Automobile windscreen wiper assembly

A wiper and assembly technology, applied in the field of engineering components, can solve problems affecting driving safety, low cleaning efficiency, and unclean scraping, and achieve the effects of widening and clear vision, improving the effect of wiping rain, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

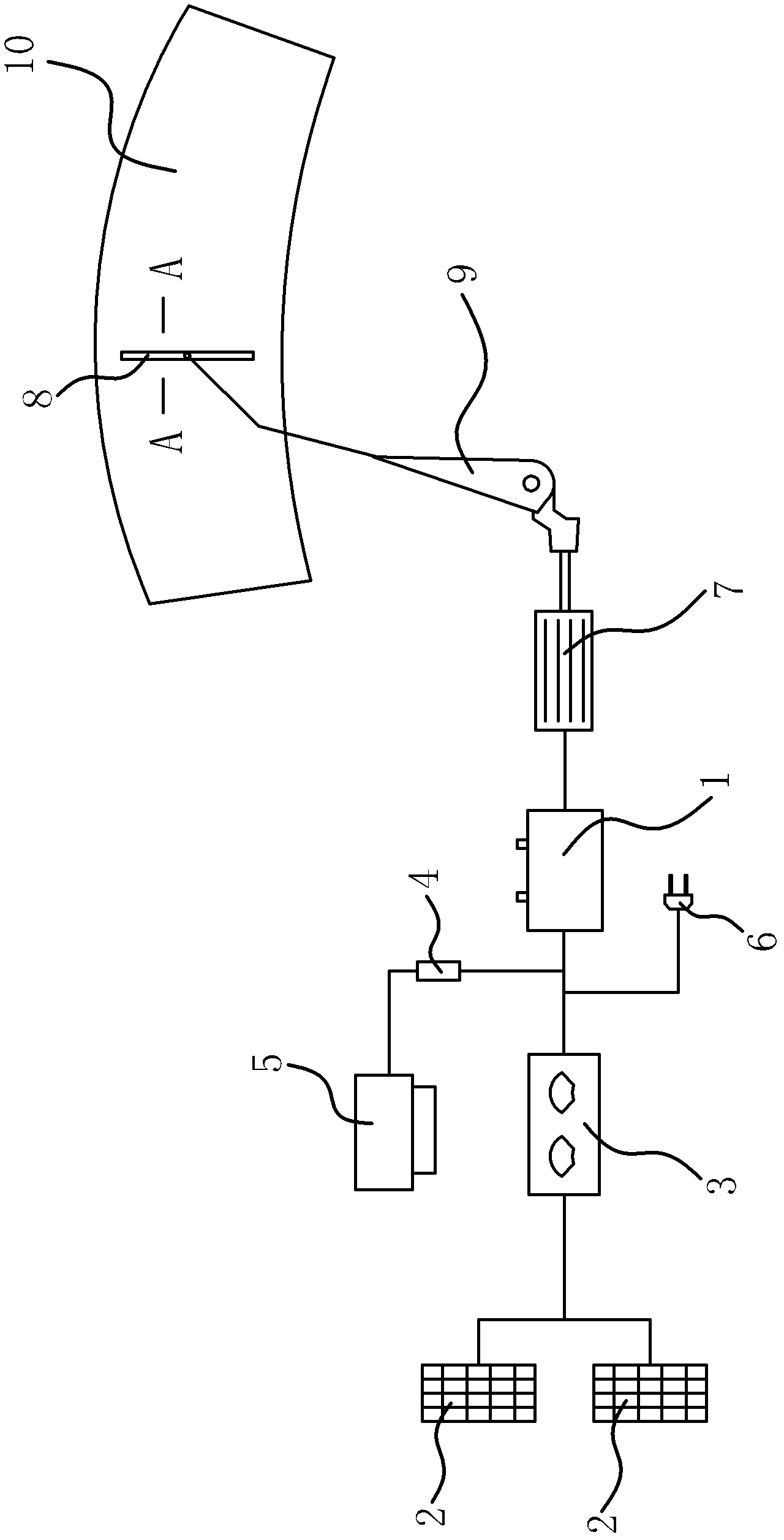

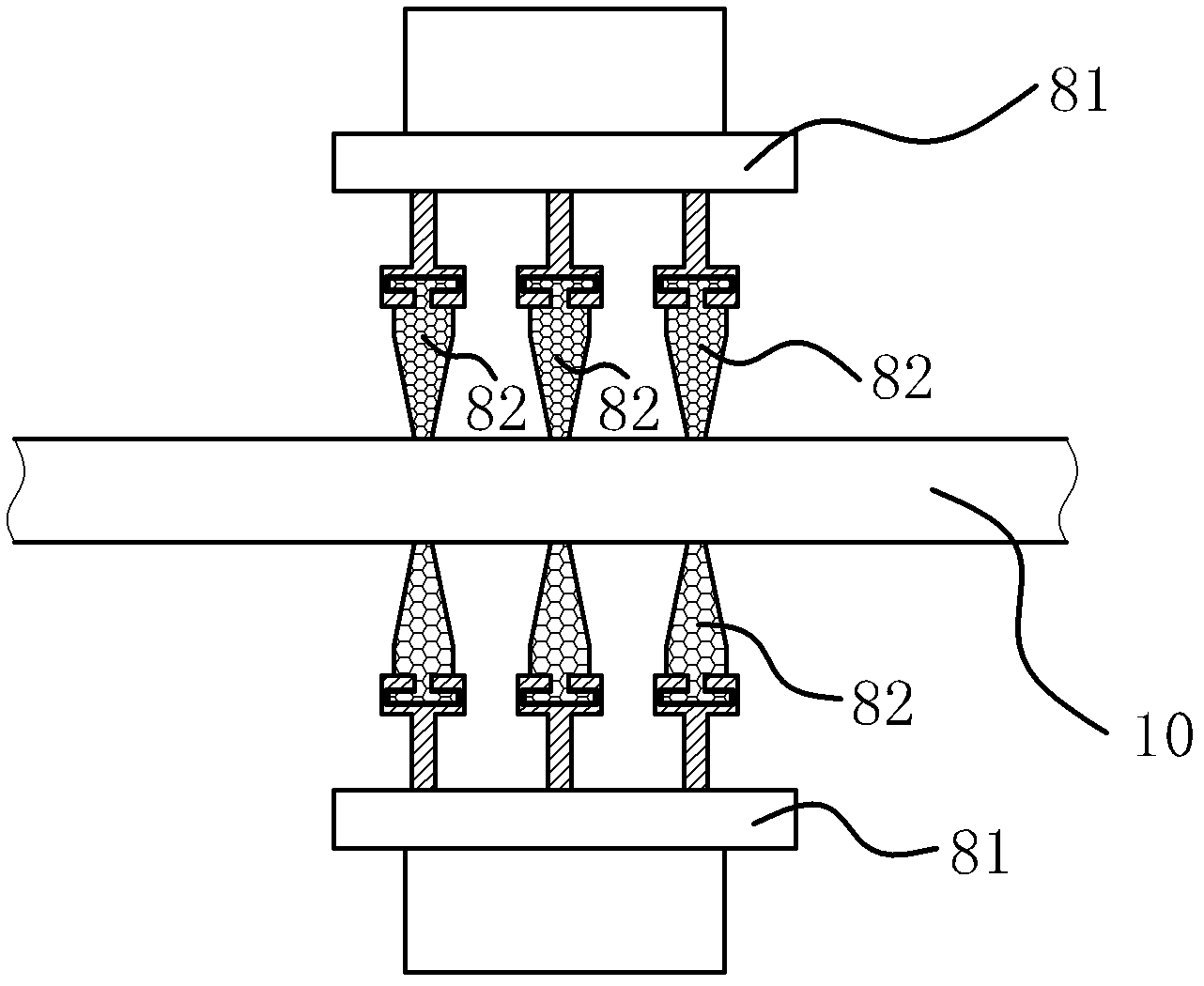

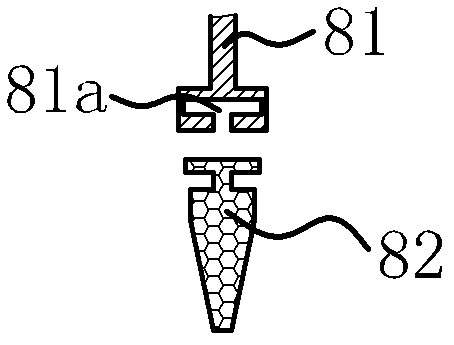

[0029] Such as figure 1 As shown, an automobile wiper assembly includes a drive motor 7 , a wiper blade assembly 8 , a battery 1 , a solar panel 2 and a transmission mechanism connecting the drive motor 7 and the wiper blade assembly 8 .

[0030] Specifically, the driving element in the assembly of the driving motor 7 , the battery 1 is electrically connected to the driving motor 7 ; the battery 1 supplies electric energy to the driving motor 7 . The storage battery 1 supplies power to the drive motor 7 solely, so that the stability of the power supply can be ensured and the drive motor 7 can work continuously for a long time.

[0031] The quantity of solar battery panel 2 is several pieces, and according to actual situat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com