Automatic rice producing line

A production line and rice technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of manpower consumption, stomach infection, easy to affect the stomach, etc., and achieve the effect of improving processing efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

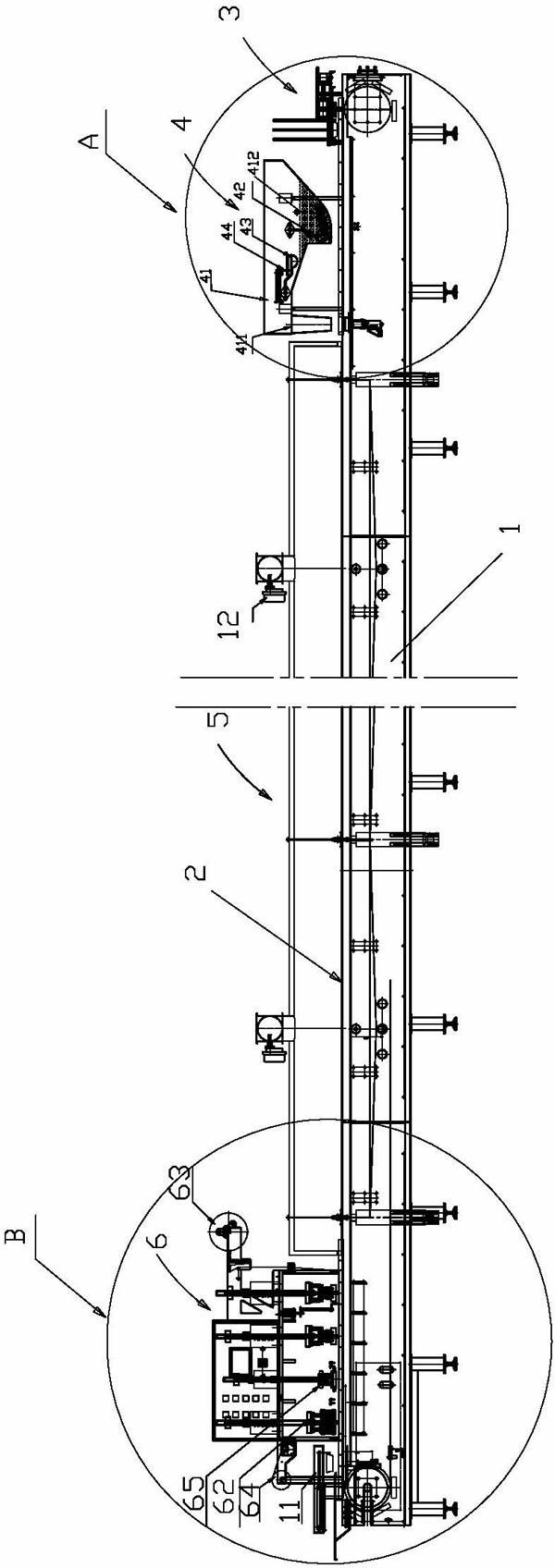

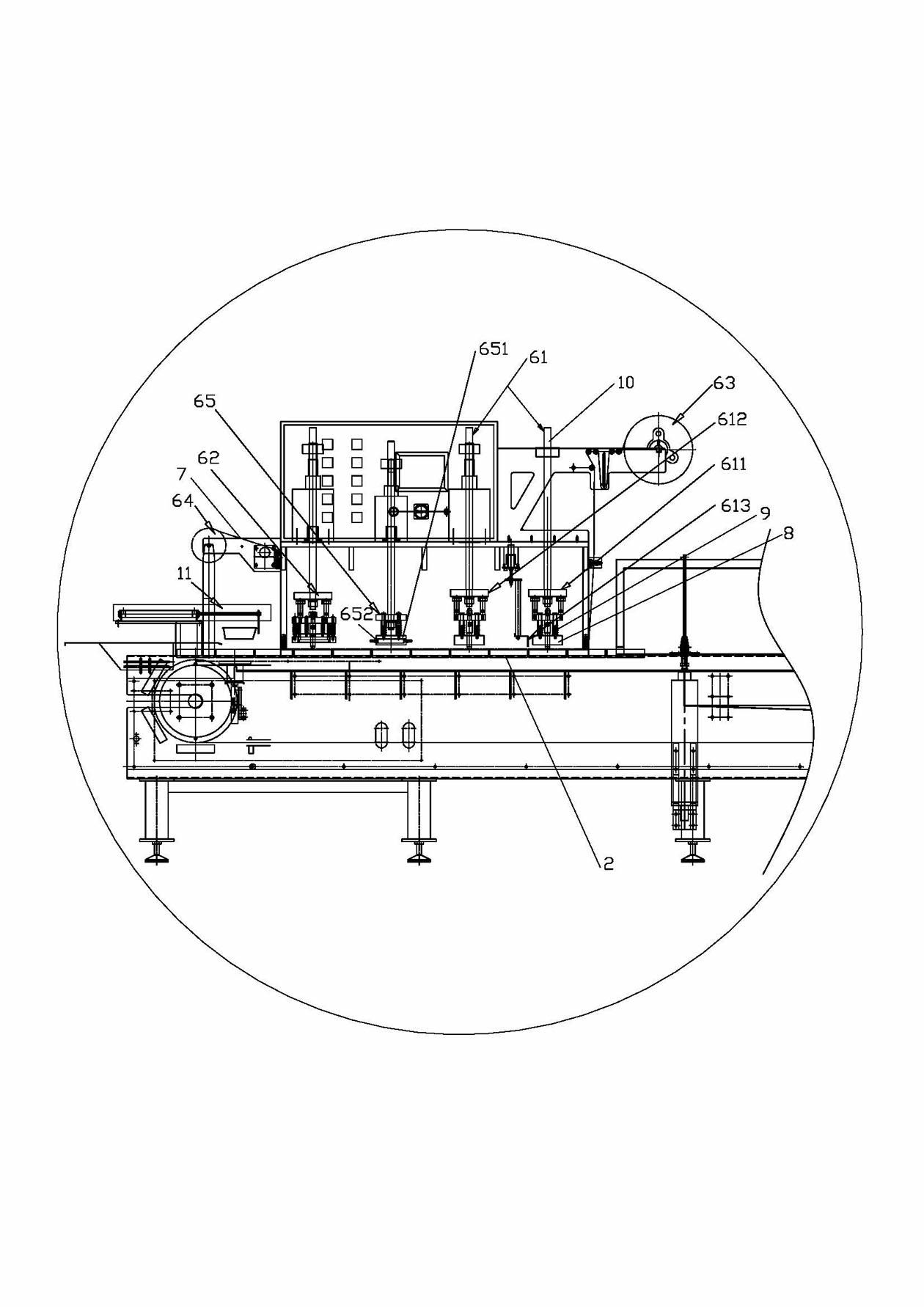

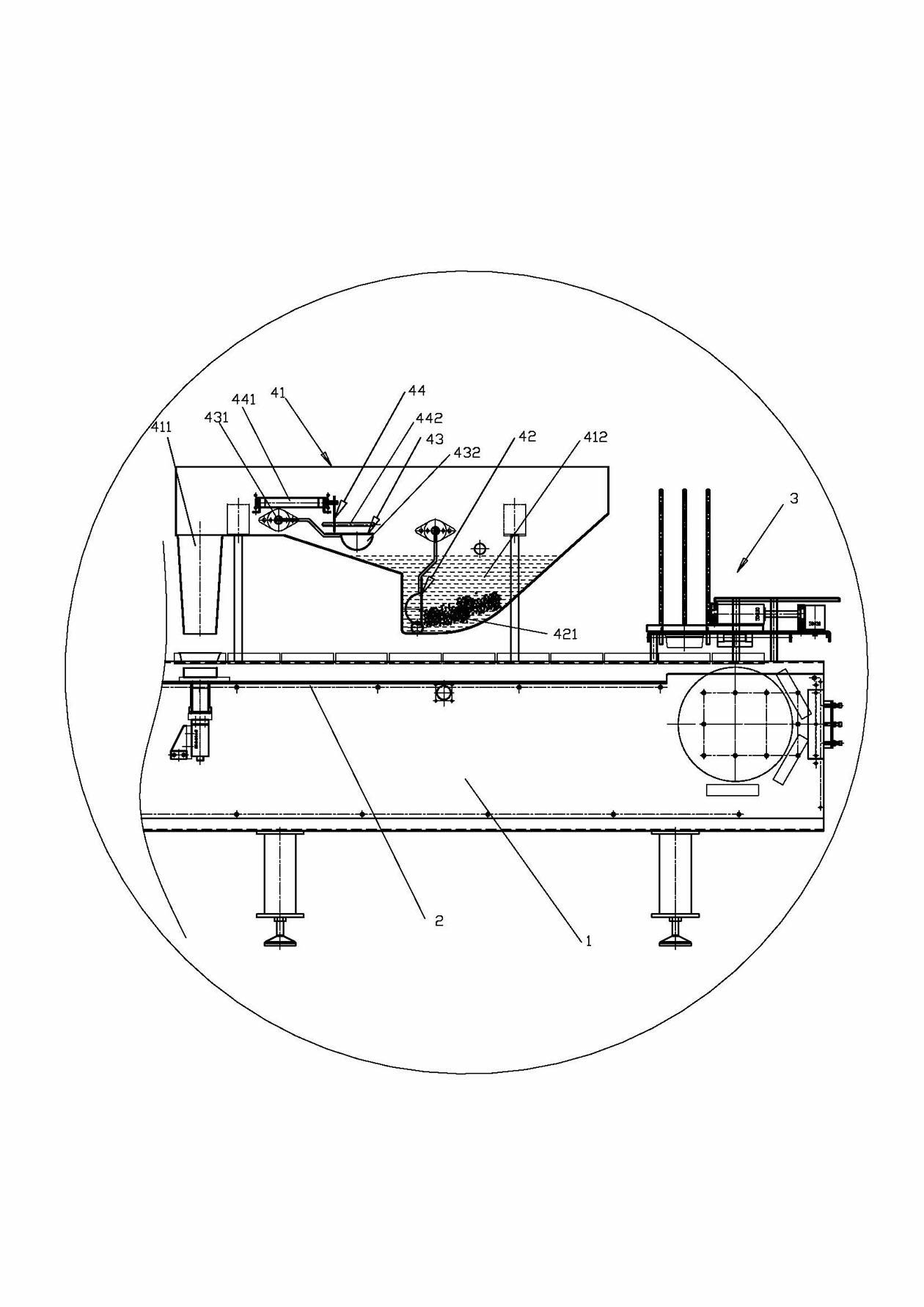

[0017] figure 1 , 2 Shown in and 3, the automated rice production line of the present invention comprises frame 1, endless conveyer belt 2, drop box device 3, quantitative filling device 4, steam box 5 and sealing trimming device 6, drop box device 3, quantitative filling The loading device 4, the steam box 5, and the sealing and trimming device 6 are arranged on the frame 1 from right to left. In this embodiment, the quantitative filling device 4 includes a filling body 41, a funnel 411 is provided at one end of the filling body 41, a rice storage tank 412 is provided at the other end, and a rotatable The 270-degree rice spoon 42 is provided with a quantitative spoon 43 that can rotate 180 degrees between the funnel 411 and the rice storage tank 412, and a scraper device 44 is provided on the quantitative spoon 43; the rotating shaft 431 of the quantitative spoon 43 reaches The distance of quantitative spoon 432 is identical to the distance from the axis of rotation 431 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com