Laser heat treatment hardening method for steel pipe cast iron roll surface

A technology of laser heat treatment and cast iron rolls, which is applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve unsolved problems such as laser surface strengthening of seamless steel tube rolls, affecting the service life of rolls, and prone to cracks on the surface, etc., to achieve shortening Processing time, guaranteed hardness and wear resistance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Laser Surface Hardening of Infinitely Chilled Cast Iron Rolls

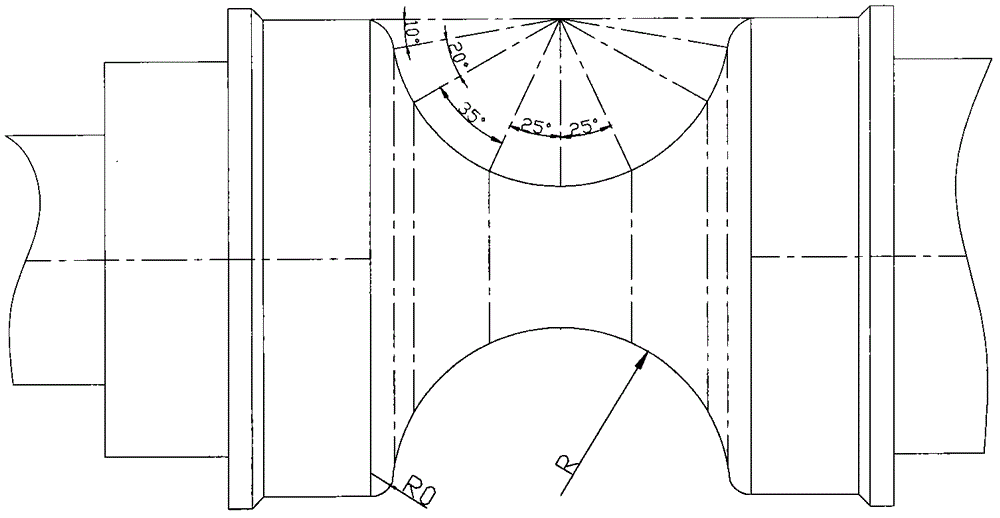

[0028] First, take the infinite chilled roll used for rolling seamless steel pipe as the processing object, the central arc radius R=71.74mm, according to figure 1 The display is divided into 7 areas, of which the arc of area I is 10 degrees, the arc of area II is 20 degrees, the arc of area III is 35 degrees, the arc of area IV is 50 degrees, the arc of area V is 35 degrees, the arc of area VI is 20 degrees, and the arc of area VII is 10 degrees .

[0029] Secondly, install the roll to be treated on the workbench, use sandpaper or hand-held grinding wheel to derust the working surface of the roll, and clean the working surface of the roll with acetone until the surface is smooth and free of oil; The light-absorbing paint is evenly sprayed on the surface of the roll, and the thickness of the sprayed layer of the light-absorbing paint is about 0.05mm.

[0030] Then, the surface of the roll is laser hardene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com