Open-end spinning device

A textile machine, an open technology, applied in the direction of spinning machine, textile and paper making, open-end spinning machine, etc., can solve the problems of incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

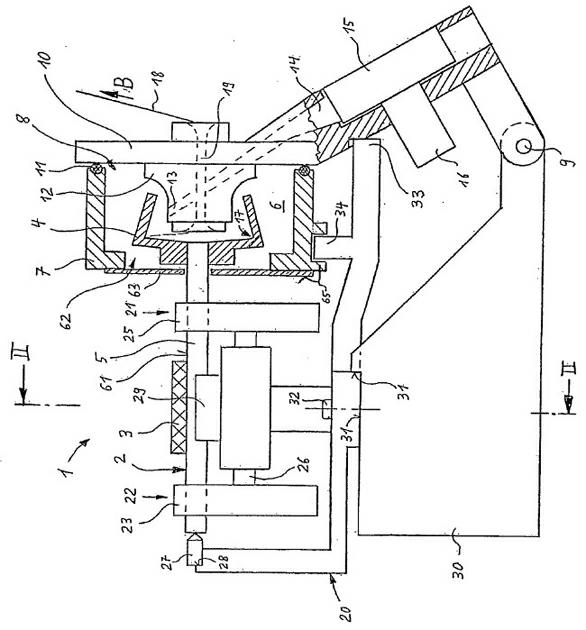

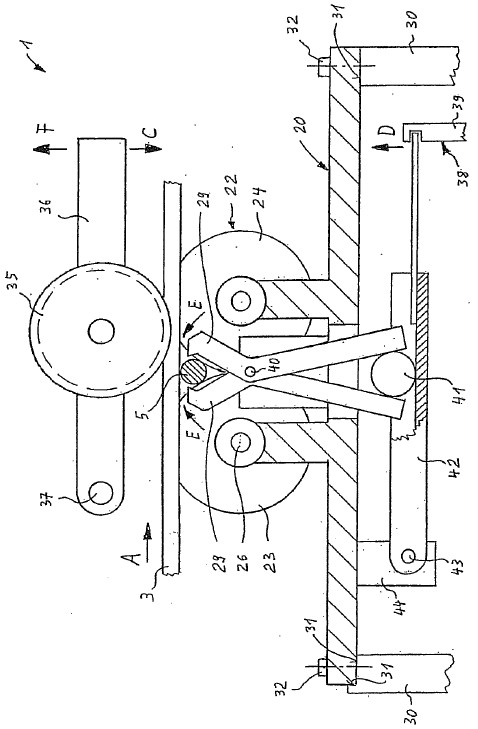

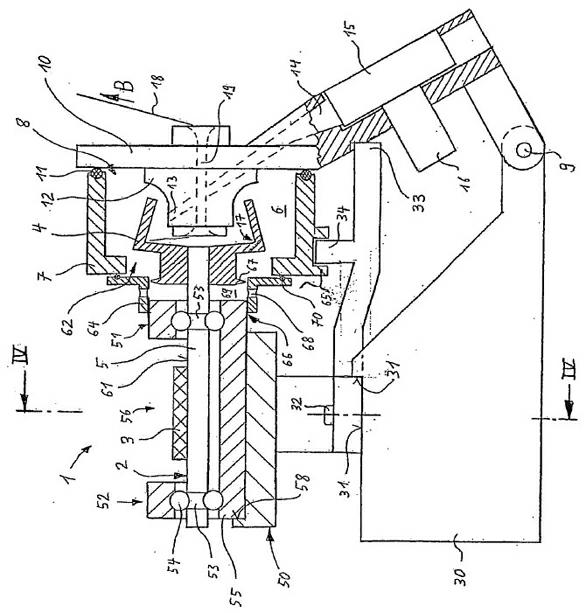

[0022] figure 1 and 2 The open textile machine 1 shown in contains a textile machine rotor 2 and a tangential drive belt 3 . The textile machine rotor 2 consists of a rotor disk 4 and a rotor shaft 5 . A tangential drive belt 3 runs through the machine in the direction of travel A and a rotor shaft 5 drives a plurality of textile machine rotors 2 arranged next to each other. During operation, the rotor disk 4 rotates in the vacuum chamber 6 of the rotor housing 7 . The negative pressure chamber 6 is connected to a negative pressure source in a manner not shown. The front opening 8 of the rotor housing 7 is closed with a cover element 10 which can be pivoted away about a pivot axis 9 for maintenance purposes. The ring seal 11 here provides a seal between the cover element 10 and the rotor housing 7 .

[0023] A substantially rotationally symmetrical exchangeable adapter 12 is arranged on the cover element 10 , which during operation partially protrudes into the interior of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com