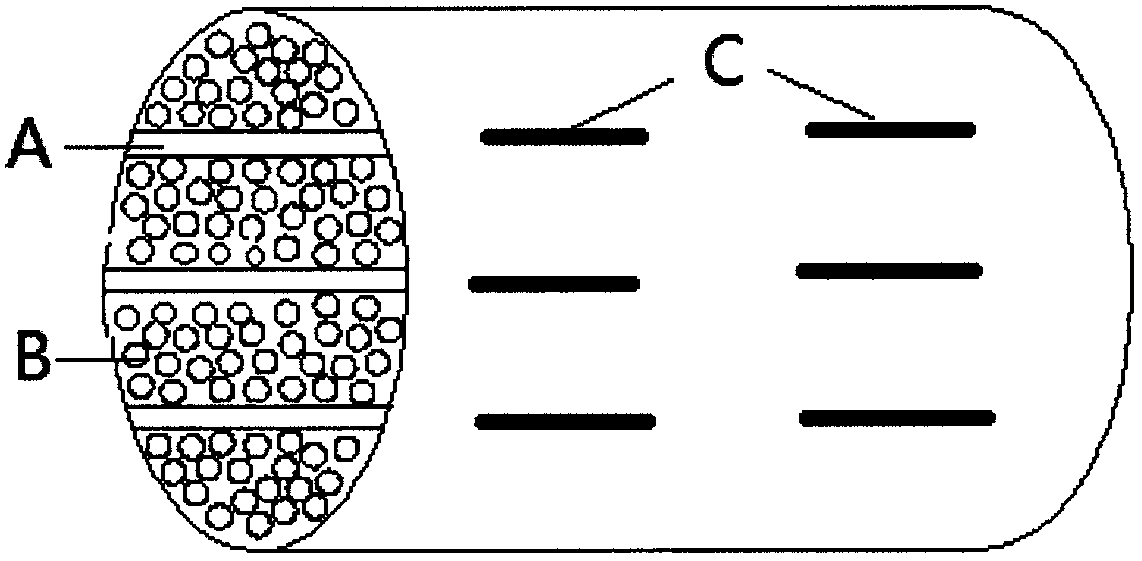

Ceramic membrane tube support and preparation method thereof

A technology of ceramic membrane tubes and supports, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of large liquid permeation resistance and long distance of liquid passing through the support, so as to reduce the permeation resistance , Improve the efficiency of permeation and separation, and reduce the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Chitosan (degree of deacetylation 84%, 10wt%), acetic acid (formulated into a 0.8vol% solution, 89.5wt%), glutaraldehyde (formulated into a 25wt% solution, 0.5wt%) were stirred on a magnetic stirrer 4h and mix evenly to prepare a premix.

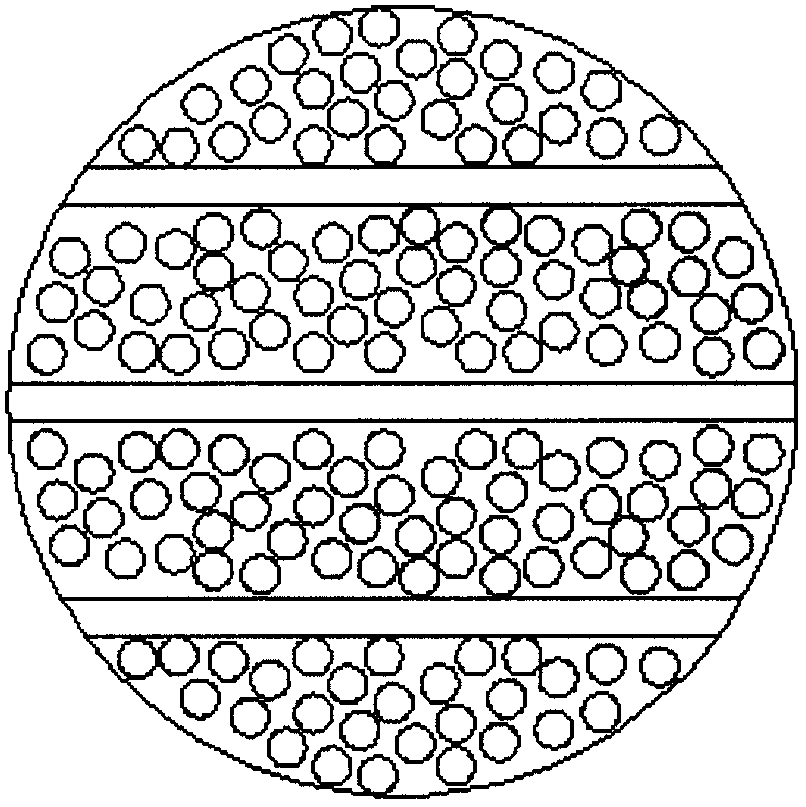

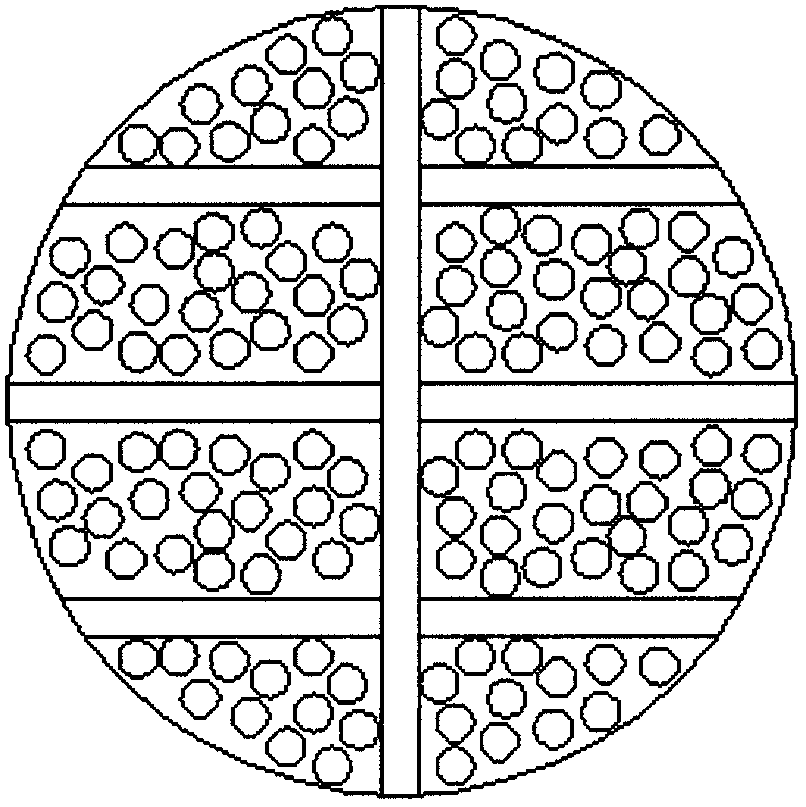

[0041] Mullite (40μm, 80wt%), starch (10wt%), methyl cellulose (molecular weight 50000, 10wt%) were dry ball milled for 4h and mixed evenly, and then the premix was added (the volume ratio of the mixed powder to the premix was 1 : 4), polyethylene glycol 4000 (0.5wt%) ball milled for 4h to make evenly dispersed mud. Then the mud is put into the mud mixer, and N, N, N'N'-tetramethylethylenediamine (0.1wt%) and hydrogen peroxide (10wt%) are added successively, and the relative vacuum is at 95%. The material is refined 6 times. The molding process of the porous ceramic membrane support body can be extrusion molding. The extrusion temperature is 10° C., the extrusion speed is 0.2 m / min, and the extrusion pressure is 6 MPa. Its length ...

Embodiment 2

[0043] Stir acrylamide (14.5wt%), tert-butanol (prepared as a 0.8vol% solution, 85wt%), N,N'-methylenebisacrylamide (0.5wt%) on a magnetic stirrer for 12h and mix uniformly into a premix.

[0044] ZrO 2 (10 μm, 88wt%), graphite powder (5wt%), polyvinyl alcohol (molecular weight is 220,000, 5wt%) dry ball milling 6h mixes evenly, then adds premix (the volume ratio of mixed powder and premix is 1: 1 ), BYK163 (1wt%) ball milled for 8h to make evenly dispersed mud. Then put the mud into the mud mixer, add N, N, N'N'-tetramethylethylenediamine (0.1wt%) and ammonium persulfate (8wt%) successively, and the relative vacuum is at 80%. The material is refined twice. The molding process of the porous ceramic membrane support body can be extrusion molding. The extrusion temperature is 50° C., the extrusion speed is 2 m / min, and the extrusion pressure is 6 MPa. Its length is 1m, diameter is 142mm, there are 800 channels inside, the diameter of the channel is 5mm, and the wall thick...

Embodiment 3

[0046] Acrylic acid (10wt%), distilled water (89wt%), and calcium iodate (1wt%) were stirred on a magnetic stirrer for 12 hours and mixed uniformly to prepare a premix.

[0047] Will Al 2 o 3 (5 μm, 91wt%), starch (3wt%), polyacrylamide (molecular weight 12 million, 6wt%) dry ball milling 8h and mix evenly, then add the premix (the volume ratio of the mixed powder and the premix is 1:3), Polyethyleneimine (PEI) (0.5wt%) was ball-milled for 6 hours to prepare a uniformly dispersed slurry. Then the slurry is put into the mud mixer, and N, N, N'N'-tetramethylethylenediamine (0.5wt%) and potassium persulfate (12wt%) are added successively, and the relative vacuum is at 90%. The material is refined 4 times. The molding process of the porous ceramic membrane support body can be extrusion molding. The extrusion temperature is 30° C., the extrusion speed is 1 m / min, and the extrusion pressure is 8 MPa. Its length is 1m, diameter is 142mm, there are 800 channels inside, the diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com