Savonius wind rotor of small-type wind driven generator

A wind turbine and wind wheel technology, applied in the field of wind wheels, can solve the problems of reduced power generation system life, unsightly wind wheels, heavy blades, etc., and achieve the effects of light weight, reduced vibration, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

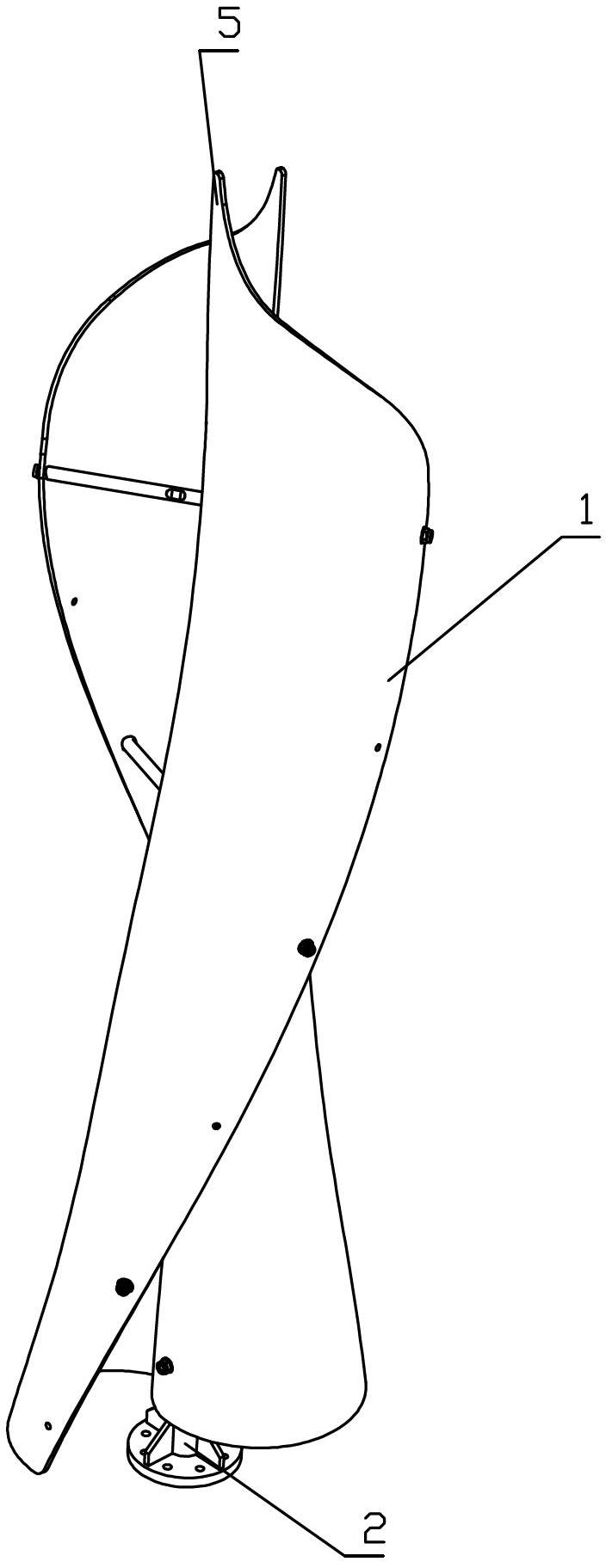

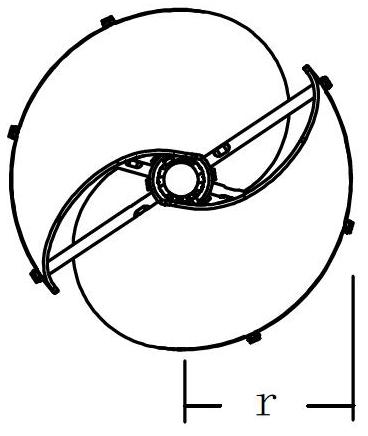

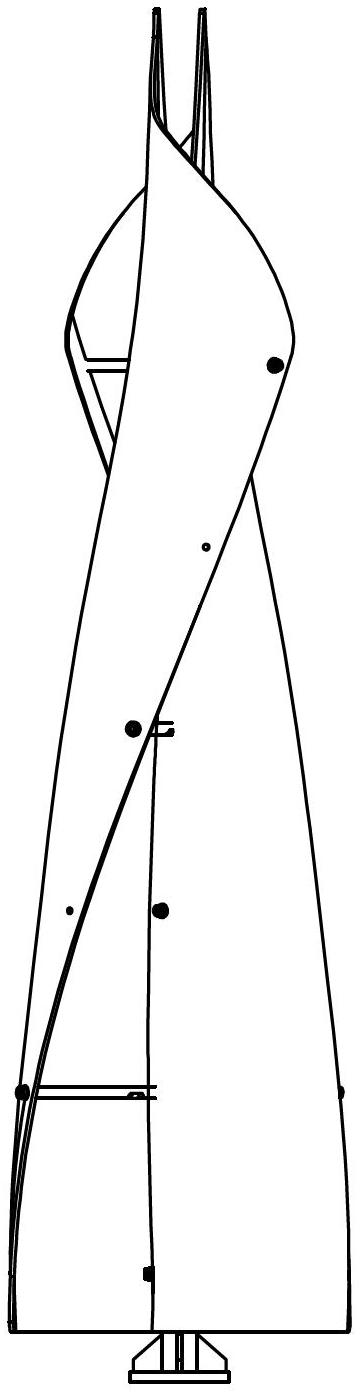

[0027] Embodiment 1: as Figure 1 to Figure 14 As shown, a wind rotor of a Sarnius small-scale wind power generator includes two blades 1, pillars 2, and connectors. Each blade 1 is connected to the pillars through connectors, and the connectors are divided into long connectors 4 and short connectors. piece 3. The orthographic projection of the edge line of the upper end of each blade 1 on the vertical plane passing through the axis of the pillar is a curve or a broken line or a straight line. In this projection, the horizontal height of the corresponding projection of the edge line near the end of the pillar 2 is D1, the horizontal height of the corresponding projection of the end of the edge line away from the pillar is D2, and D1 is greater than D2.

[0028] The shape of the curve is a smooth curve.

[0029] The end of the edge line that is far away from the pillar is smoothly transitioned to the edge line connected to this end in the blade, and in this example, the edge ...

Embodiment 2

[0097] Embodiment 2: The number of blades is three or more, which can be determined according to design requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com