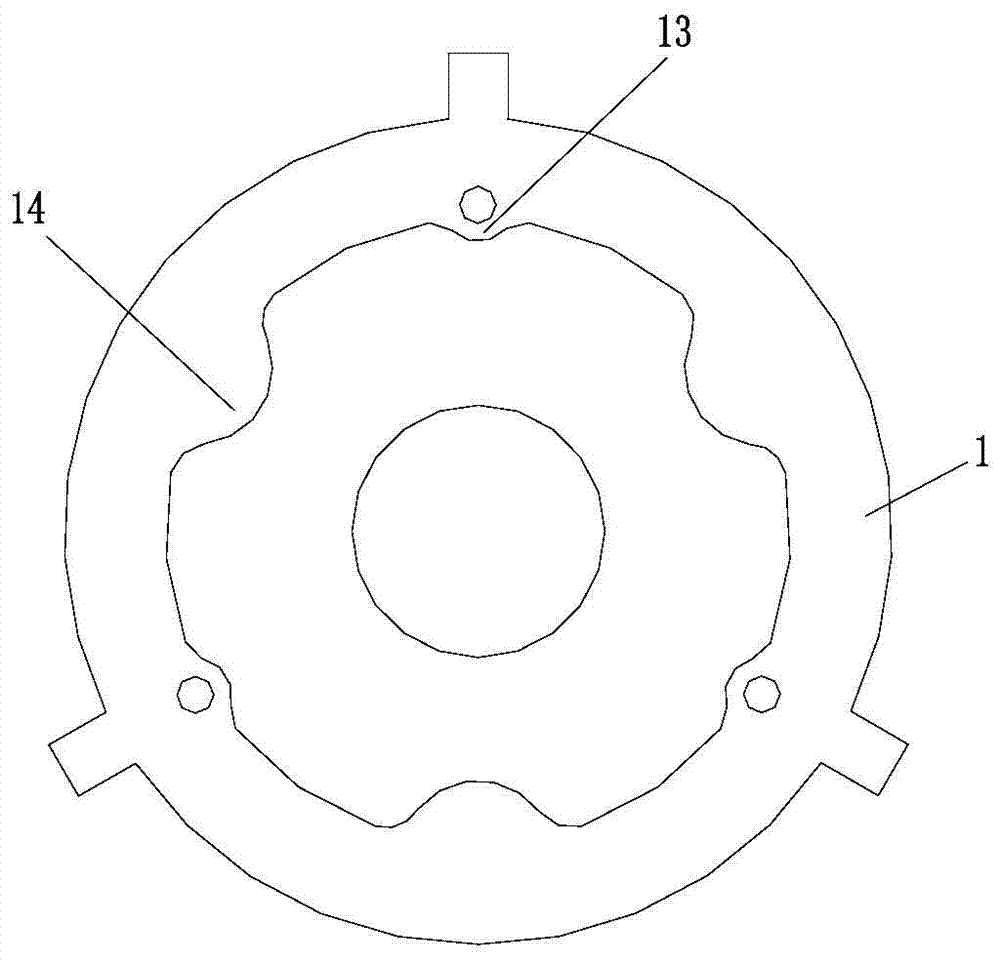

[0023] figure 1 It is a sectional view of the present invention, figure 2 It is an end view of the fine filter mounting seat, as shown in the figure: the oil centrifugal anti-leakage fine filter of this embodiment includes a fine filter mounting seat 1 for being installed on the end of the crankshaft and fixedly matched with the fine filter in the circumferential direction and for connecting with the fine filter. The filter mounting base 1 together forms the sealing cover 4 of the fine filter cavity, which is located in the fine filter cavity and is sealed and connected with the fine filter mounting base 1 in the circumferential direction. A centrifugal separation plate 3 is provided. The sealing cover 4 is formed by stamping, and the sealing cover 4 is integrally formed with a belt There is an oil inlet pipe joint 6, and the oil inlet pipe joint 6 penetrates into the oil outlet passage 8 of the crankcase cover 7 in a rotationally fitted and sealed communication manner, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com