Anti-stripping deep hole cleaning combination brush

A combined brush and anti-stripping technology, which is applied in the post-processing field of castings, can solve the problems of easily damaged universal radial drilling machines, waste of materials and labor, and low work efficiency, so as to improve cleaning effects, reduce cleaning costs, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

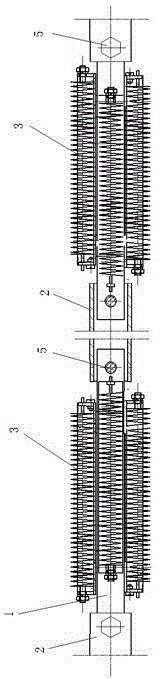

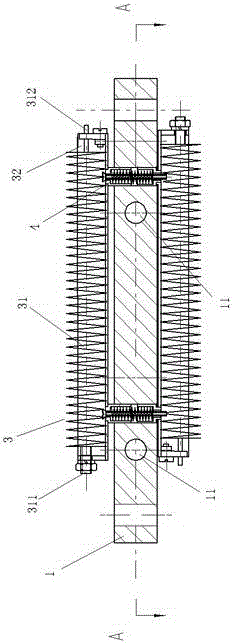

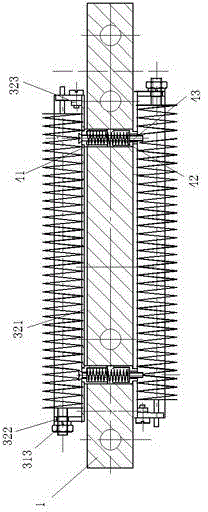

[0020] Such as Figure 1 ~ Figure 4 As shown, the present invention includes a plurality of support rods 1, a plurality of connecting sleeves 2, a plurality of sets of brush assemblies 3 and a plurality of elastic support mechanisms 4, and each set of brush assemblies 3 is arranged in parallel on the support rod 1 in pairs and up and down. Outside the side. The support rod 1 of this embodiment is a quadrangular prism structure with a square cross-section. Two groups of four brush assemblies 3 are evenly distributed on the four sides of the support rod 1 . The elastic supporting mechanism 4 in the hole 11 is connected, and the two groups of brush assemblies 3 are longitudinally staggered and the axes intersect at 90°. This embodiment is used to clean the main oil passage hole 5 of Φ100mm aperture of the L27 / 38 type marine diesel engine. There are two groups of four bru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com