Automobile flat wiper blade

A technology of wiper blades and automobiles, applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve problems such as uneven pressure, difficulty in replacement, noise, etc., to achieve extended service life, simple and clear structure, and overall performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

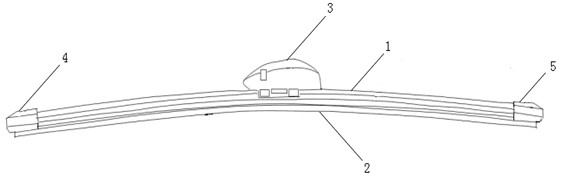

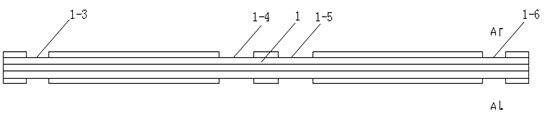

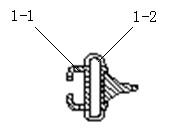

[0022] Referring to the drawings, this embodiment includes a sheath 1, a rubber strip 2, a steel sheet (not shown in the figure), a connector 3, a left end cap 4 and a right end cap 5, and the sheath 1 is provided with a chute 1- 1 and socket 1-2, the rubber strip 2 is installed in the chute 1-1 of the sheath 1, the steel sheet is installed in the socket 1-2 of the sheath 1, and the connector 3 passes through the steel The sheet is fixed in the middle of the sheath 1, and the left end cap 4 and the right end cap 5 are respectively fixed at both ends of the sheath 1. The jack 1-2 is a through hole.

[0023] A punching groove II1-4 and a punching groove III1-5 are provided in the middle of the sheath 1, and a fixing groove 3-1 matching the punching groove II1-4 and the punching groove III1-5 is provided on the connector 3.

[0024] When the steel sheet ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap