Efficient semi-automatic film-receiving and rod-receiving integrated machine for arched shed, and control method thereof

A semi-automatic, all-in-one machine technology, applied in the directions of coiling strips, thin material handling, transportation and packaging, etc., can solve problems that affect the growth of crops, high labor intensity, large manpower and material resources, etc., to achieve autonomous operation of equipment and reduce labor costs Intensive, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

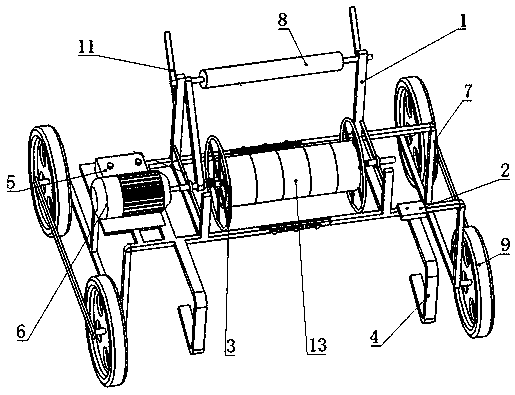

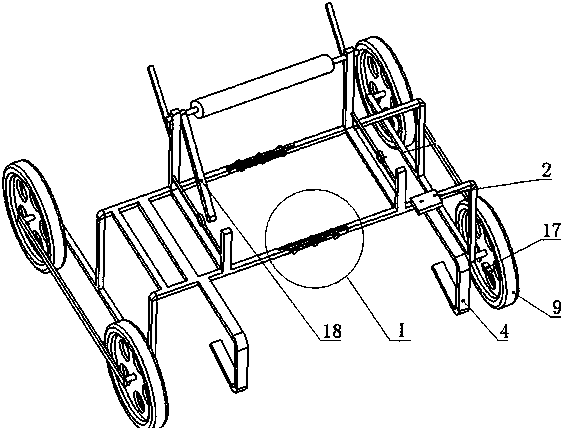

[0028] Such as figure 1 A high-efficiency semi-automatic shed retracting film and rod retracting machine is shown, including a vehicle frame 7 equipped with wheels 9, and a film rolling device 3 installed on the vehicle frame 7 and driven to rotate by a driving device 6. The vehicle frame 7 is also equipped with a rod retracting device 4 positioned at the rear of the film rolling device 3 . There are four wheels 9 arranged in a rectangle, and the direction of rotation of the wheels is consistent with the film-winding direction. For the convenience of control, the driving device in this embodiment is a servo motor.

[0029] The film rolling device 3 includes a central shaft 14 affixed to the output shaft of the servo motor, and a film rolling roller 13 sleeved on the central shaft 14, and the two ends of the film rolling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com