Air floatation structure of separated type air foot

A split-type, air-floating technology, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of gas foot gas vibration and affect the gas foot stability, etc. Effect of small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

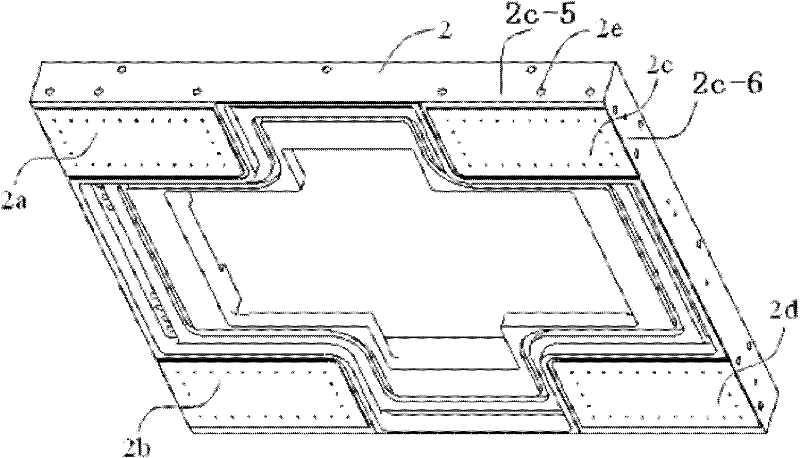

[0027] The following will combine Figure 2 ~ Figure 6 The air flotation structure of the split air foot of the present invention is further described in detail.

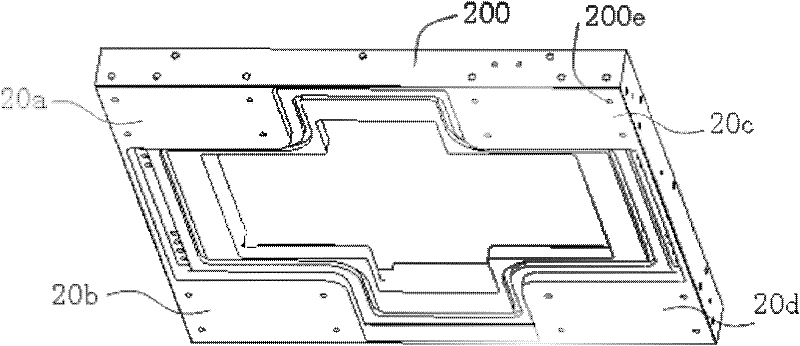

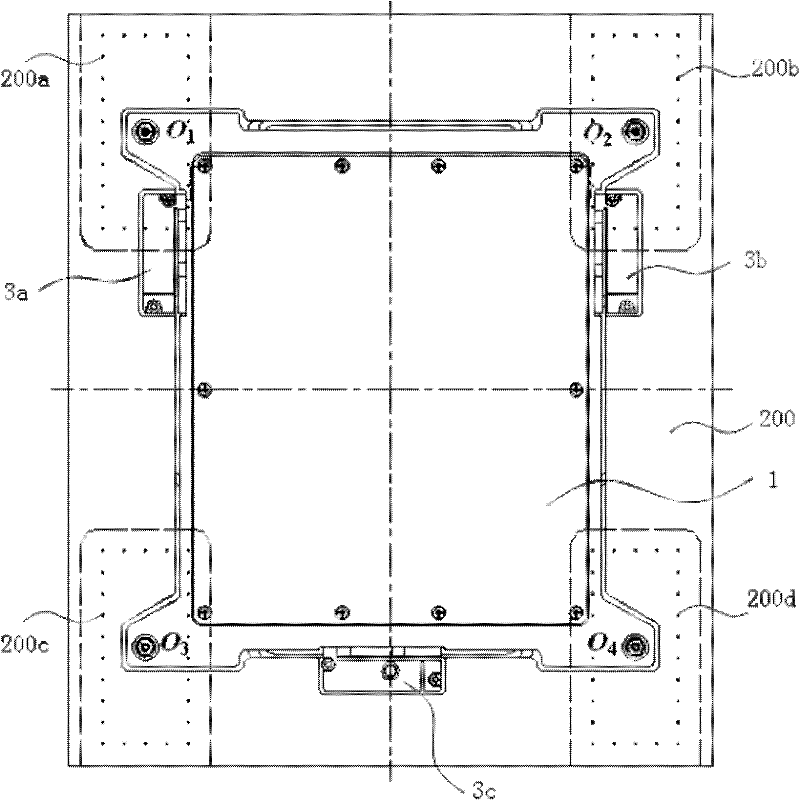

[0028] see figure 2 and image 3 , a split air foot, placed on the platform ( figure 2 (not shown in ), the split type air foot includes an air foot plate 200, the four corners of the bottom of the air foot plate 200 are respectively provided with an air flotation structure 200a, 200b, 200c and 200d, and the air foot plate 20000 Equipped with a vacuum preload structure 1;

[0029] Optionally, the air flotation structures 200a, 200b, 200c, and 200d can be formed by processing the air foot plate 200, that is, the air flotation structures 2a, 2b, 2c, and 2d are formed with the air foot plate 200. One;

[0030] continue to see figure 2 , the vacuum preload structure 1 is connected to the air foot plate 200 in a split type, and the four connection points O between the vacuum preload structure 1 and the air foot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com