Method for adjusting gas flow in analysis of automotive tail gas

A technology of automobile exhaust and gas flow, applied in the direction of analyzing materials, analyzing materials through optical means, measuring devices, etc., can solve the problems of high cost, complicated circuit, and affecting measurement accuracy, and achieve increased measurement accuracy, simple use, and high function Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

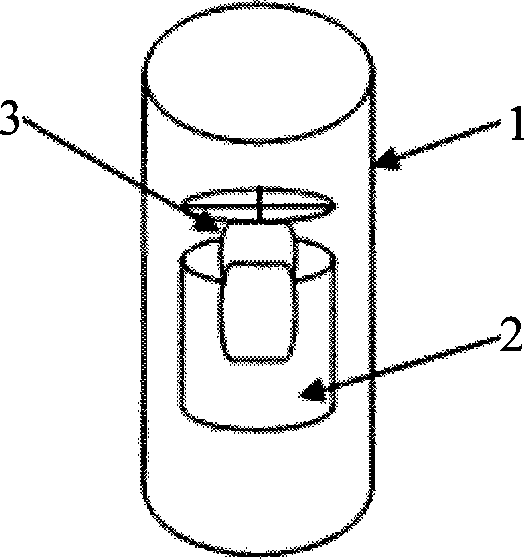

[0014] To provide a method for adjusting the gas flow rate in automobile exhaust gas analysis, that is, to design the air resistance structure used in the automobile exhaust gas analyzer to adjust the flow rate, and to design the air resistance-air capacity structure similar to the principle of resistance-capacitance in the circuit. Has a good smoothing effect.

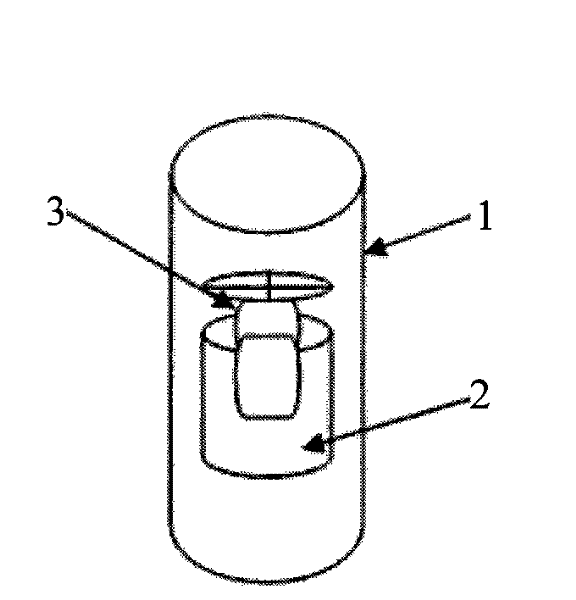

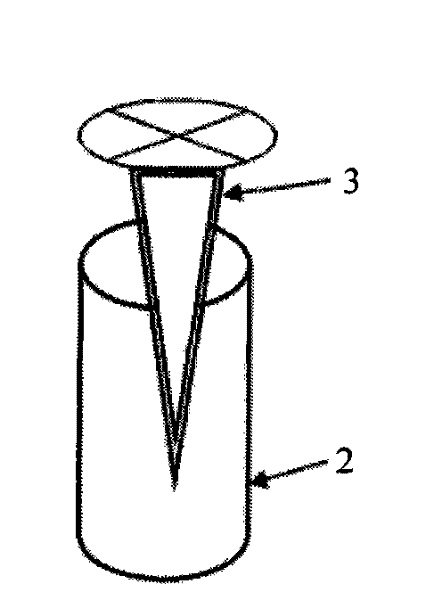

[0015] Such as figure 1 , figure 2 As shown, the air resistance structure used in the automobile exhaust gas analyzer mainly includes an air hose 1, a plastic pipe 2 and a self-tapping screw 3, and a plastic pipe 2 with a changeable outer diameter is inserted into the air hose 1, A conical self-tapping screw 3 is screwed into the plastic tube 2; wherein, the ratio of the outer diameter of the plastic tube 2 to the inner diameter of the air hose 1 is 1:1.05 to 1:1.15, and the specific material of the plastic tube is nylon 1010.

[0016] In specific applications, by adjusting the position where the self-tapping scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com