Method for determining actual heat consumption of steam extraction heat supply machine

A steam extraction heat supply unit, heat consumption technology, applied to calorimeters, heat measurement, instruments, etc., can solve the problems of low heat consumption accuracy and increased workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

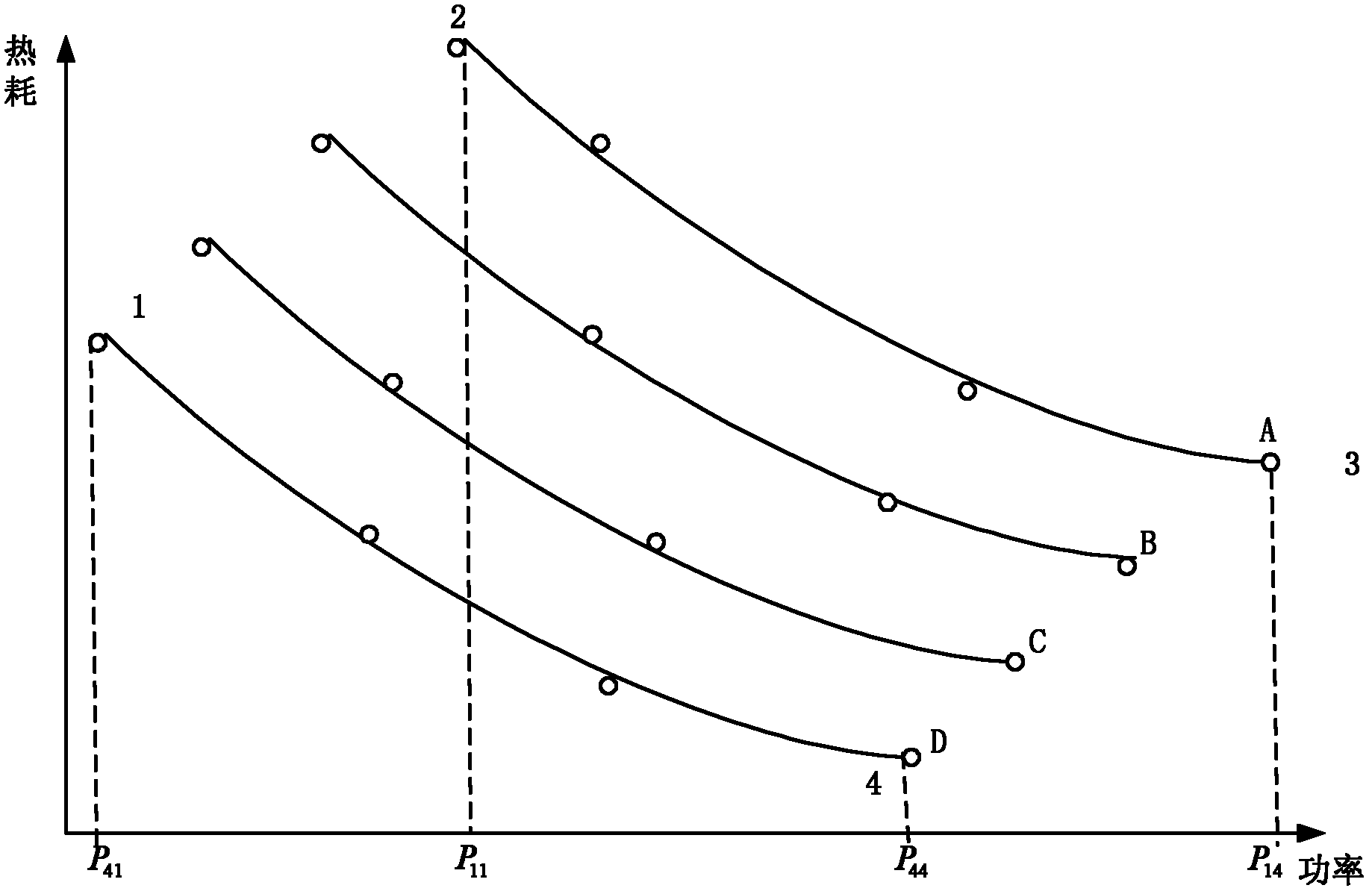

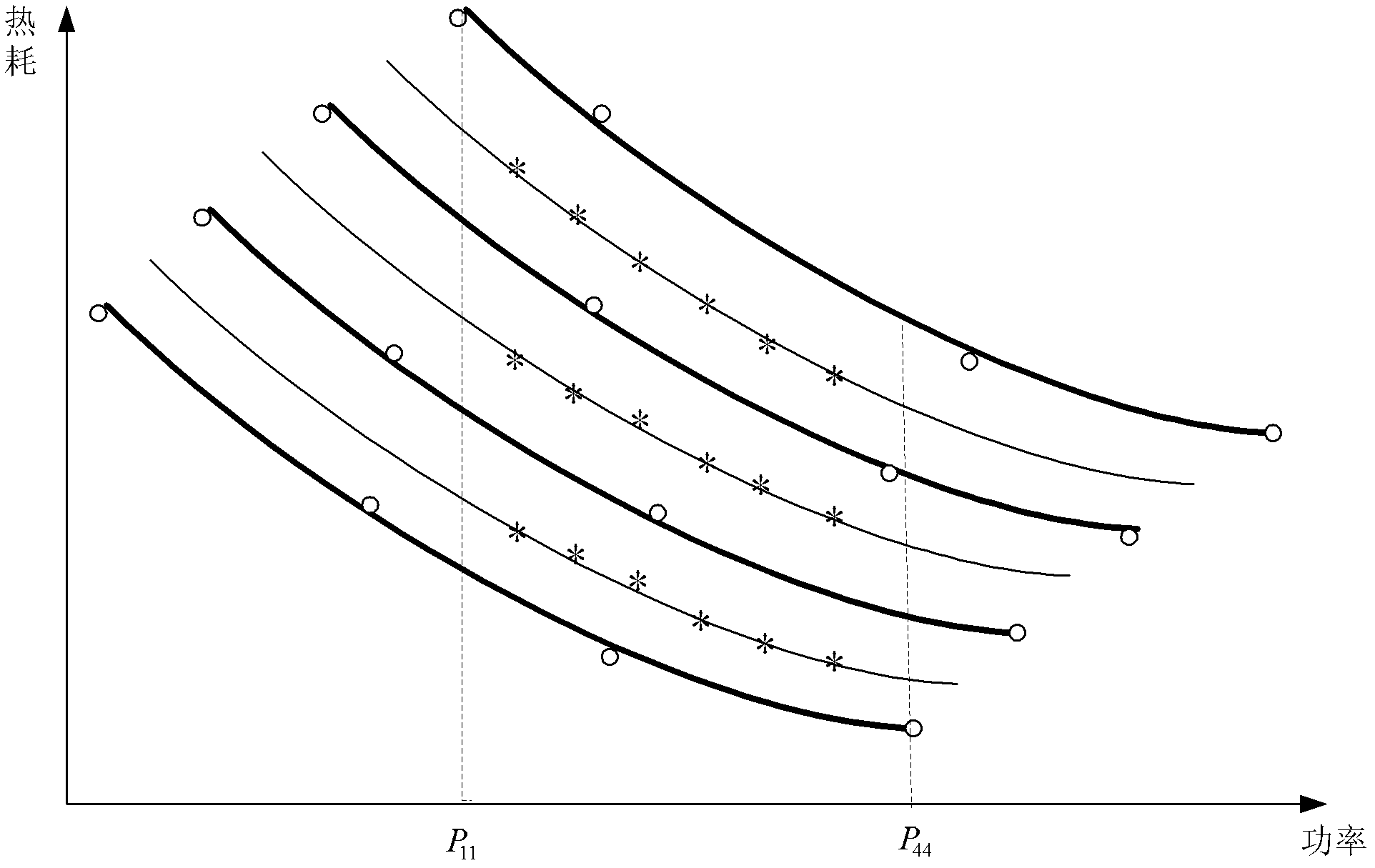

[0022] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a method for determining the actual heat consumption of the extraction steam heating unit described in this embodiment, the parameters of the extraction steam heating unit are:

[0023] According to the steam turbine thermal performance assessment test regulations, the formula for calculating the heat consumption rate of the unit is:

[0024] H rt = F ms × H ms - F fw × H fw - F shsp × H shsp + F c...

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the specific process of the joint method of maximum likelihood estimation method and AIC criterion described in step 1 is:

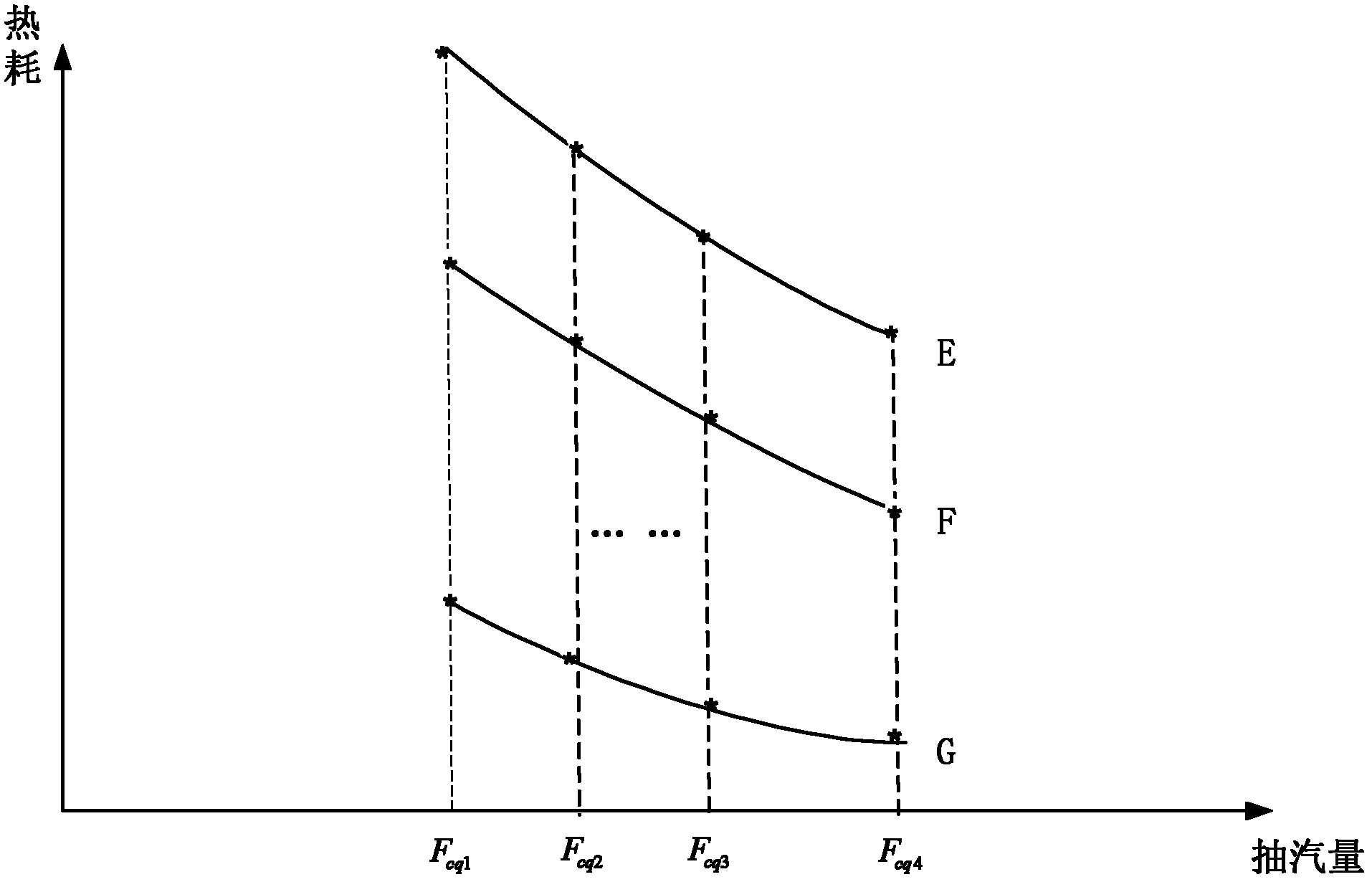

[0040] Extraction steam for heating F cq Certain, independent variables are steam turbine power P, heat consumption H rt The relationship between the dependent variables is fitted; the independent variables are steam turbine power P, heat consumption H rt The relationship between the dependent variable is a polynomial model and the model error satisfies a normal distribution;

[0041] Dependent variable heat consumption H rti The relationship with the independent variable steam turbine power P is expressed by formula 3:

[0042] h rti =a 0 +a 1 P+a 2 P 2 +…+a n P n +ε i Formula 3

[0043] The parameter ε in Equation 3 i Indicates that the mean is zero and the variance is δ 2 A random variable with a normal distribution, denoted by ε i ~N(0,δ 2 ), para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com