Clutch and separation device for running-in rack of engine

A separation device and engine technology, applied in the direction of engine testing, measuring devices, machine/structural component testing, etc., can solve misjudgment (shifting card, unable to shift, affecting transmission shifting performance, shortening the use of transmissions) Life and other issues, to achieve the effect of saving fault detection time, easy and labor-saving shift operation, ensuring performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

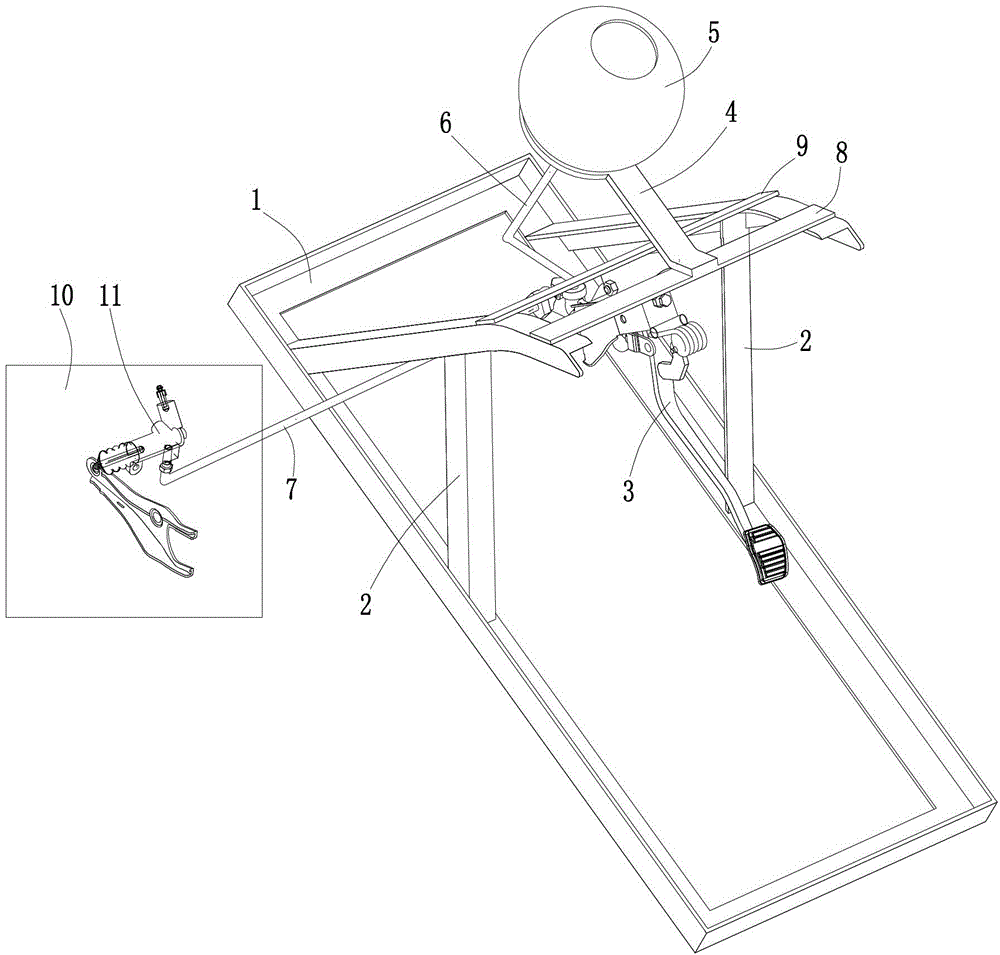

[0015] Such as figure 1 Shown, the present invention is made of components such as underframe 1, side support 2, clutch pedal assembly 3, upper support 4, oil storage tank 5, first oil pipe 6, second oil pipe 7, upper beam 8 and lower beam 9. Wherein, the bottom frame 1 is preferably a rectangular frame structure, and side brackets 2 are arranged on the front of the two long sides of the bottom frame 1, and the side brackets 2 on the left and right sides are symmetrically distributed. The side support 2 is preferably in the shape of a "person", the left side support 2 is on the same vertical plane as the long side on the left side of the underframe 1, and the right side support 2 is on the same vertical plane as the long side on the right side of the underframe 1. , and the front and rear ends of the bottom of the side support 2 are welded to the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com