Method for the removing and reducing scaling

A technology of scaling, trimethylglycine, applied in chemical instruments and methods, descaling and water softening, special treatment targets, etc., can solve problems such as high cost, reduced use time, membrane damage, etc., to improve anti-scaling ability , the effect of eliminating accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

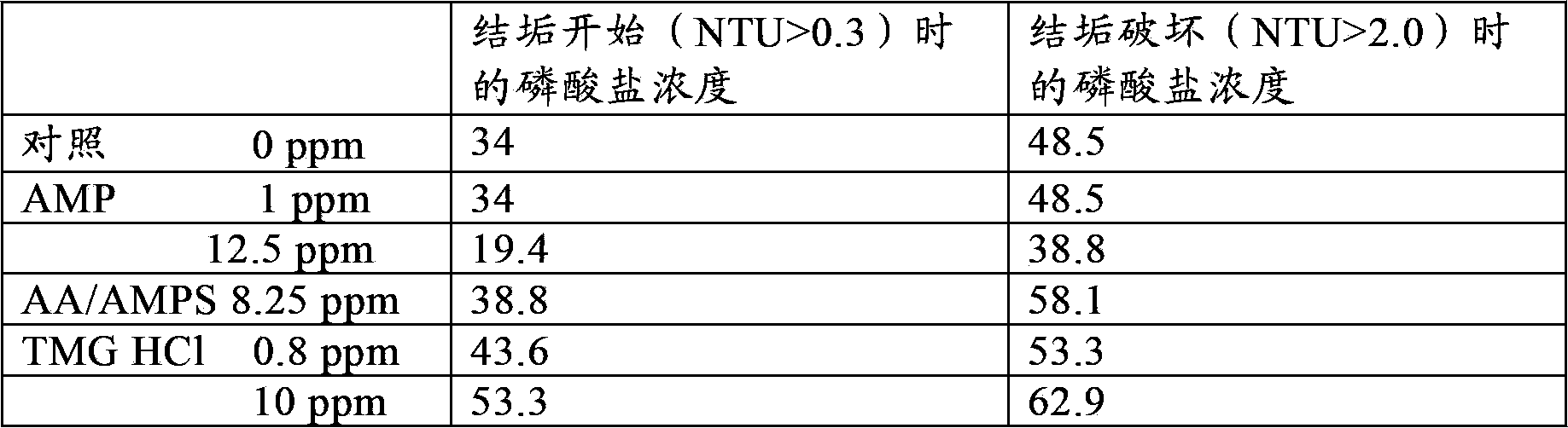

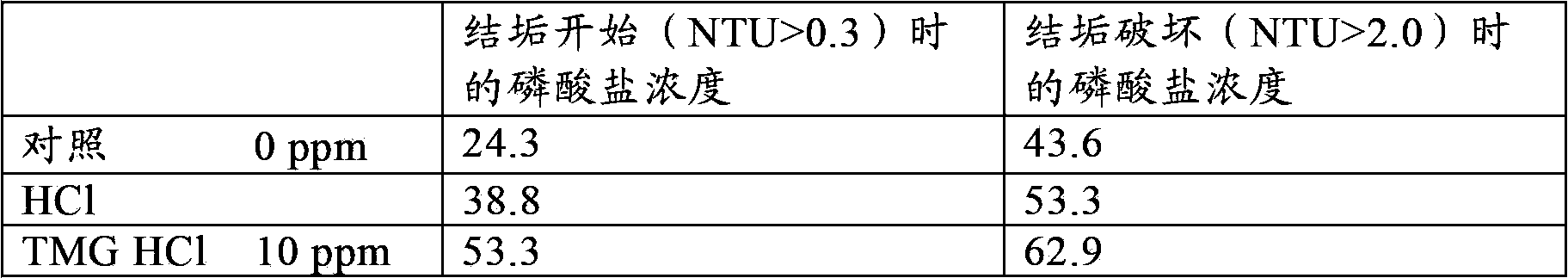

[0020] The foregoing may be better understood by reference to the following examples, the purpose of which is to illustrate the method for practicing the invention and not to limit the scope of the invention. This experiment was performed at 25 °C and an induction period of 45 min. The procedure involves using 130ml of deionized water in a Erlenmeyer flask equipped with a stir bar, adding 2 HPO 4 (0.016ml) and 0.1M CaCl 2 (40.0ml) standard solution of ions. If evaluating antiscalants, add antiscalants at this step by adding an appropriate volume of deionized water to the test to keep all total volumes the same and thus maintain the same concentration of ions. Turbidity was then measured using a hand-held turbidimeter (return the portion taken for measurement back into the mother liquor) and pH was measured using a VWRSymphony pH meter. After 45 minutes, the turbidity and pH were measured again, followed by the addition of 0.1M Na 2 HPO 4 . Finally, the above steps were ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap