Self-detection method for rotating mechanism control system in airborne photoelectric detection device

A rotating mechanism and control system technology, applied in the field of photoelectric detection, can solve the problems of time-consuming, labor-intensive, labor-intensive and time-consuming, and achieve the effect of reducing fault detection time and improving fault detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

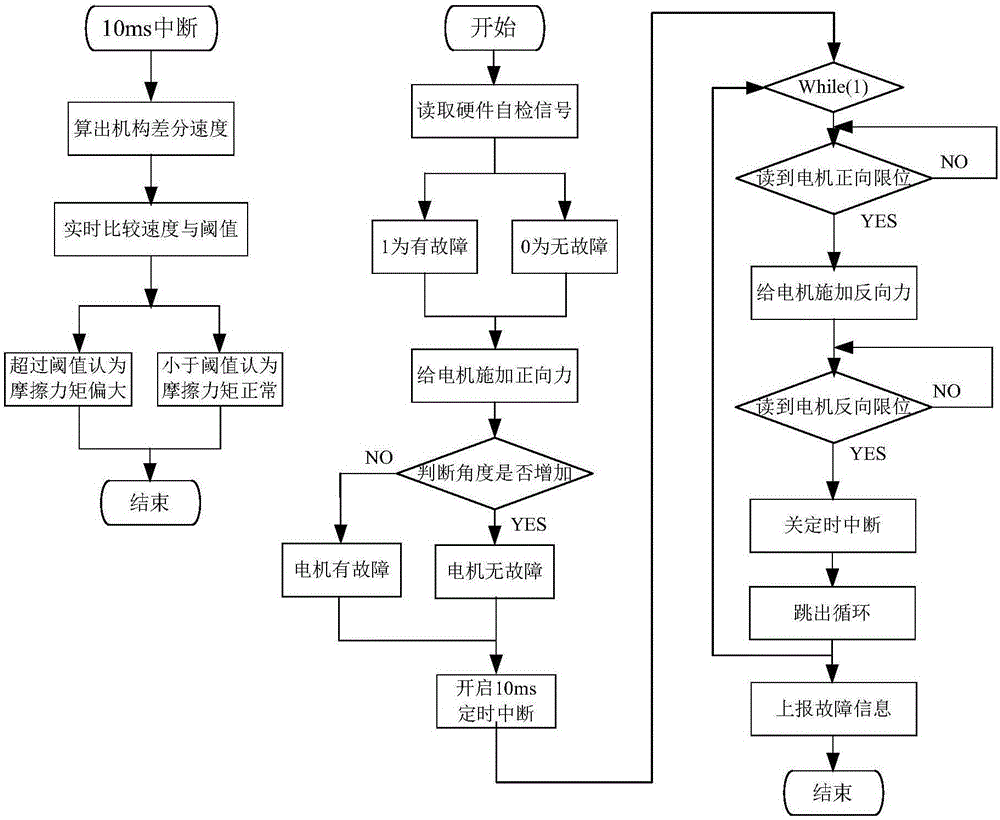

[0018] The invention proposes a self-inspection method for the control system of the rotating mechanism in the airborne photoelectric detection equipment, which is directly embedded in the follow-up control program of the rotating mechanism of the airborne photoelectric detection equipment. The results are reported to the task machine. Among them, the angle-measuring code disc, speed-measuring gyroscope, power supply board, and power amplifier board all have hardware self-inspection signals. By reading the hardware self-inspection signal, it is judged whether it is working normally; the motor has no self-inspection signal. On the basis of the normal operation of the board, apply a positive force to the motor. If it is detected that the angle of the code disc i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com