A device and method for real-time detection of fan blade downconductor breakage

A real-time detection and down-conductor technology, applied in the direction of measuring devices, wind power generation, continuity testing, etc., can solve the problems of property loss, reducing the utilization rate of wind turbines, low efficiency and subjectivity, etc., to achieve accurate measurement data and ensure safety and stability running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

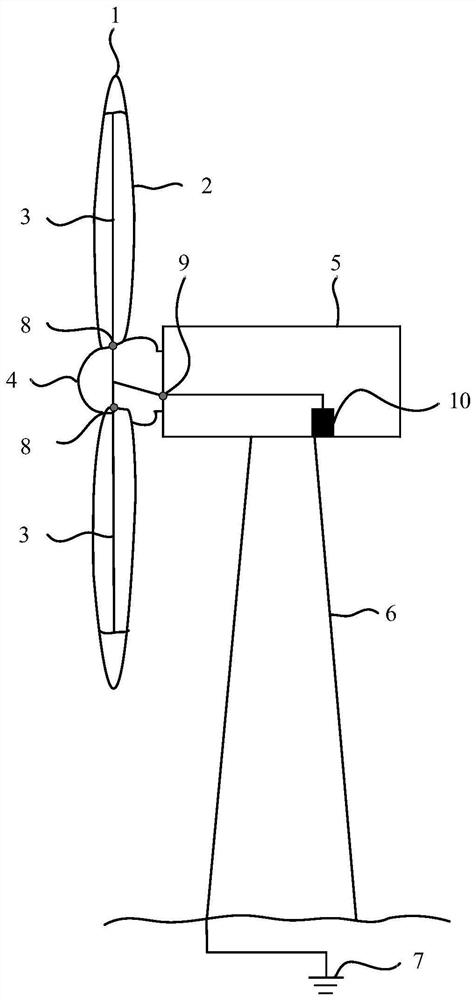

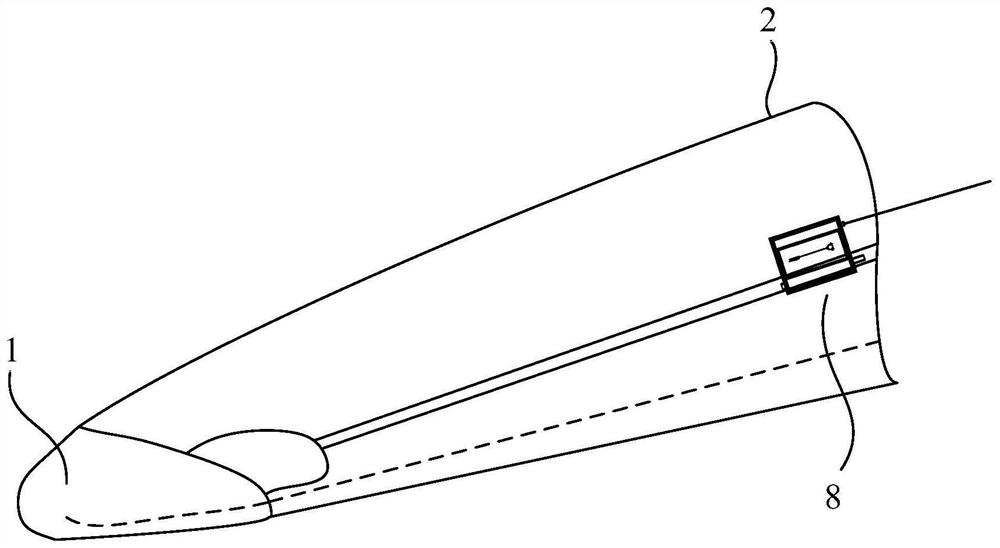

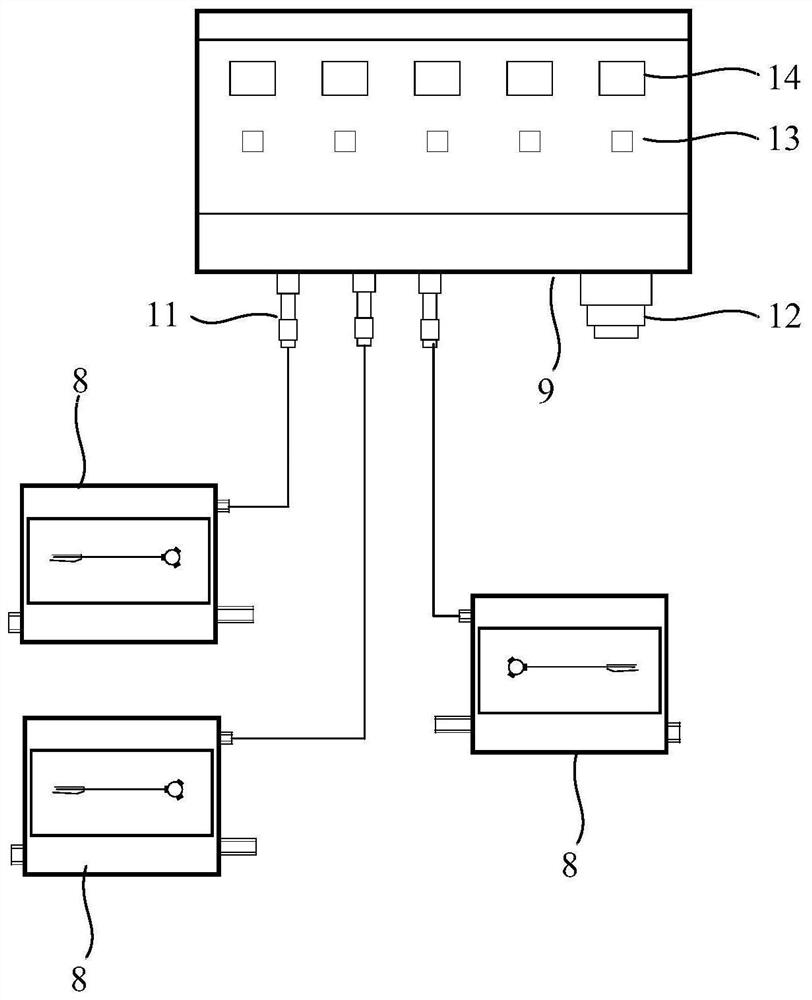

[0038] In the present invention, the fan blade down conductor detection system is composed of three sensors and a signal analysis and logic unit. The three sensors are respectively installed in series on the down conductors of each blade of the fan. The unit is connected, the signal analysis and logic unit is powered by 220V AC cable, and can also be connected to 24V DC power supply through the Alarm signal cable connector. The signal transmission between the local LAN and the main control room, the installation diagram of the sensor, signal analysis and logic unit in the fan is shown in figure 1 shown. The paddle flange is the flange used to connect the paddle to the fan nacelle 5 .

[0039] A novel detection device for the running state of the fan blade down-conductor is characterized in that it includes a sensor, a signal analysis and logic unit,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com