Colloid body conveying mechanism

A technology of conveying mechanism and colloid, which is applied to devices and coatings for coating liquid on the surface, can solve the problems of increased production cost, low production efficiency, increased production efficiency and product output, etc., to reduce waste of raw materials and save money. Labor force, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principle of the present invention will be described through embodiments. Other aspects, features and advantages of the present invention will become clear at a glance through the detailed description.

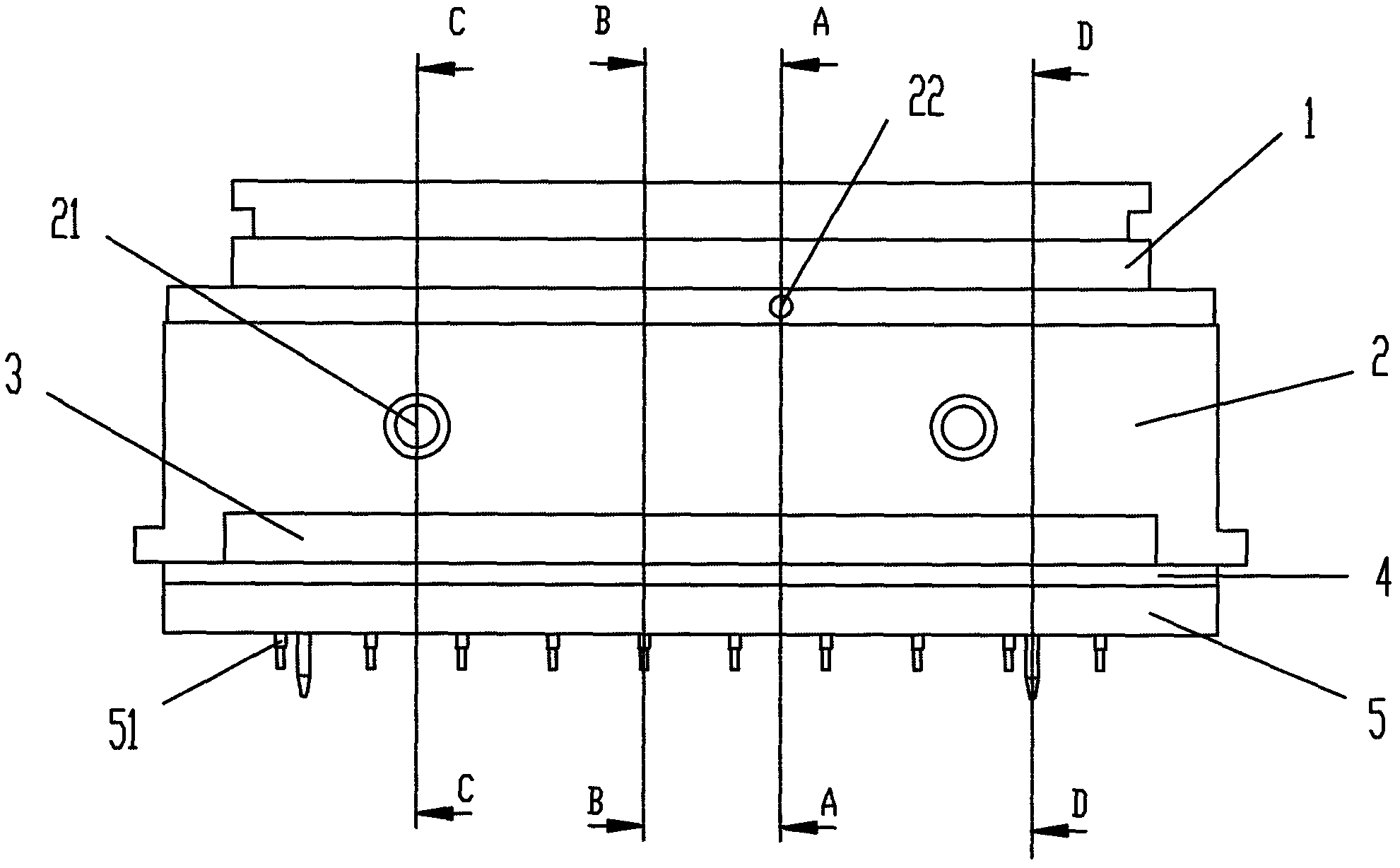

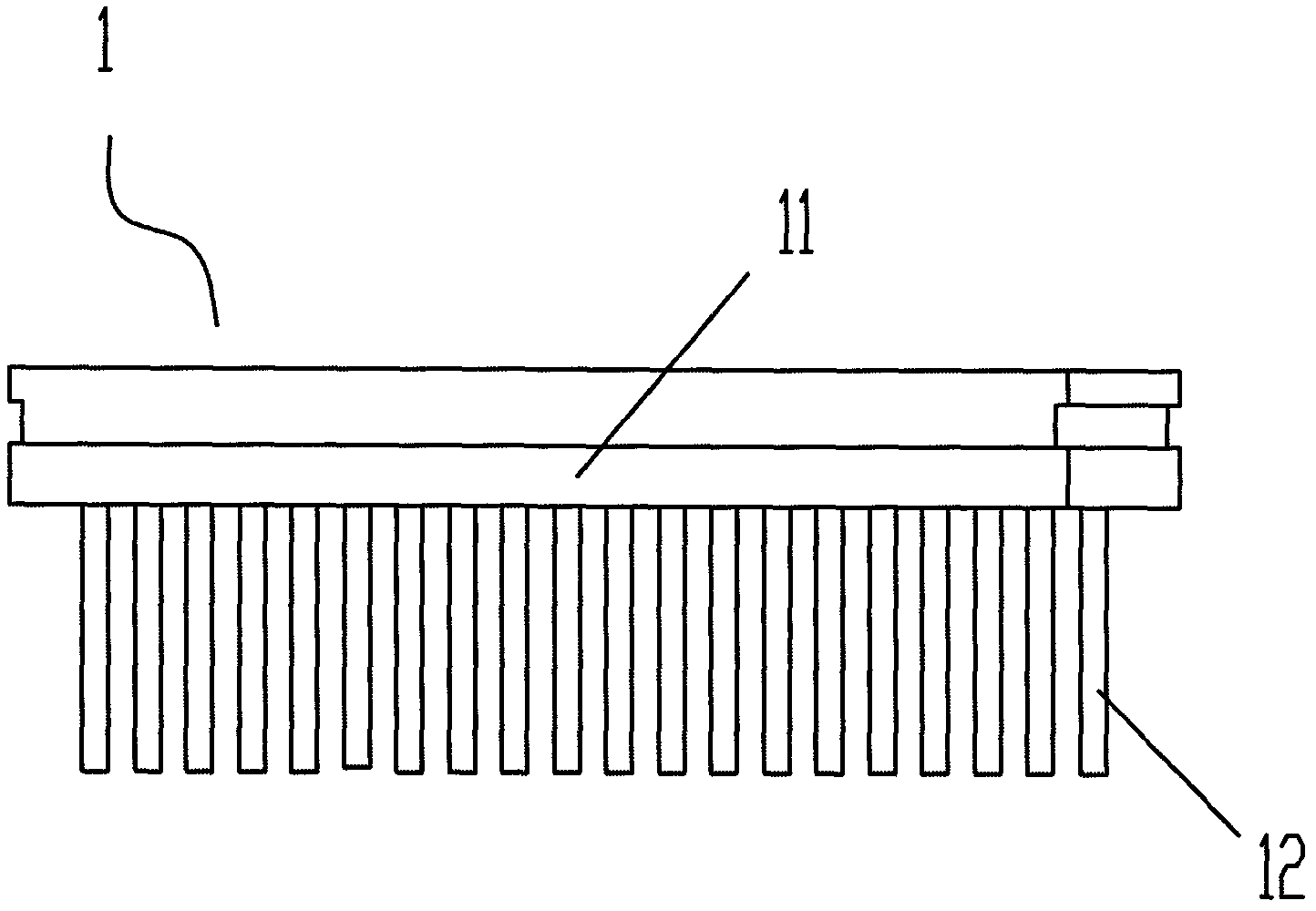

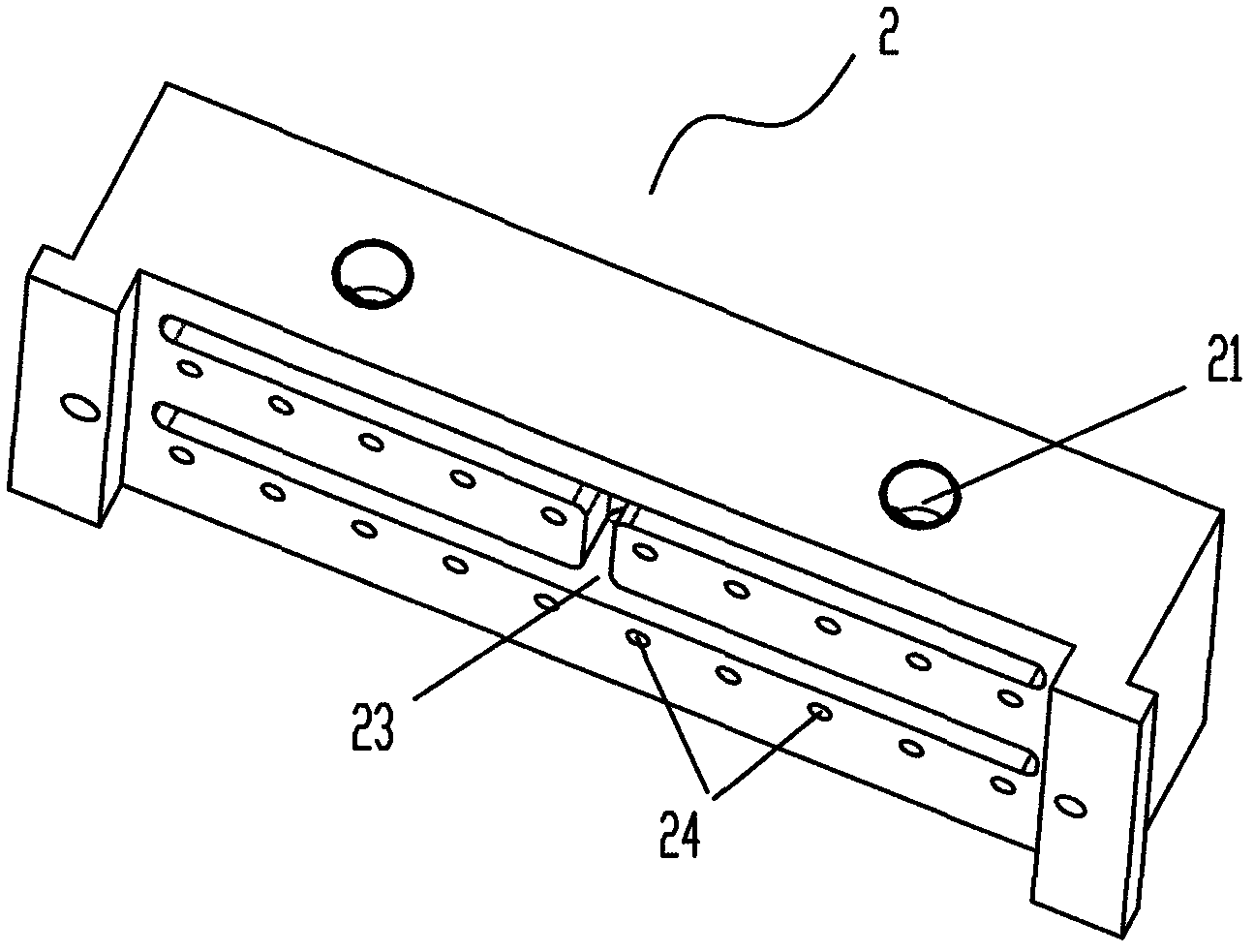

[0034] Such as Figure 1-11 As shown, a colloid conveying mechanism is used for conveying and injecting liquid colloid in the glue injection process of the glue injection machine. 5. A number of anti-leakage rubber rings to prevent colloid leakage and a cylinder unit control module for controlling a single cylinder unit. The colloid delivery mechanism body 2 includes a glue supply hole 21, a number of glue injection cylinders 24, and the glue supply The hole 21 is connected to the glue storage tank 23, and the separation plate 3 includes a separation plate conveying groove 31, a glue conveying hole 32 that is respectively correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com