Excavating and cable-paving integrated machine

An all-in-one machine and cable laying technology, which can be used in earthmoving machines/shovels, construction, etc., can solve the problems of manpower consumption, difficult to restore landforms, laborious and other problems, and achieve a simple and compact structure, easy coordination and control, and easy installation and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

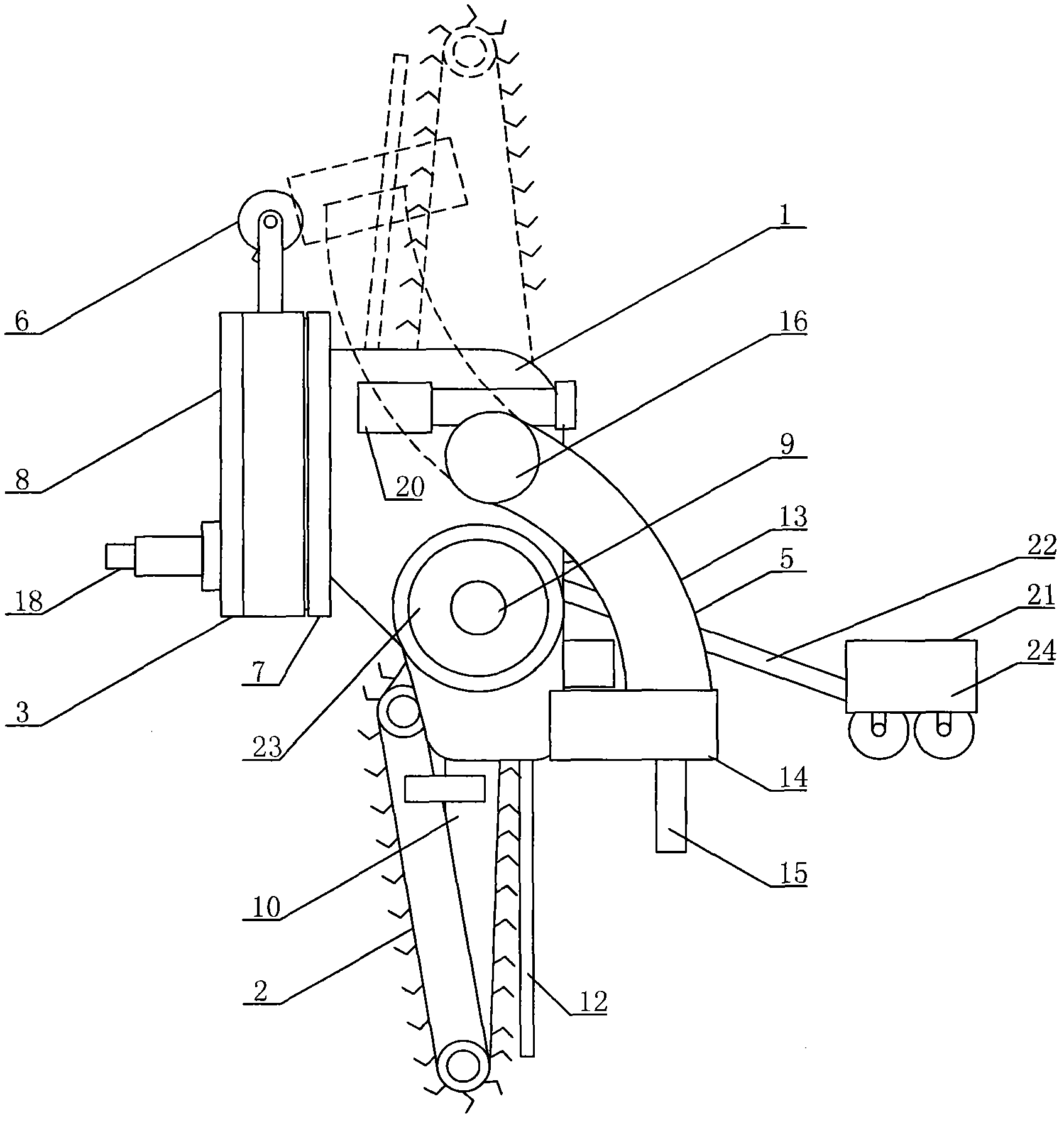

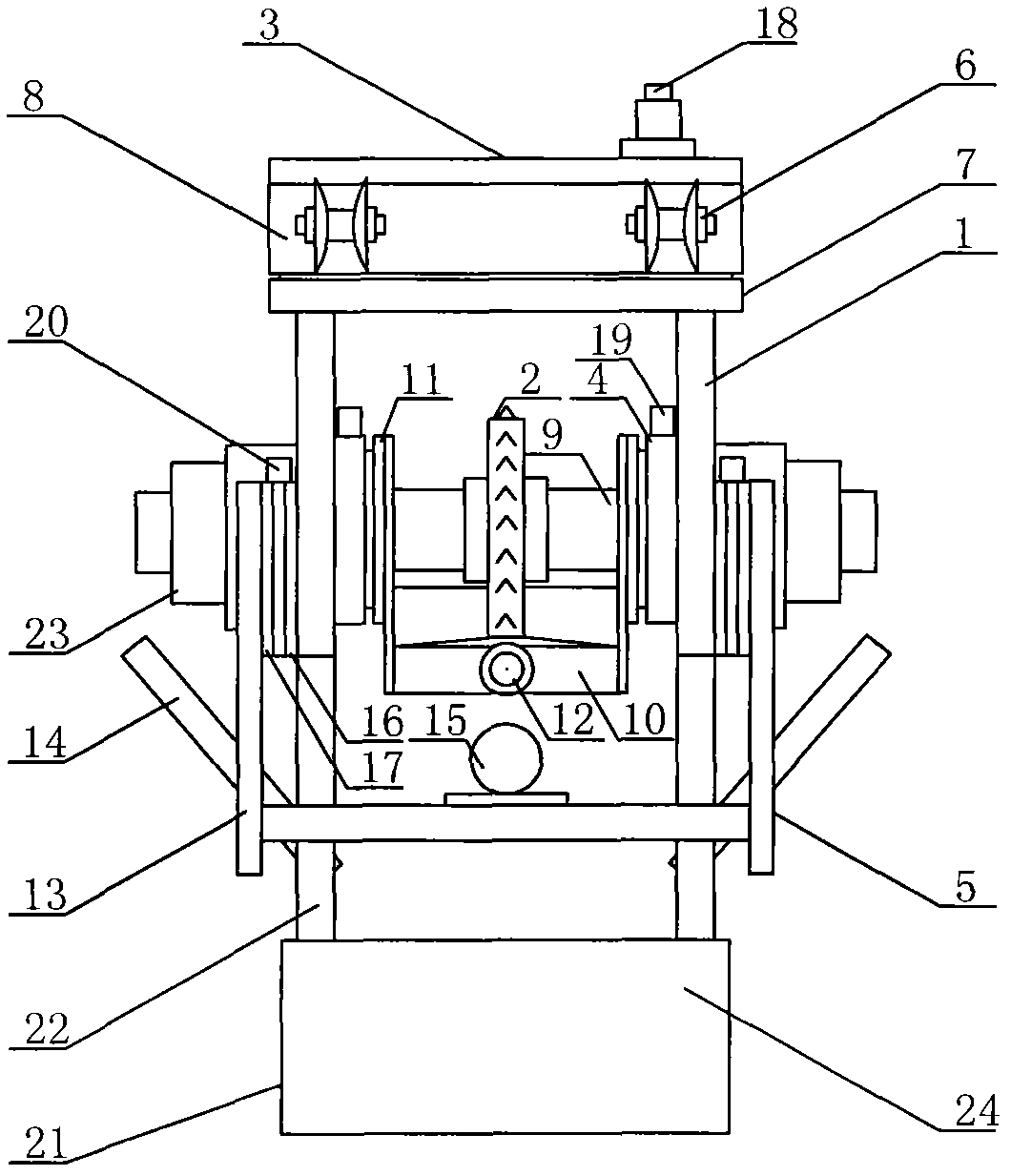

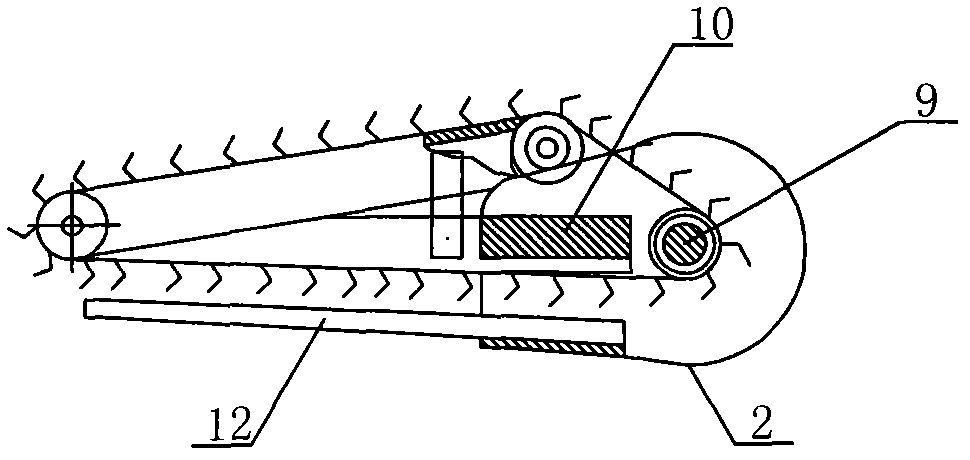

[0018] Specific implementation: such as Figure 1 to Figure 4 As shown, the digging and laying cable integrated machine includes a drive base 1, a knife chain opener 2, a balance turntable drive bearing 3, two take-off and landing turntable drive bearings 4, a backfiller 5, and a cable conveying guide wheel 6. And the traction vibration roller 21, a balance turntable drive bearing 3 is provided in the front of the drive base 1, and the balance turntable drive bearing slewing support 7 is fixedly connected to the front of the drive base 1. The balance turntable drive bearing motor 18 is a hydraulic motor, and the balance turntable The driving bearing 3 plays a role in adjusting the balance of the excavating and laying cable integrated machine. When the tractor is walking up and down, the balance turntable drive bearing 3 keeps the knife chain opener 2 always balanced and vertical; on the top of the balance turntable drive bearing housing 8 There are cable conveying guide wheels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com