Dangerous goods monitoring method based on radio frequency identification

A radio frequency identification and dangerous goods technology, applied in the field of RFID technology, can solve the problems of large material resources, labor-intensive, complicated operation, etc., and achieve the effect of highlighting precise management, improving work efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

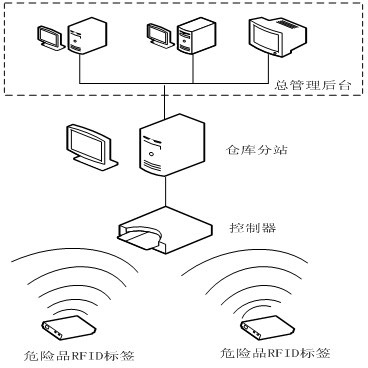

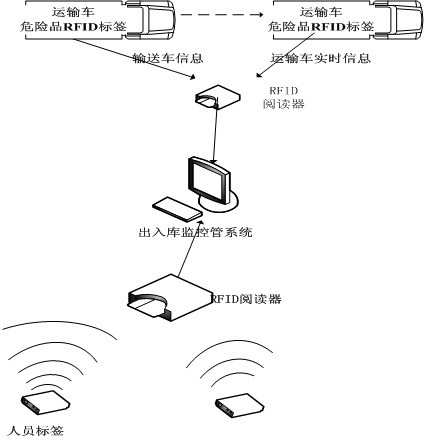

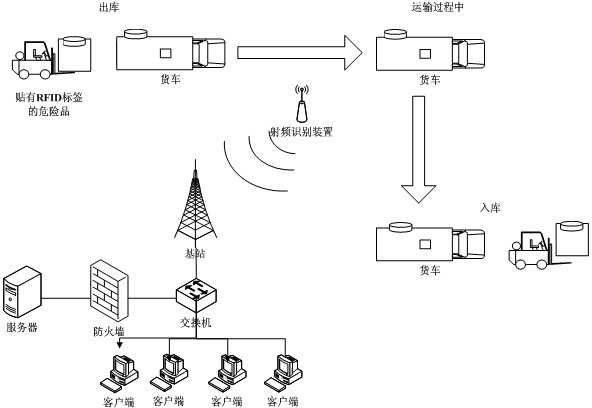

[0018] In order to solve these problems, the advanced radio frequency identification (RFID) technology is introduced into the existing dangerous goods management, and the dangerous goods monitoring method based on RFID is designed. It automatically collects the data of the dangerous goods warehouse arrival inspection, warehousing, outbound, warehouse shifting, dangerous goods inventory, transportation, etc., to ensure the speed and accuracy of data input in each link of dangerous goods warehouse management To ensure that enterprises can grasp the real data of inventory in a timely and accurate manner. After adopting RFID technology, it will bring huge benefits to the enterprise: (1) save the cost of manual data collection; (2) automate dangerous goods warehouse management operations, improve work efficiency; (3) reduce management costs and human errors; (4) ) more accurate inventory of dangerous goods; (5) increase the safety of managers; (6) modernize and automate the managem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com