Track type multi-station chemical tempering furnace

A chemical tempering and multi-station technology, applied in glass tempering, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of difficult preheating chamber door manufacturing, broken steel wire rope 4, large heat dissipation loss, etc., and achieve low efficiency improvement , Improve speed and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

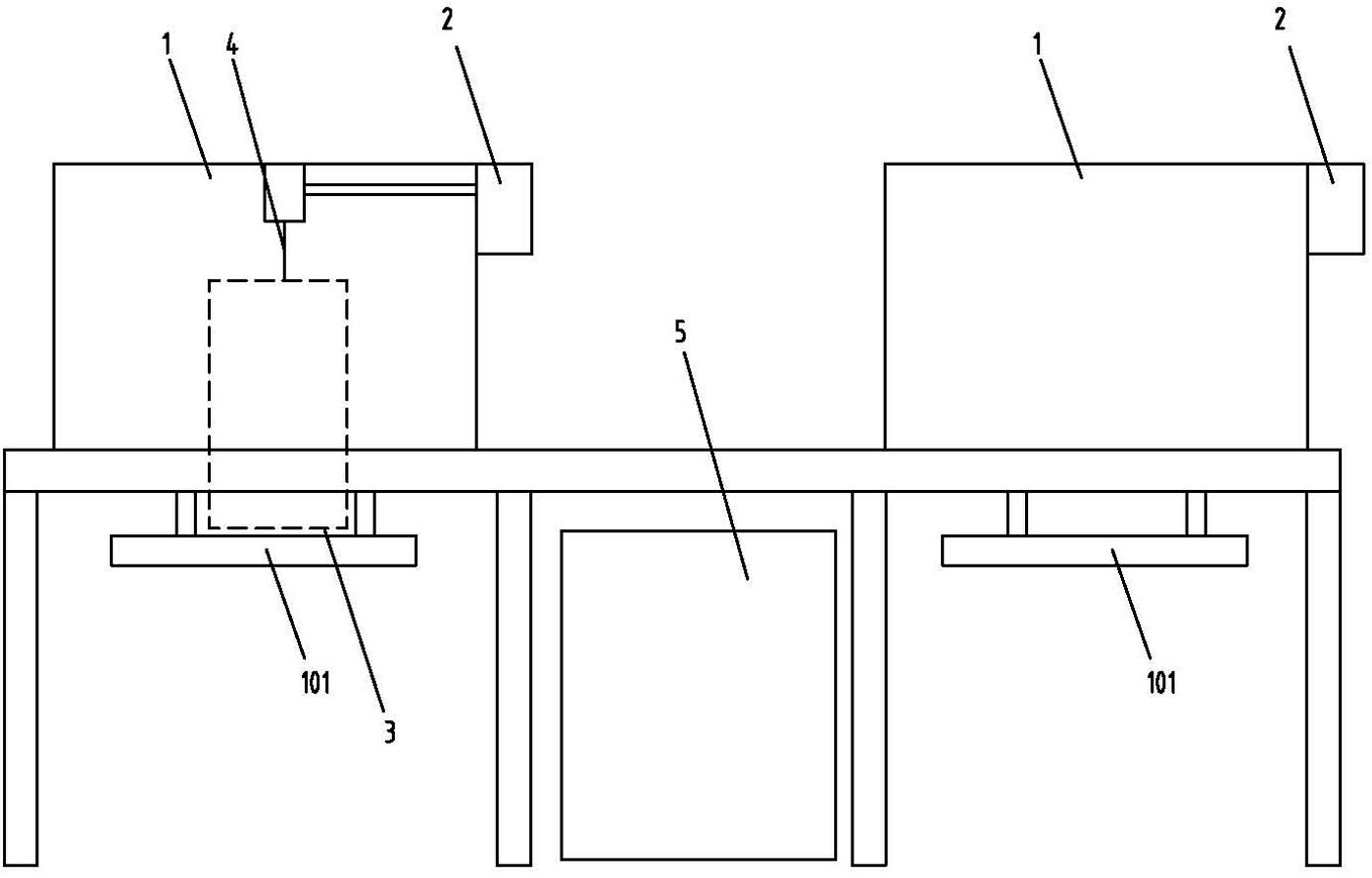

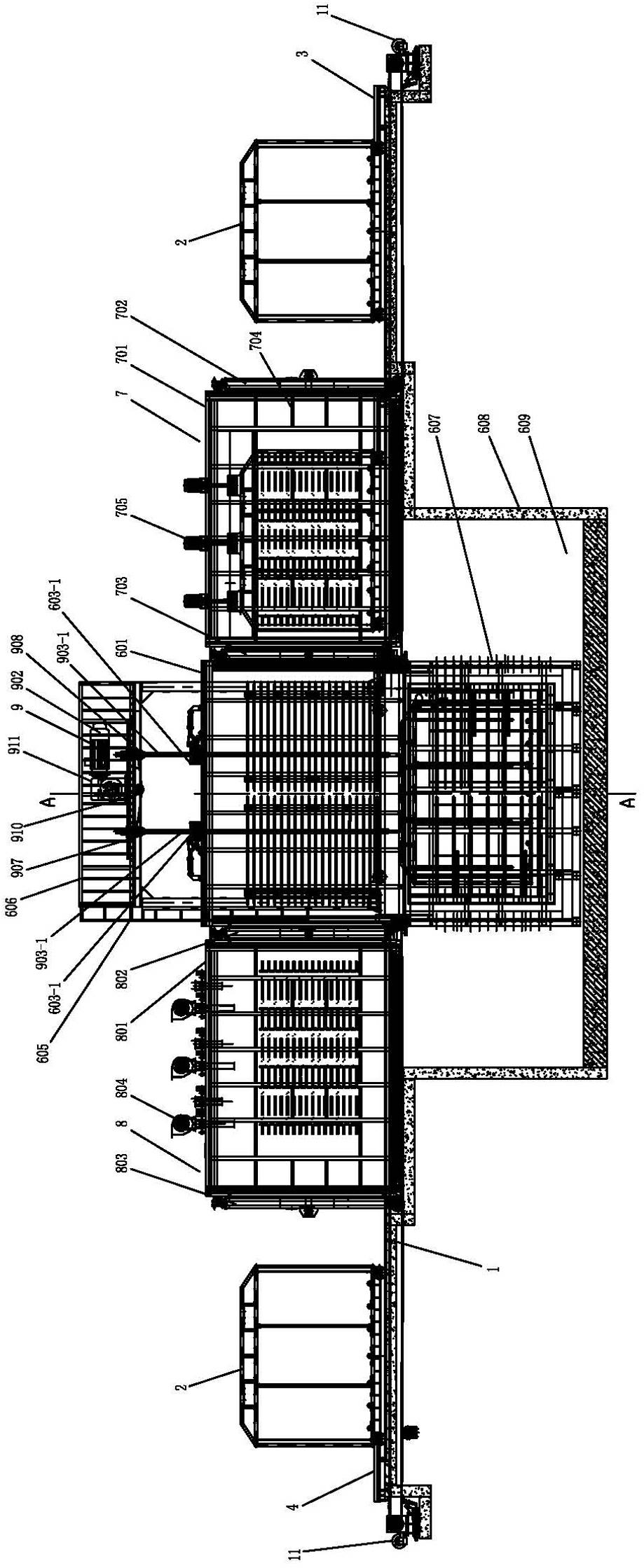

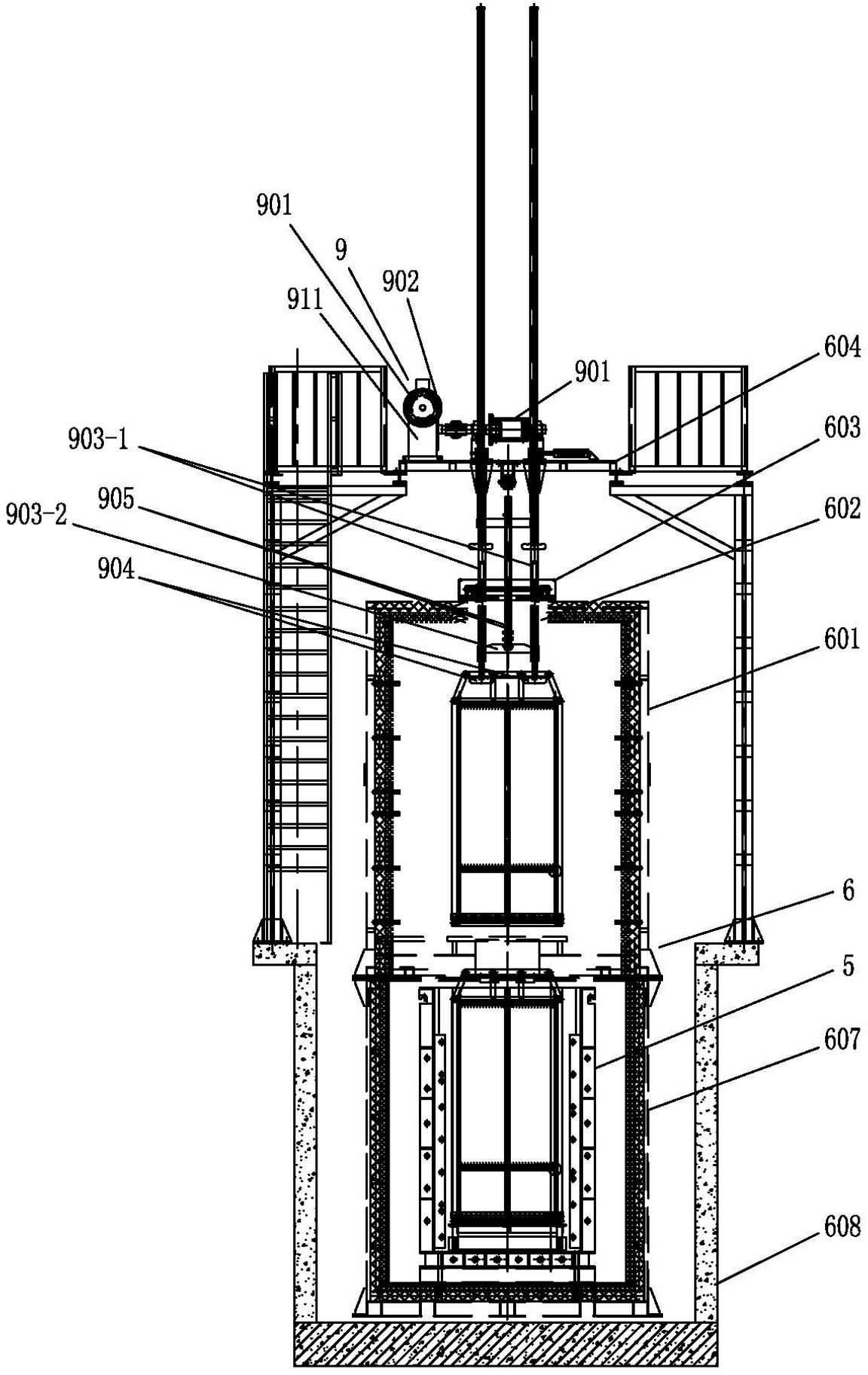

[0030] Such as Figure 2 to Figure 5 As shown, a track-type multi-station chemical tempering furnace is characterized in that it includes a horizontal guide rail 1, an intermediate main tempering chamber 6, and front and rear trolleys 3 carrying glass frames 2 installed on the horizontal guide rail 1, 4. The middle main tempering chamber 6 is composed of upper and lower tempering boxes 601 and 607 extending along the horizontal guide rail 1 up and down. The front and rear sides are respectively provided with a preheating furnace body 7 and an annealing furnace body 8, and a glass shelf lifting device 9 is installed on the top of the upper toughened box body 601;

[0031] The preheating furnace body 7 is composed of a preheating box body 701 and front and rear preheating furnace doors 702, 703. The rear preheating furnace door 703 communicates with one ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap