Anti-friction bearing having bump-like projections which are attached to the bearing outer ring

A technology for rolling bearings and bearing outer rings, applied in ball bearings, bearing components, shafts and bearings, etc., can solve the problem of high cost, reduce sound radiation, and simplify the manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

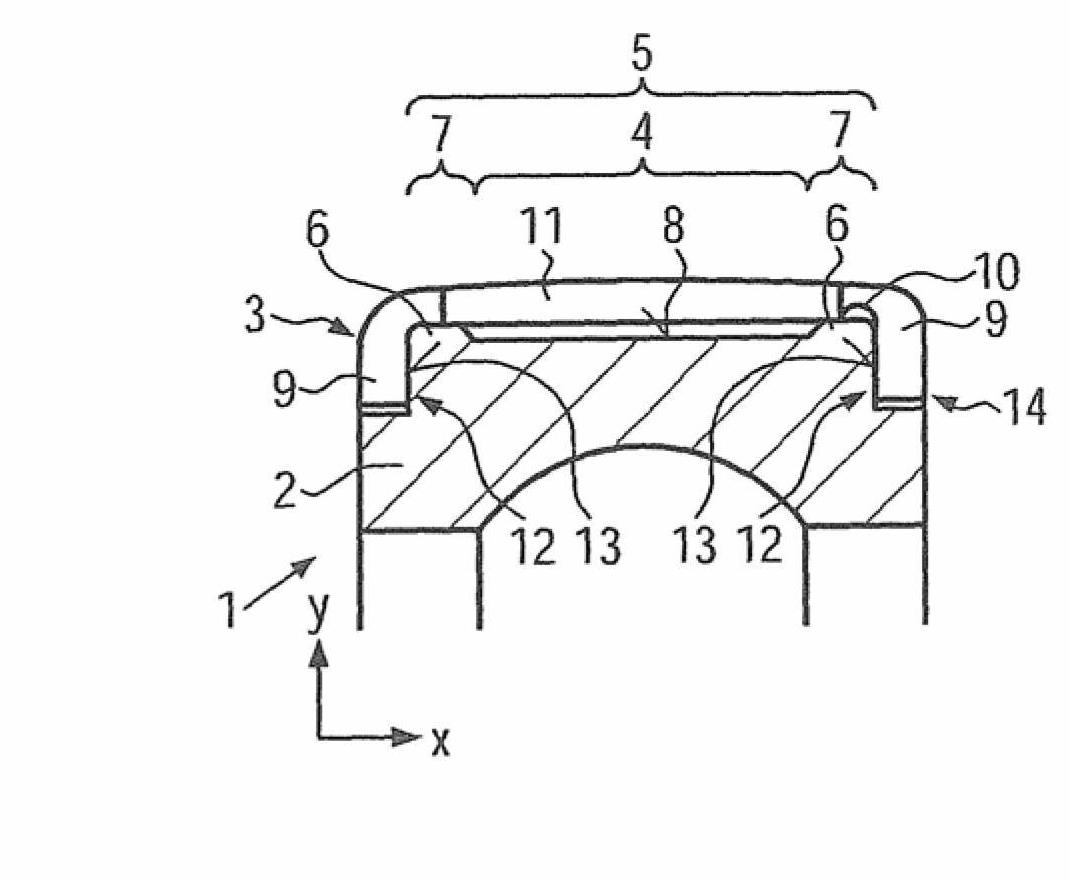

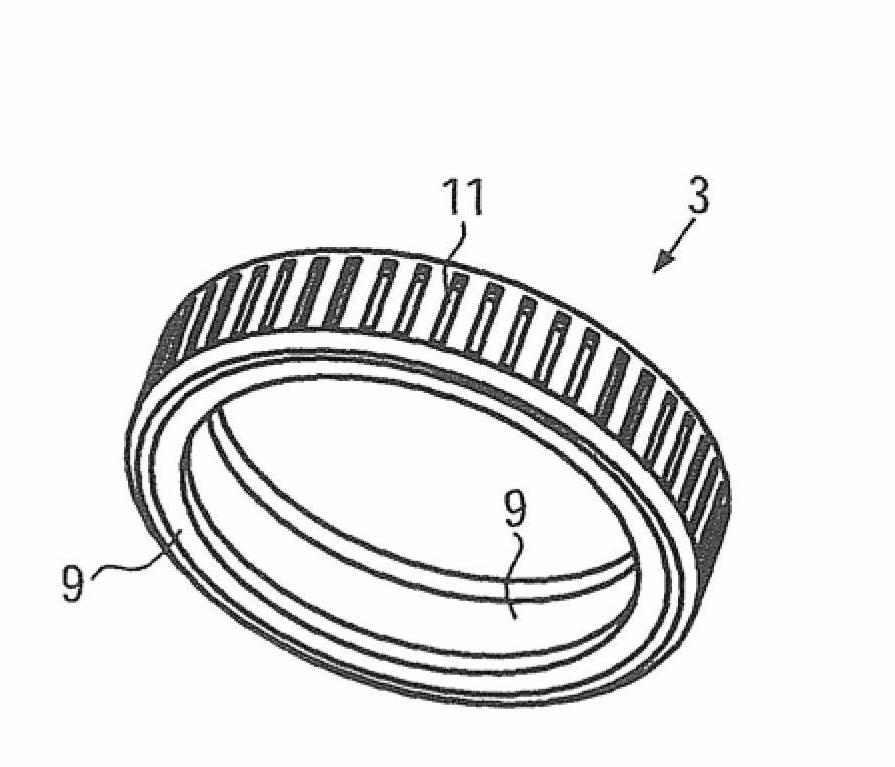

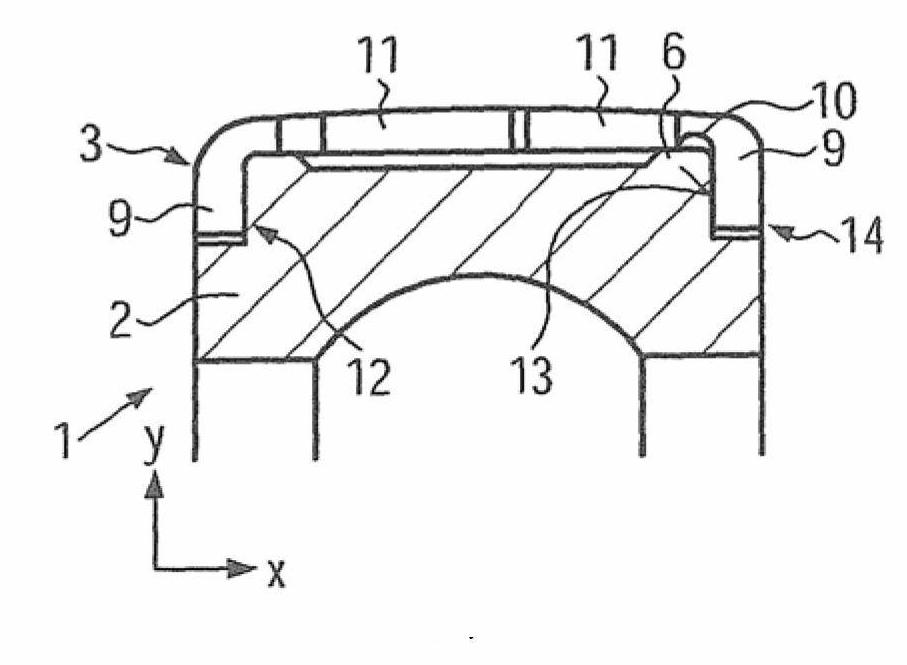

[0038]The drawings are merely schematic in nature and only facilitate the understanding of the invention. For the same elements, the same reference numbers are used.

[0039] figure 1 Shown in is a section of a first rolling bearing 1 according to the invention. The bearing inner ring is not shown, likewise the rolling bodies accommodated in the cage. Only the bearing outer ring 2 is shown. Also shown is a separating element 3 arranged radially on the outside of the bearing outer ring 2 . The separating element 3 has an abutment section 5 interrupted by a spring section 4 . The rest section 5 bears against the hump-shaped projection 6 . The boss 6 has a boss surface 7 . The axial length of the bead surface 7 plus the axial length of the spring section 4 equals the axial length of the bearing section 5 . Ultimately, therefore, the contact section 5 bears against the radial circumferential surface 8 of the bearing outer ring 2 only in the region of the bead surface 7 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com