Automatic control system for ozone generation and water treatment

An automatic control system and ozone generation technology, which are used in oxidized water/sewage treatment, ozone preparation, etc., can solve the problems of unguaranteed water quality, inability to track and adjust operating parameters in time, energy waste, etc., to extend the service life of equipment, A wide range of applications and the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

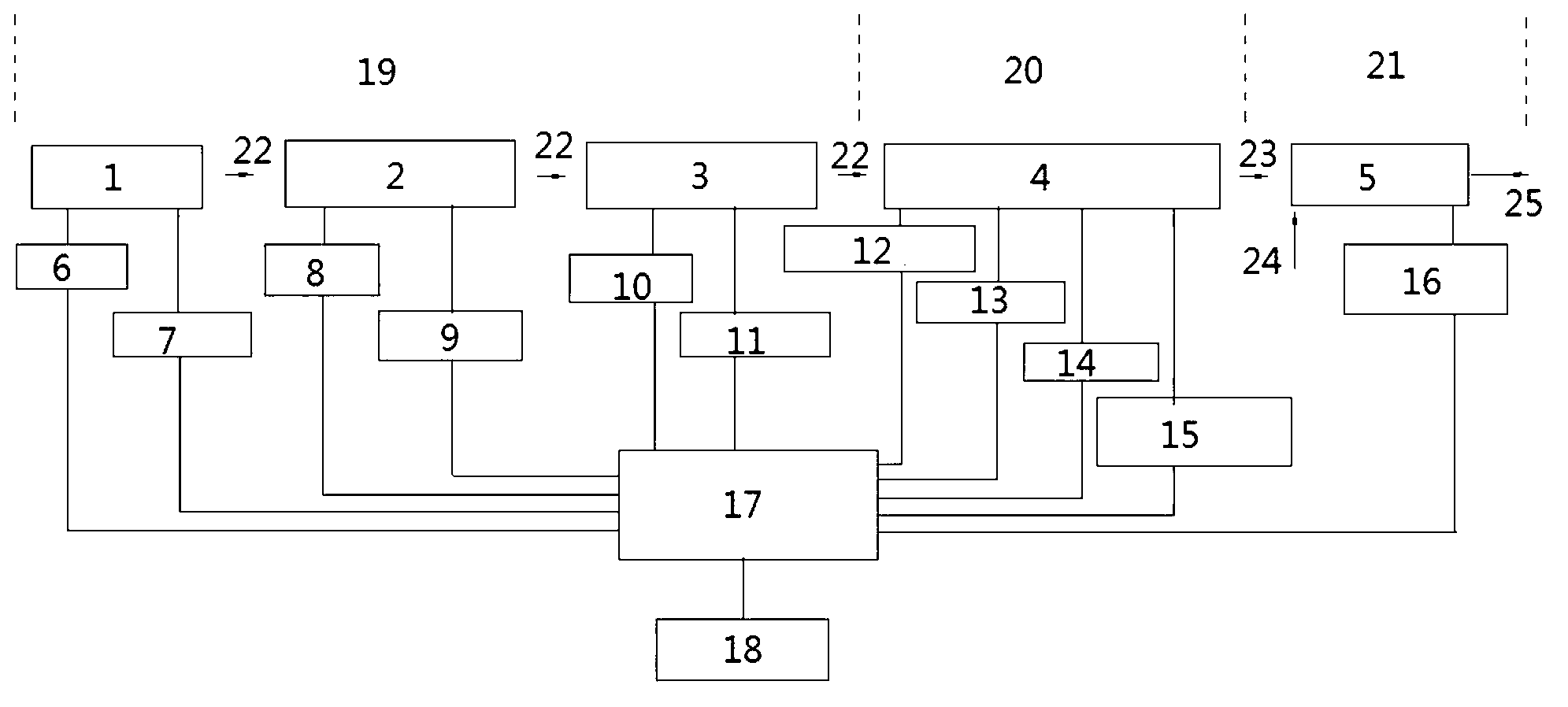

[0032] An automatic control system for ozone generation and water treatment, comprising a PLC controller 17 and a first frequency converter 6 connected to the PLC controller 17, a pressure transmitter 7, a second frequency converter 8, a temperature transmitter 9, Controller 10, dew point detector 11, frequency and voltage regulation power supply 12, vortex flowmeter 13, electric valve 14, ozone concentration on-line detector 15, oxidation treatment on-line detector 16. The air compressor 1, the cold dryer 2, and the adsorption dryer 3 form the air source treatment system 19; the ozone generator 4 forms the ozone generation system 20; the oxidation tower 5 forms the oxidation treatment system 21; the air 22 passes through the air source treatment system 19, The ozone generation system 20 generates ozone 23, and the ozone 23 then enters the oxidation tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com