Planetary roller screw assembly

A planetary roller and screw pair technology, applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problem that the axial gap between the roller and the screw cannot be completely eliminated, and achieve the goal of eliminating the axial gap Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

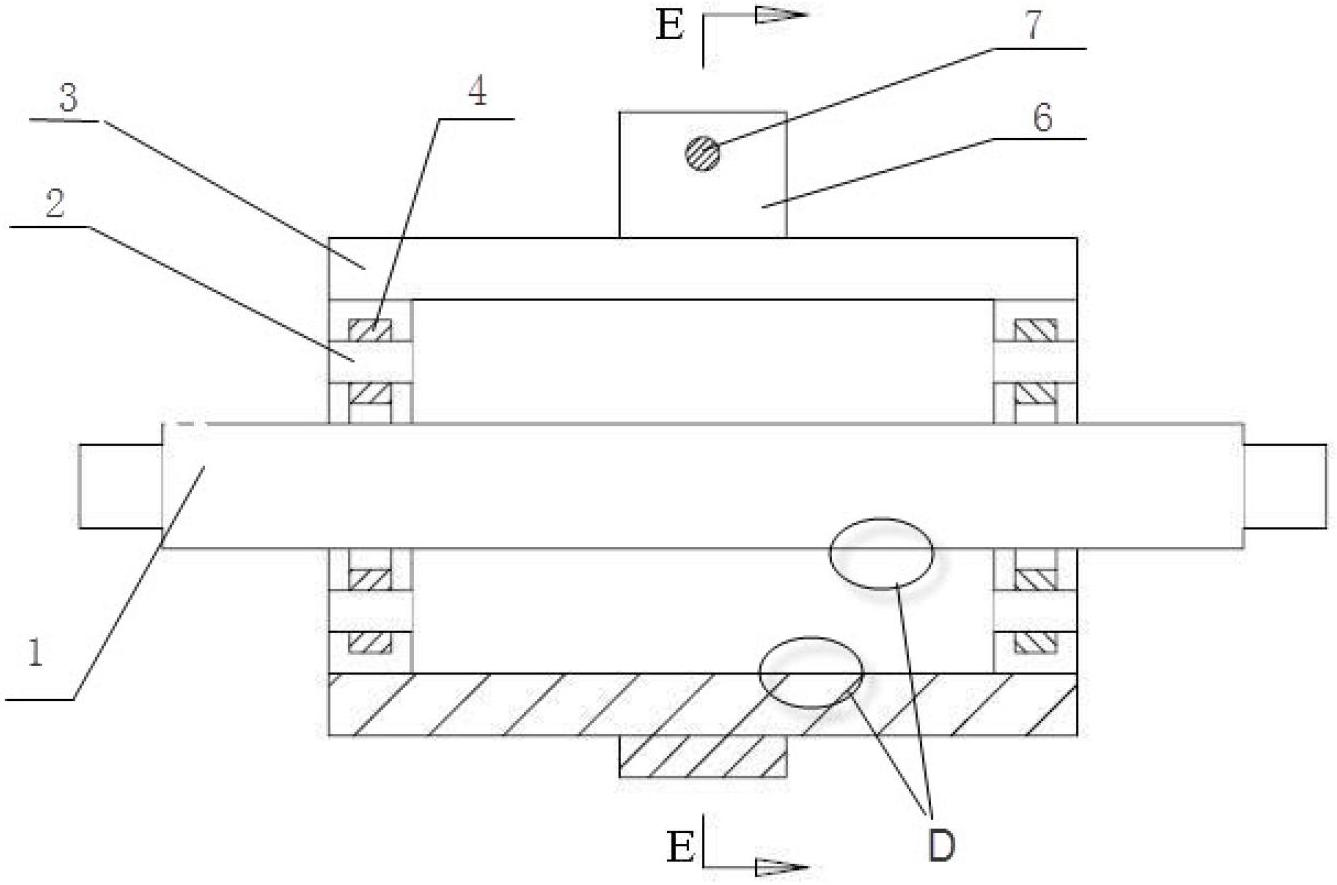

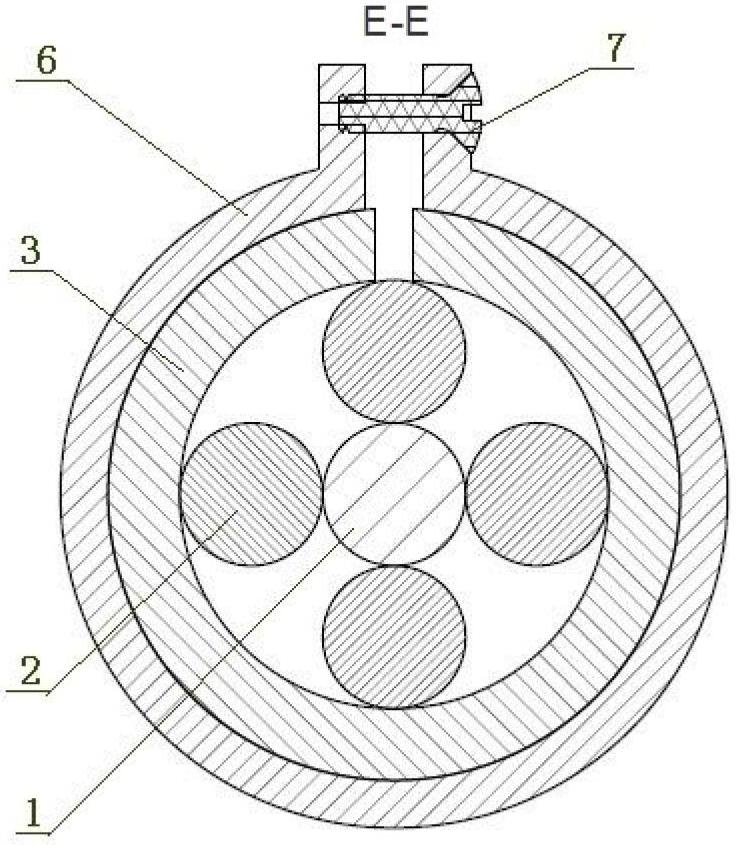

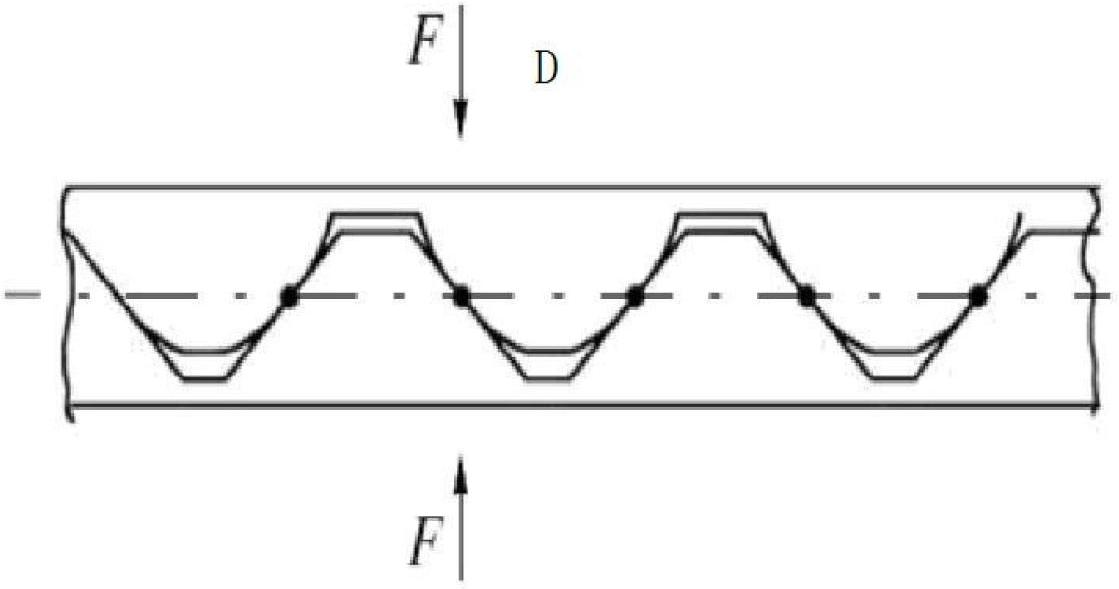

[0022] refer to Figure 1~5 , The planetary roller screw pair of the present invention includes a screw 1, a roller 2, a nut 3, a cage 4, a gap adjustment ring 6 and a gap adjustment screw 7. Among them, the lead screw 1, the roller 2 and the nut 3 have the same pitch, and the nut 3 has multi-thread threads, the tooth shape is triangular, and the tooth angle is 90°; the external thread of the lead screw 1 is the same as the internal thread of the nut 3. The number of heads and tooth type; the roller 2 is a single-start thread, and the side surface of the thread is designed to be arc-shaped, so that the contact between the roller, the nut and the screw is a point contact. The cage 4 is an annular structure with a thickness of 3-5mm, and has the same number of holes as the rollers 2 to fix the shaft ends of the rollers 2. The nut 3 is made of high-strength alloy steel, and the pre-processing technology is consistent with the traditional structure. After the thread of the nut 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com