Centrifugal fine filter and its engine

A fine filter, centrifugal technology, applied in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc., can solve the problems of affecting the circulation of lubricating oil, affecting the use of running parts, and insufficient active driving effect, etc. Achieve the effect of ensuring sufficient supply, increasing flow area, and increasing centrifugal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

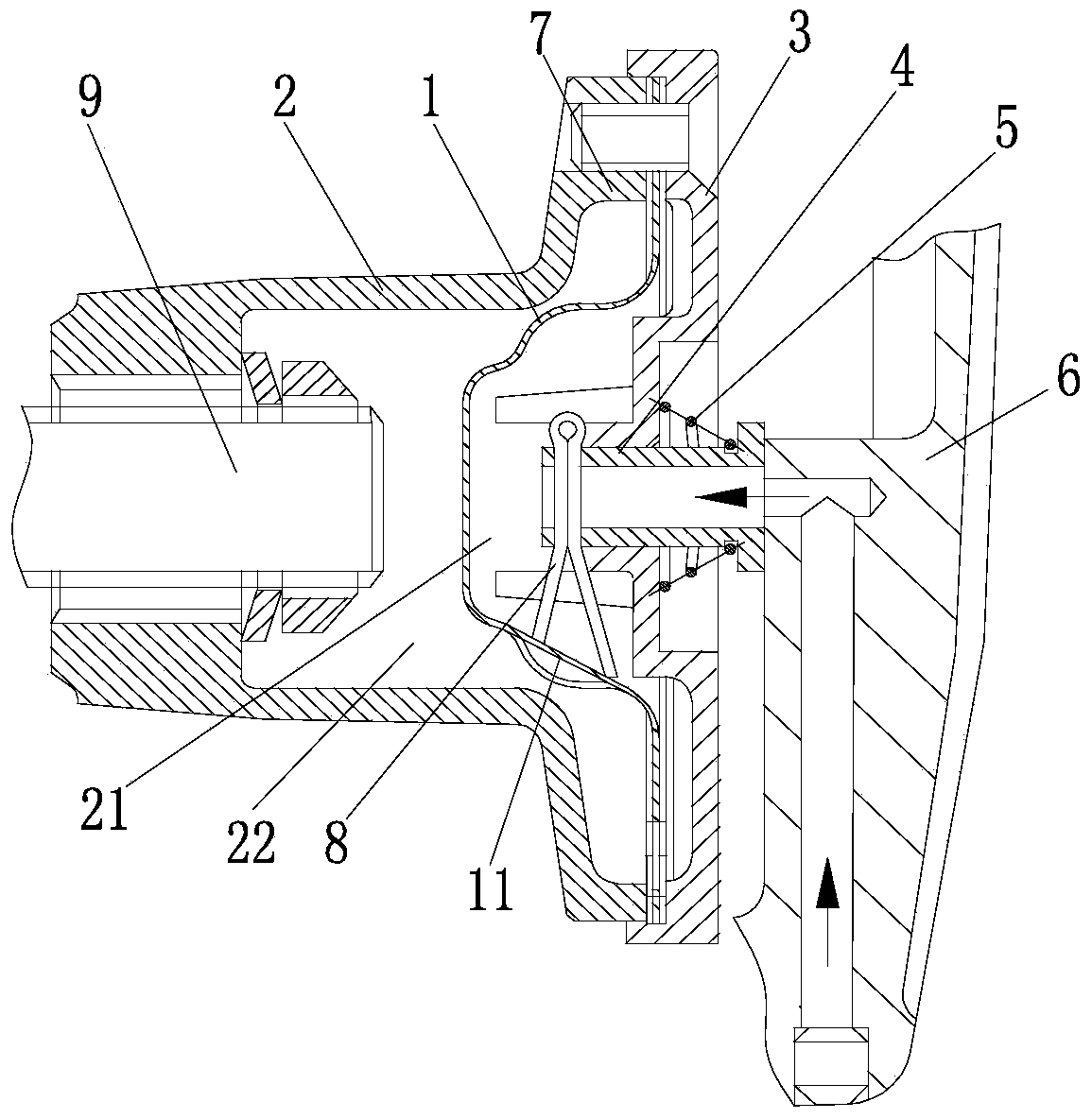

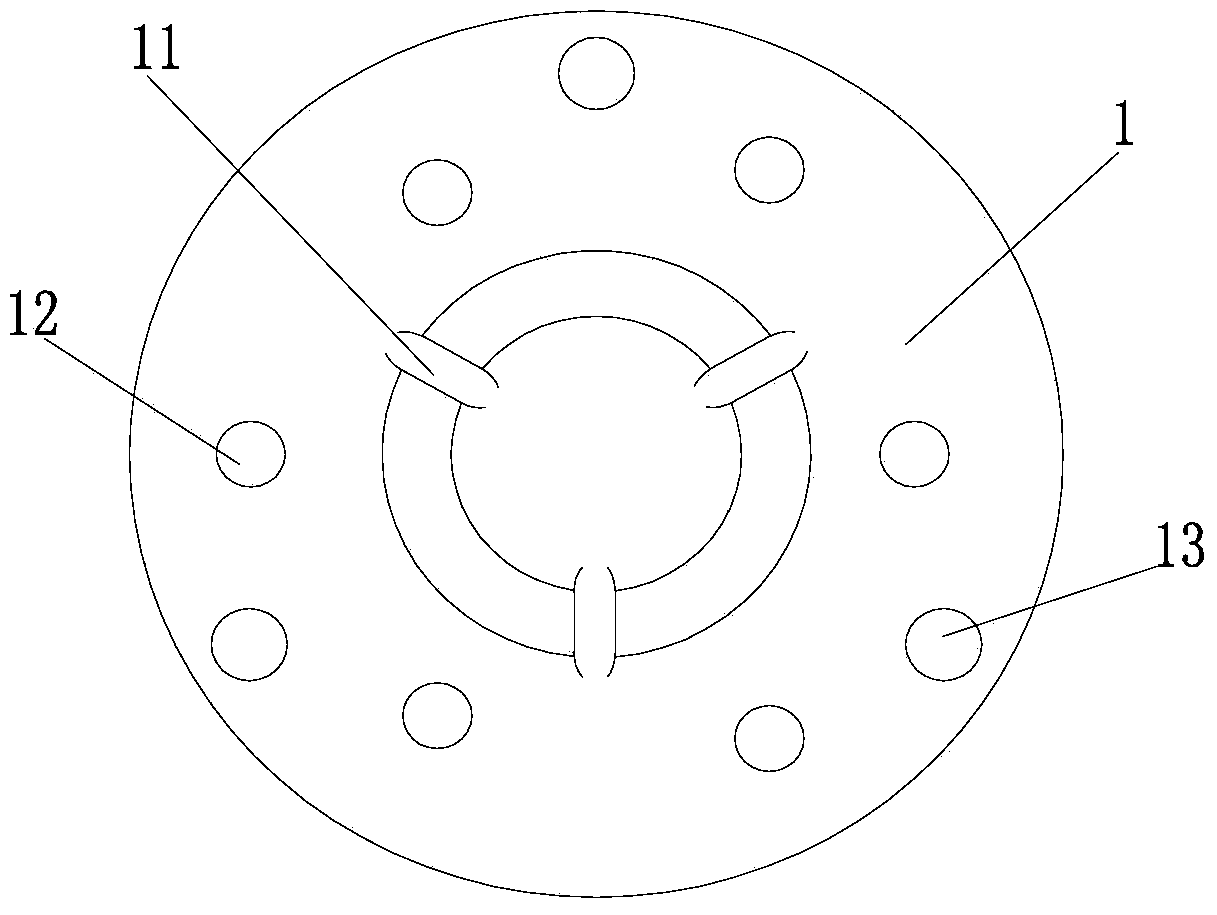

[0020] figure 1 It is a sectional view of the present invention, figure 2 It is an axial view of the centrifugal separation plate, as shown in the figure: the centrifugal fine filter of this embodiment includes a fine filter mounting seat 2 and a centrifugal separation plate 1 installed on the fine filter mounting seat 2, the centrifugal separation plate 1 front The surface or / and the rear surface are provided with grooves 11 or / and protrusions for changing the oil flow channel and increasing the centrifugal force; the fine filter generally also includes a sealing cover 3 for forming a fine filter chamber together with the fine filter mounting seat 2, The centrifugal separation plate 1 divides the fine filter chamber into a front fine filter chamber 21 and a rear fine filter chamber 22, and the centrifugal separation plate 1 should have an oil hole 12 (or channel) communicating with the front fine filter chamber 21 and the rear fine filter chamber 22 , the front fine filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com