Manufacture information multi-dimension classification coding method for aerospace product structural element

A technology of product structure and coding method, applied in the field of classification and coding, can solve the problems of complex classification of aerospace product structural parts manufacturing information, many coding systems, difficult conversion, etc., to achieve the effects of easy dynamic management, high processing efficiency, and concise coding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

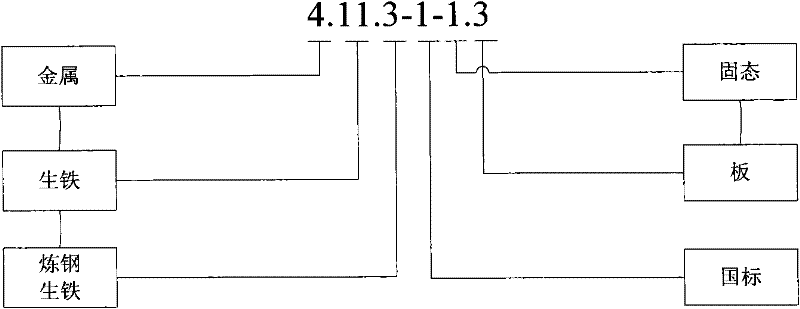

[0031] The present invention will be further described below in conjunction with the specific embodiments of the accompanying drawings and the material classification coding of aerospace product structural parts:

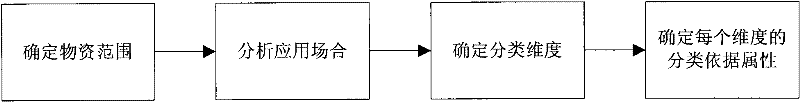

[0032] Such as figure 1 The shown multi-dimensional classification setting process is divided into four steps: determining the scope, analyzing the application occasion, determining the classification dimension, and determining the classification basis attribute of each dimension.

[0033] (1) Determine the scope

[0034] In this example, materials such as raw materials, auxiliary materials, and standard parts of structural parts of aerospace products are used as the range of classification codes.

[0035] (2) Analyzing application occasions

[0036] The types of work related to this classification code include product design, process design and management, model project management, financial management, quality management, procurement management, warehouse manage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com