High-voltage electrostatic absorptive film collector

A high-voltage electrostatic, adsorption-type technology, applied in the field of film shredders in field operations, can solve the problems of unclean picking, labor-intensive, labor-intensive, etc., and achieve the effect of novel and reasonable structure design, high efficiency and good operation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

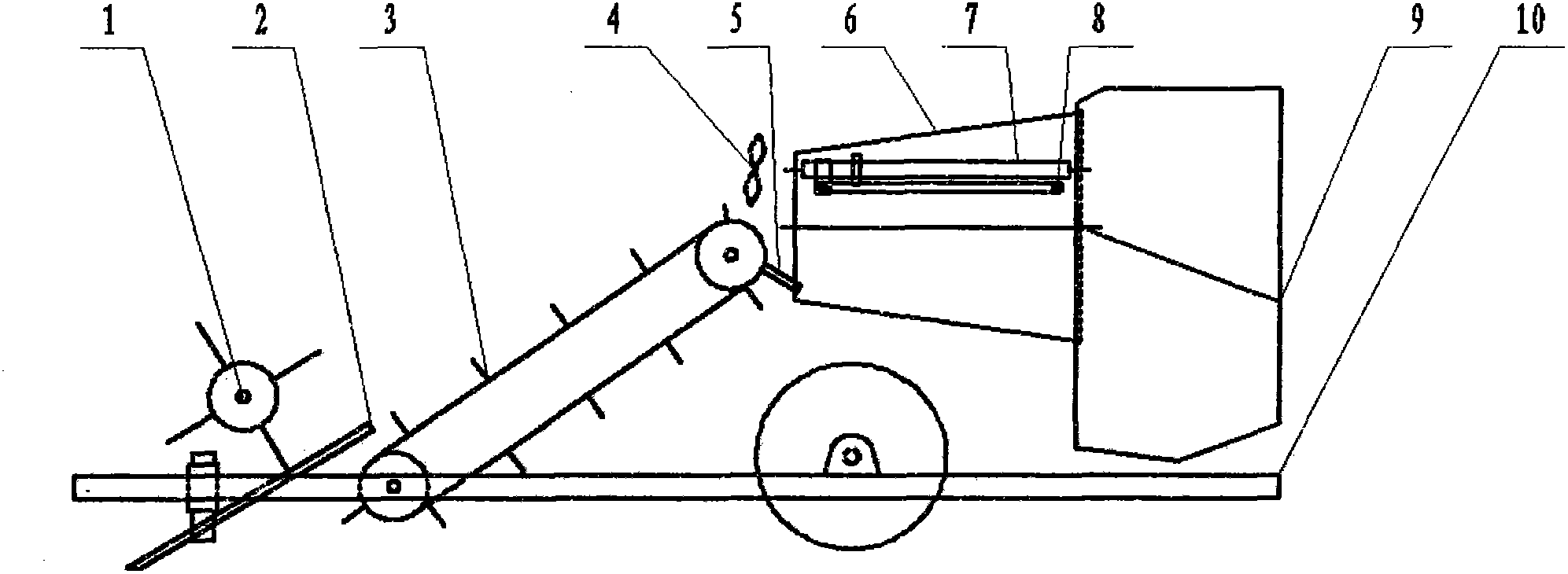

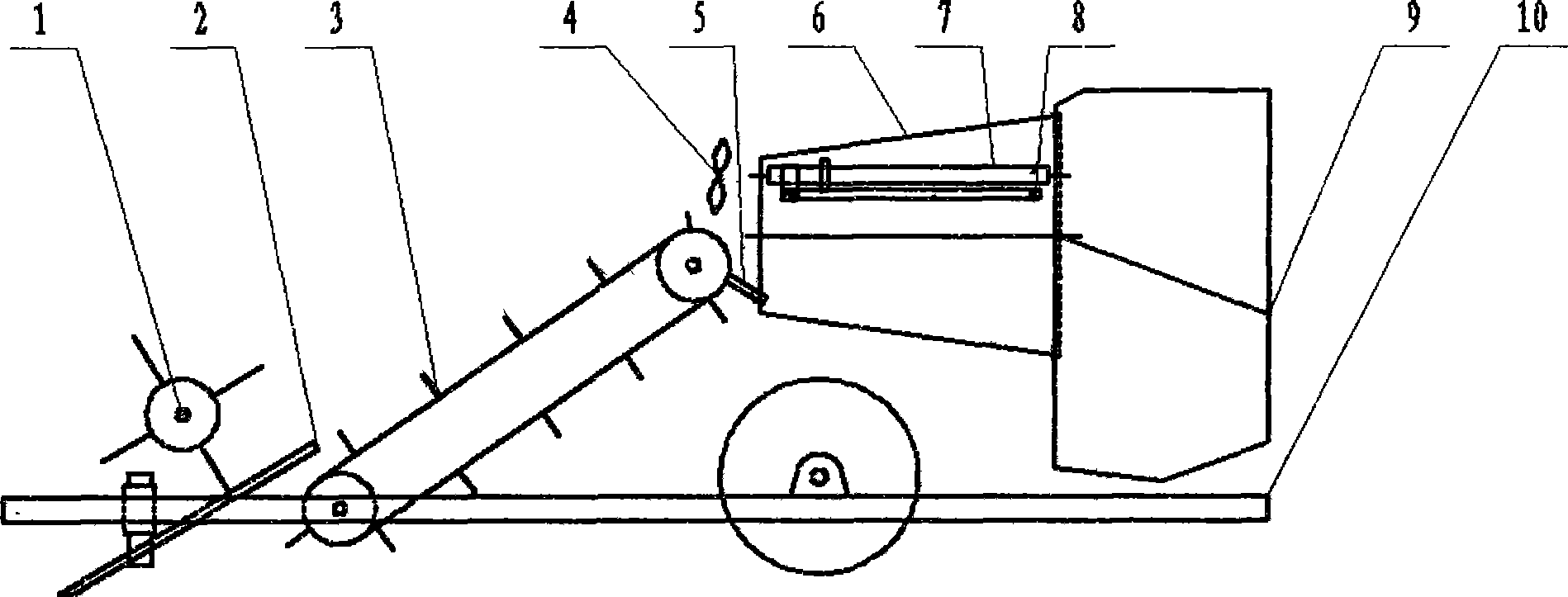

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A high-voltage electrostatic adsorption type film harvesting machine includes a frame 10, and a shovel-type stubble film harvesting assembly 2 and an endless rotary conveyor belt assembly 3 are sequentially assembled on the front side of the frame 10 from front to back. The rear end of the type stubble collecting assembly 2 is located above the front end of the endless rotary conveyor belt assembly 3, and is arranged in a staggered manner. The cage-type rotating drum 6 and the double-layer collecting box 9 are fixed and equipped with a high-voltage electrostatic adsorber 7 in the conical cage-type rotating drum 6, above the center line of the tapered cage-type rotating drum 6, and parallel to the center line. , the scraping film assembly 8 can be set on the high-voltage electrostatic adsorber 7 to move forward and backward, and the fan assembly 4 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com