Aluminum alloy floor

A technology of aluminum alloy and floor, applied in the field of aluminum alloy floor, can solve the problems of high heating power, low thermal conductivity, high cost, etc., and achieve the effect of reducing space temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

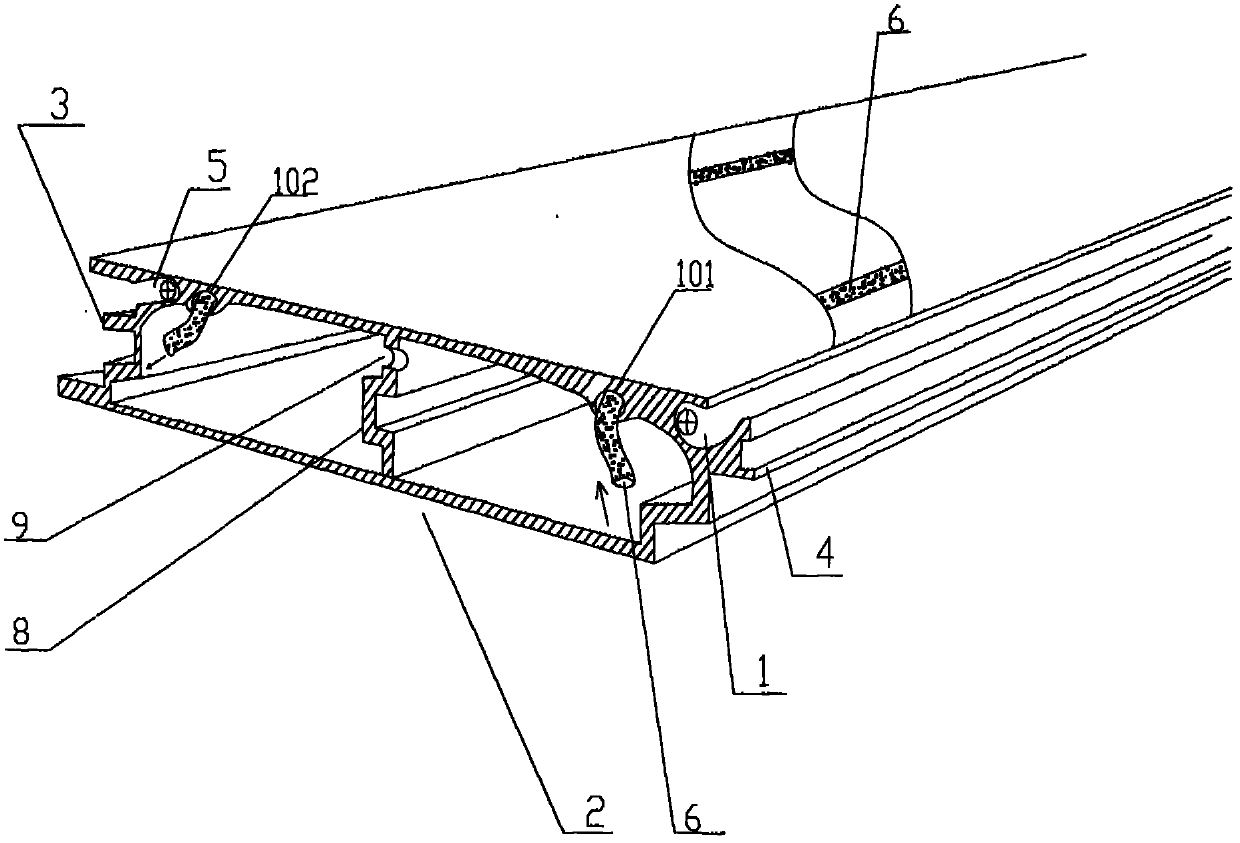

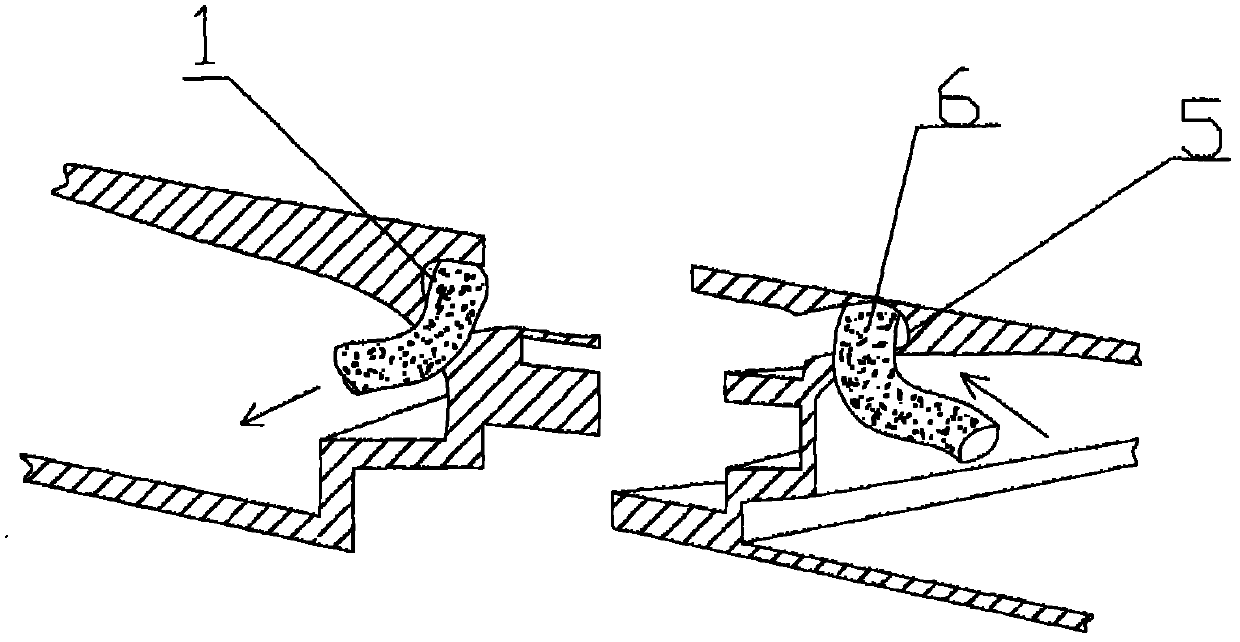

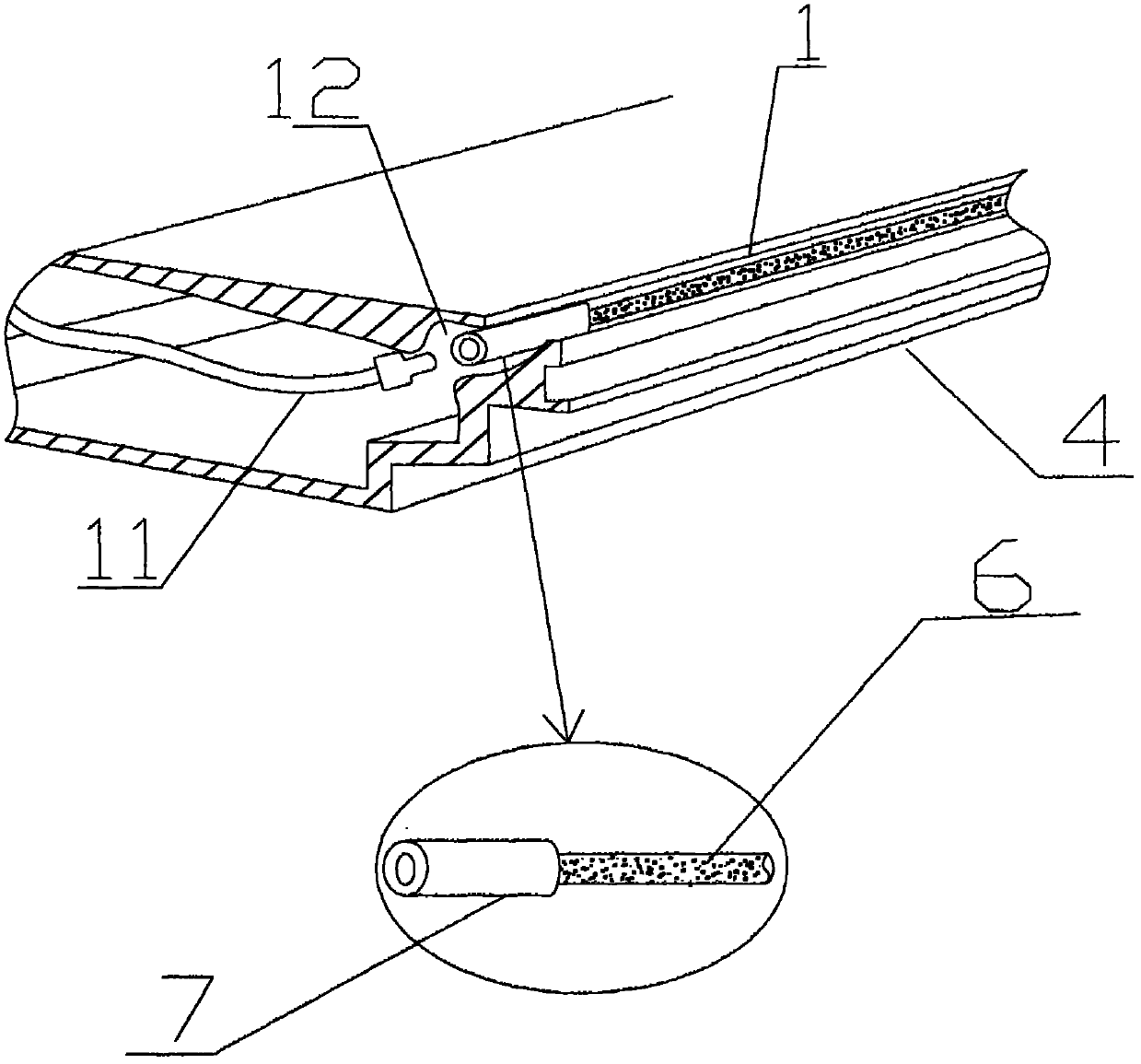

[0019] Such as figure 1 and figure 2 As shown: on the upper part of the convex joint groove 4 and the concave joint groove 3 on the left and right sides of the aluminum alloy floor body 2, inserting grooves capable of accommodating PE heating wires are respectively reserved. The PE heating wire 6 runs through the entire aluminum alloy floor after being inserted into the wire inlet 5 of the insertion groove, and returns to another installation unit from the wire outlet 1 of the insertion groove, and so on. Another example: the heating wire 6 penetrates through the threading hole entrance 101 arranged in the cavity of the aluminum alloy floor, passes through the entire floor, and passes through the threading hole exit 102 . On the support structure 8 of the floor, there is a wire gap 9 to allow the transition of the heating wire. In this way, the laying unit of the heating wire is completed, and the cycle is like this. The heating wire threading hole shown in the figure can o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com