High-strength hot nozzle flow guide sleeve

A diversion sleeve, high-strength technology, applied in the field of hot runner systems, can solve the problems of easy accumulation and carbonization of residual material, easy rupture of diversion sleeve, short service life, etc., to avoid material accumulation, low production cost, and easy processing convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

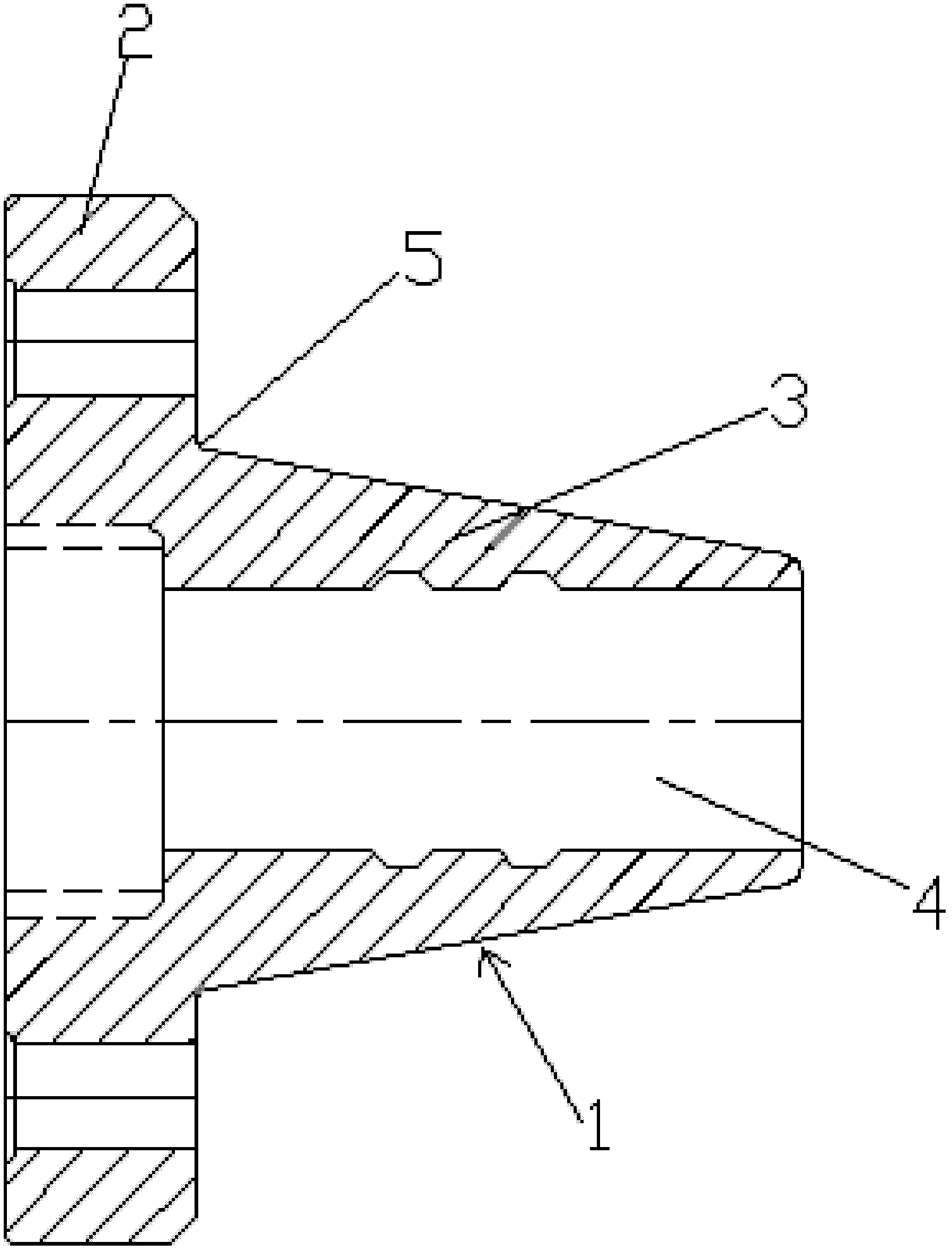

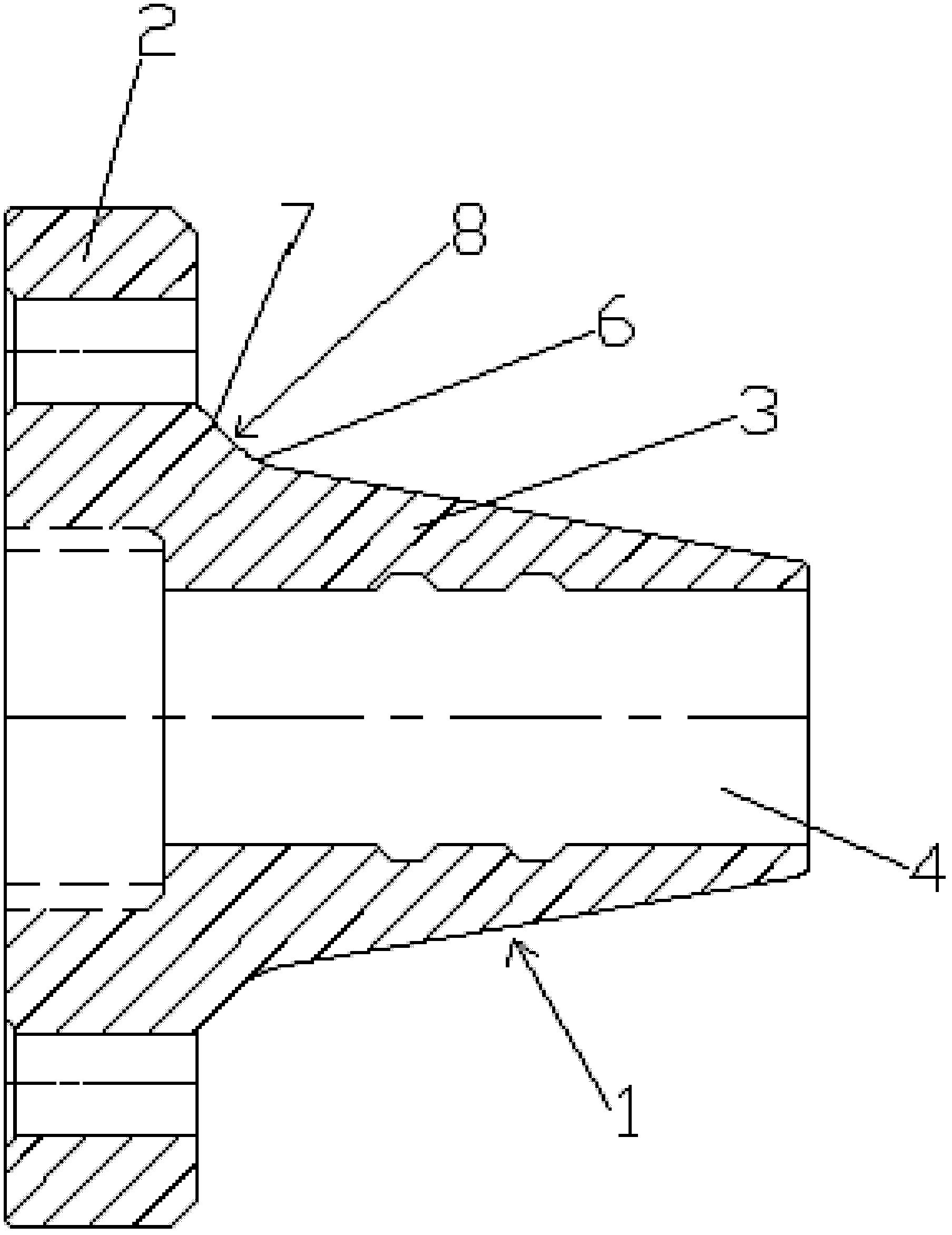

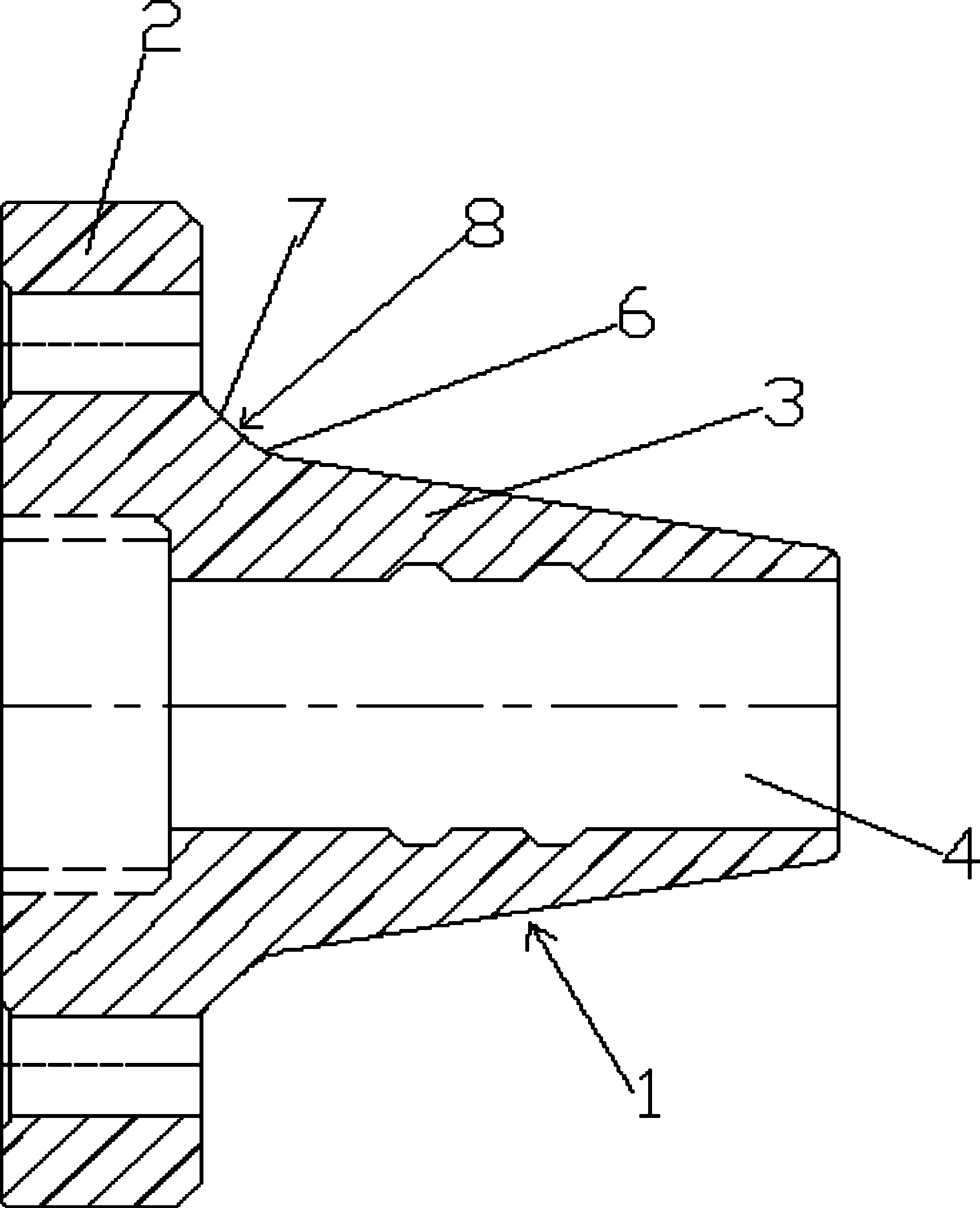

[0019] Such as figure 2 As shown, a high-strength hot nozzle guide sleeve, the guide sleeve 1 is composed of a circular frustum 2 and a conical frustum 3, and the center of the circular frustum 2 and the conical frustum 3 is provided with a communicating flow channel 4, which is characterized in that: In cross-section, the end of the frustum 3 is provided with a transition point 8 connected to the frustum 2; The ends are connected, and one end of the hypotenuse 7 is connected with the round platform 2 . The large R angle 6 is 3°. The wall thickness of the transition 8 is 3.71 mm.

[0020] Since the end of the frustum 3 is connected to the frustum 2 through the transition 8, the transition 8 is composed of a hypotenuse 7 and a large R angle 6 in cross-section. This structure makes the wall thickness of the transition 8 thicker. To 3.71mm, its strength is also strengthened, which effectively solves the problem of easy fracture due to stress concentration at the transition po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com