Method for on-line automatic information tracking of steel tubes

A steel pipe, automatic technology, applied in the field of automatic information tracking, can solve the problems of information loss, large manpower organization, loss of identification, etc., and achieve the effect of simple coding method, simple coding system and high recognition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

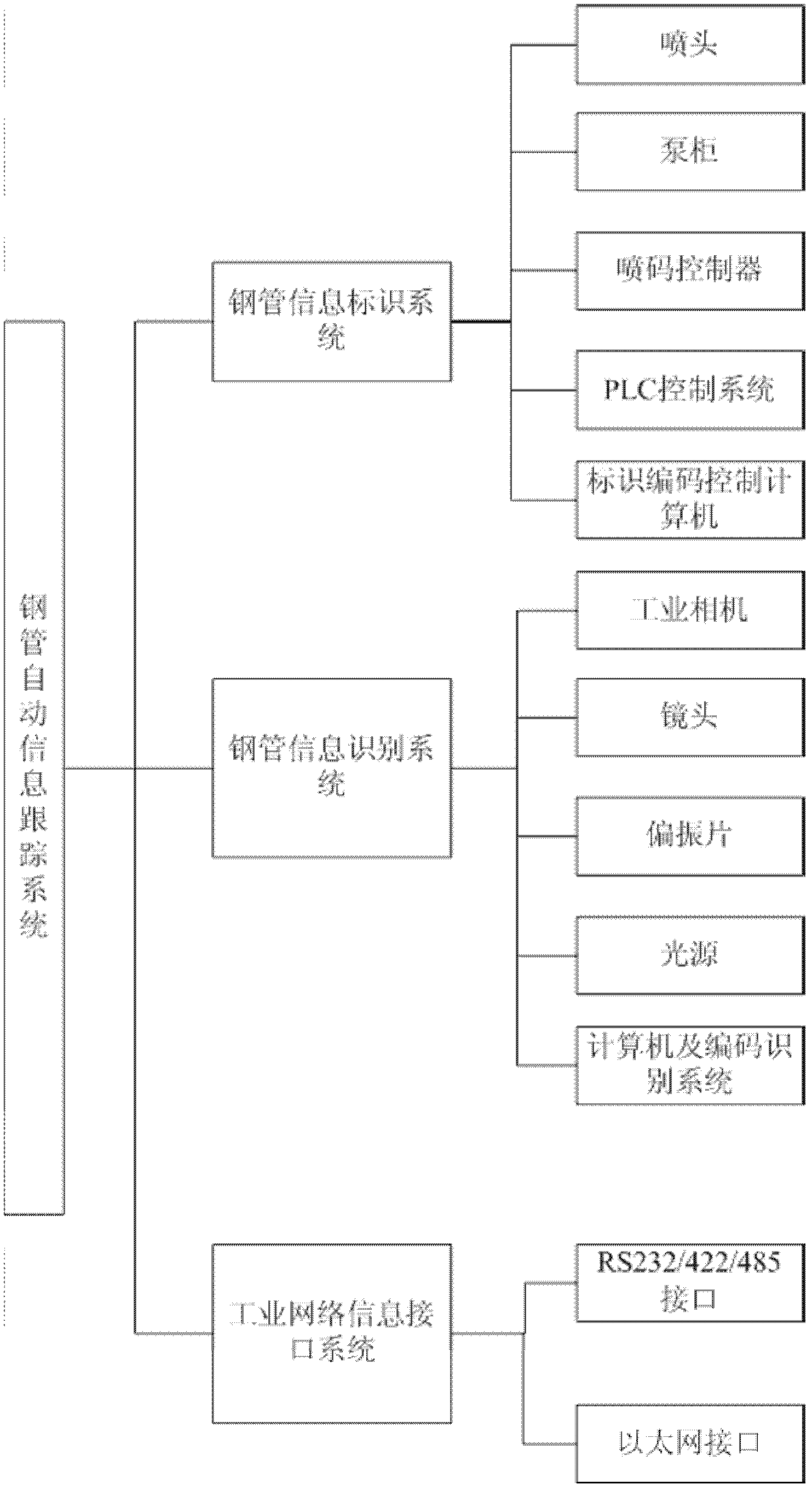

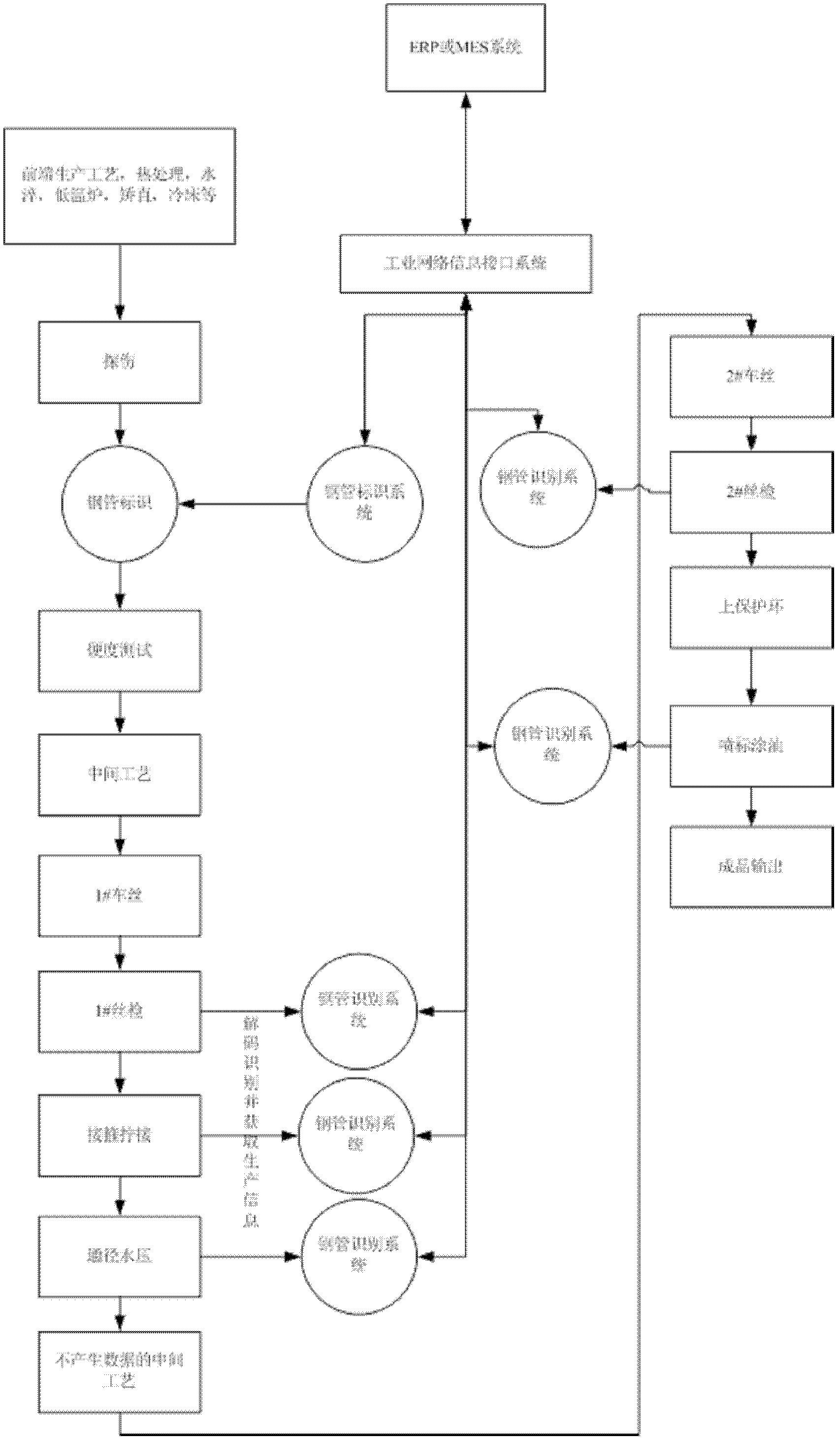

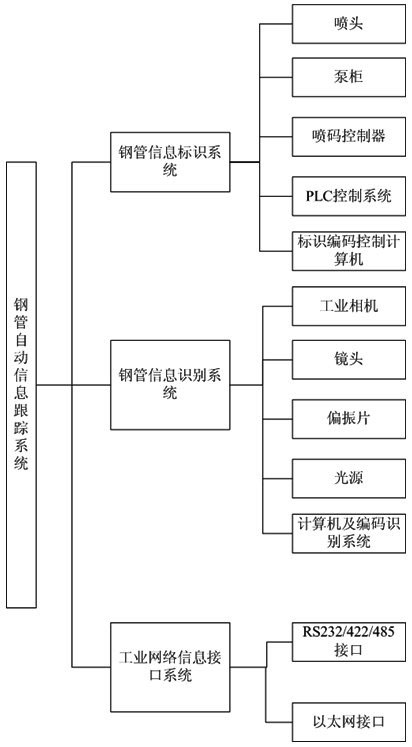

[0019] Such as figure 1 As shown, the present invention includes three parts: a steel pipe information identification system, a steel pipe information identification system, and an industrial network information interface system; wherein the original information of the steel pipe is transmitted to the steel pipe information identification system by the MES or ERP network through the industrial network information interface system, and the steel pipe information The identification system converts the original information of digital steel pipes into barcode + digital information to mark on the surface of steel pipes, and the steel pipe information identification system collects images of steel pipe surfaces in each station of the production line, and converts the images into recordable original digital quantities Information, through the industrial networ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com